Black silicon methyl sulfonyl methane (MSM) structure photoelectric detector and preparation method thereof

A technology of photodetector and black silicon, which is applied in the field of photodetector, can solve the problem of low sensitivity and achieve the effect of high responsivity and wide spectral response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

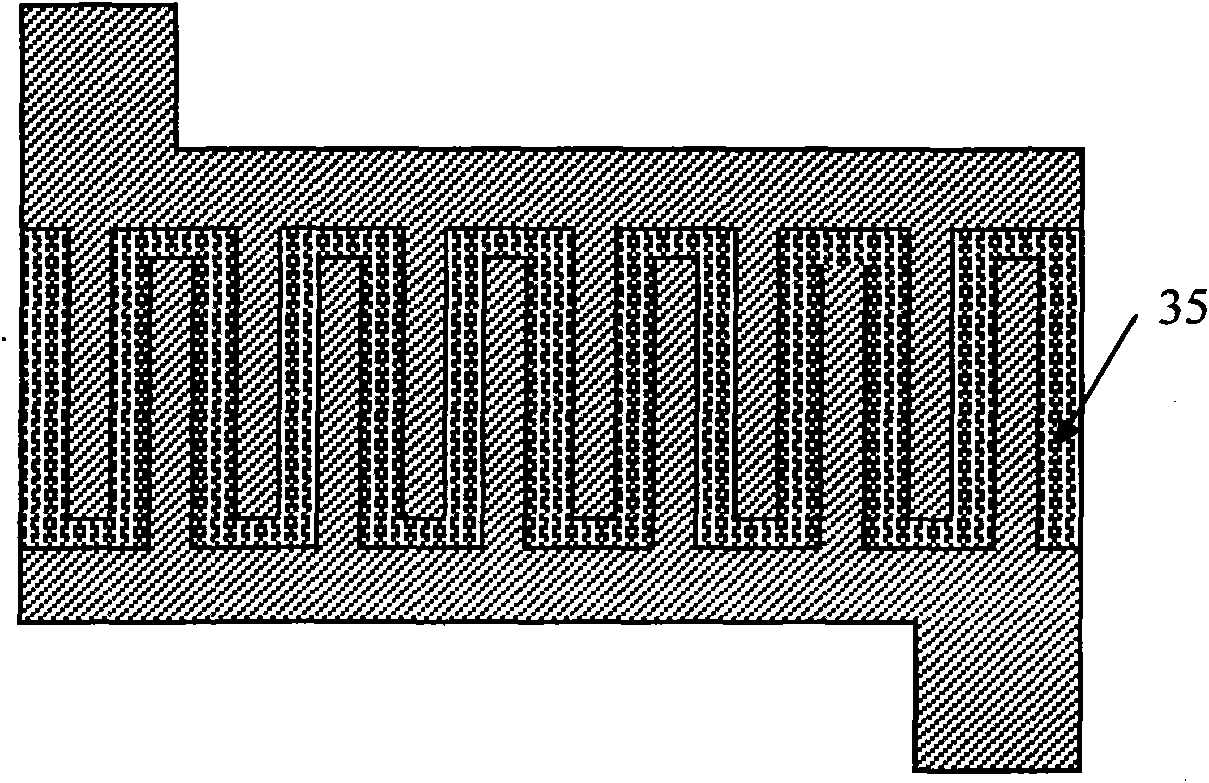

preparation example Construction

[0031] The preparation method includes the following steps: ①Preparing a black silicon thin film layer: implanting doping materials on a single crystal silicon substrate by ion implantation to prepare a surface microstructure; ②Spin-coating a layer of photoresist on the surface of the black silicon thin film layer , and use a specific interdigitated electrode mask pattern to pattern the photoresist; ③ immerse the patterned substrate in an alkali etching solution to etch, and remove the unprotected black silicon film layer on the pattern; ⑤ Deposition barrier ④ using the overlay process to prepare the interdigitated electrode pattern again; ⑥ then deposit the electrode material layer and pattern it into the shape of the interdigitated electrode; ⑦ deposit the passivation layer; ~40 minutes.

[0032] The doping material for ion implantation in step ① is S or Se or Te, and the doping concentration range is 1×10 14 and 5×10 15 ion / cm 2 between.

[0033] The preparation of the ...

Embodiment 1

[0038] The specific implementation steps are as follows:

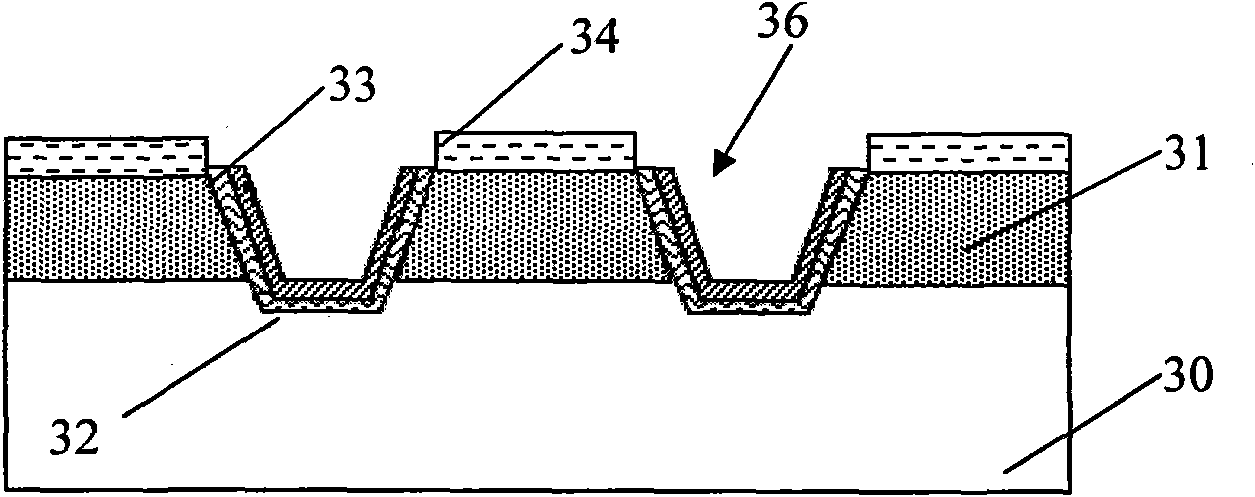

[0039] 1. Prepare the black silicon material 31, the thickness of the obtained black silicon layer is 1-10 μm.

[0040] 2. Spin-coat a layer of photoresist on the surface of the black silicon material, and pattern the photoresist with a specific interdigitated electrode mask pattern.

[0041] 3. Immerse the patterned substrate in the alkaline etching solution for a specific period of time to remove the unprotected black silicon layer on the pattern.

[0042] 4. Corrosion in a specific concentration of KOH solution to form a U-shaped structure 36, and the depth of the U-shaped groove is 3-10 μm.

[0043] 5 Prepare the interdigitated electrode pattern above the U-shaped groove by using the overlay process;

[0044] 6. Deposit a thin a-Si:H barrier layer 32 with a thickness of about 30-100 nm.

[0045] 7. Deposit a metal Al or ITO thin film with a thickness of about 50-100 nm as the interdigital electrode material 33, ...

Embodiment 2

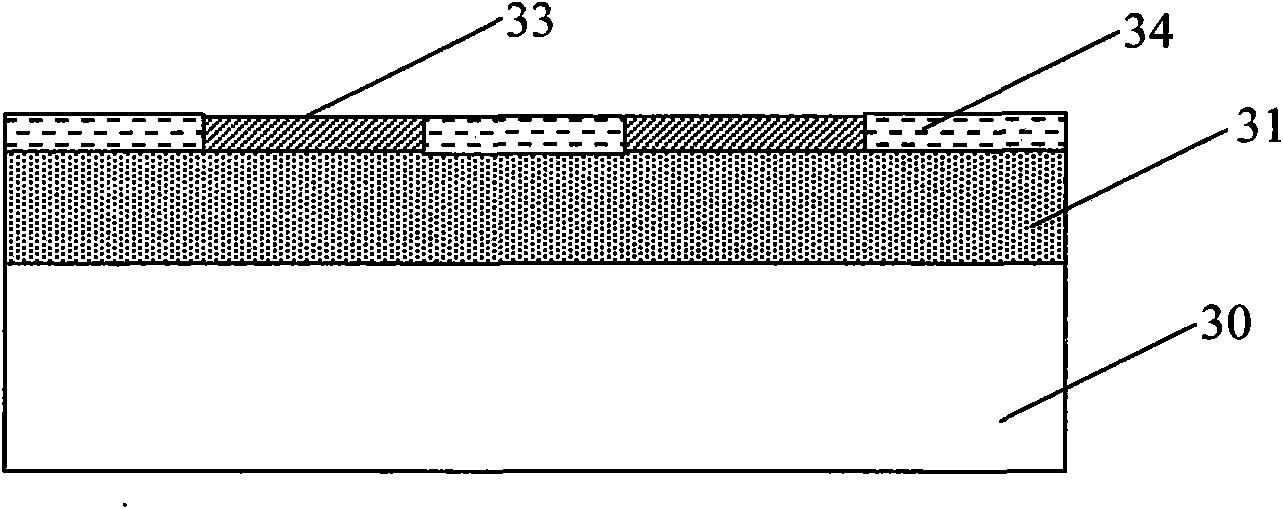

[0050] The difference between this implementation example and implementation example 1 is that step 3, step 4 and step 5 are cancelled, and the rest are the same as example 1.

[0051] The resulting device structure is as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com