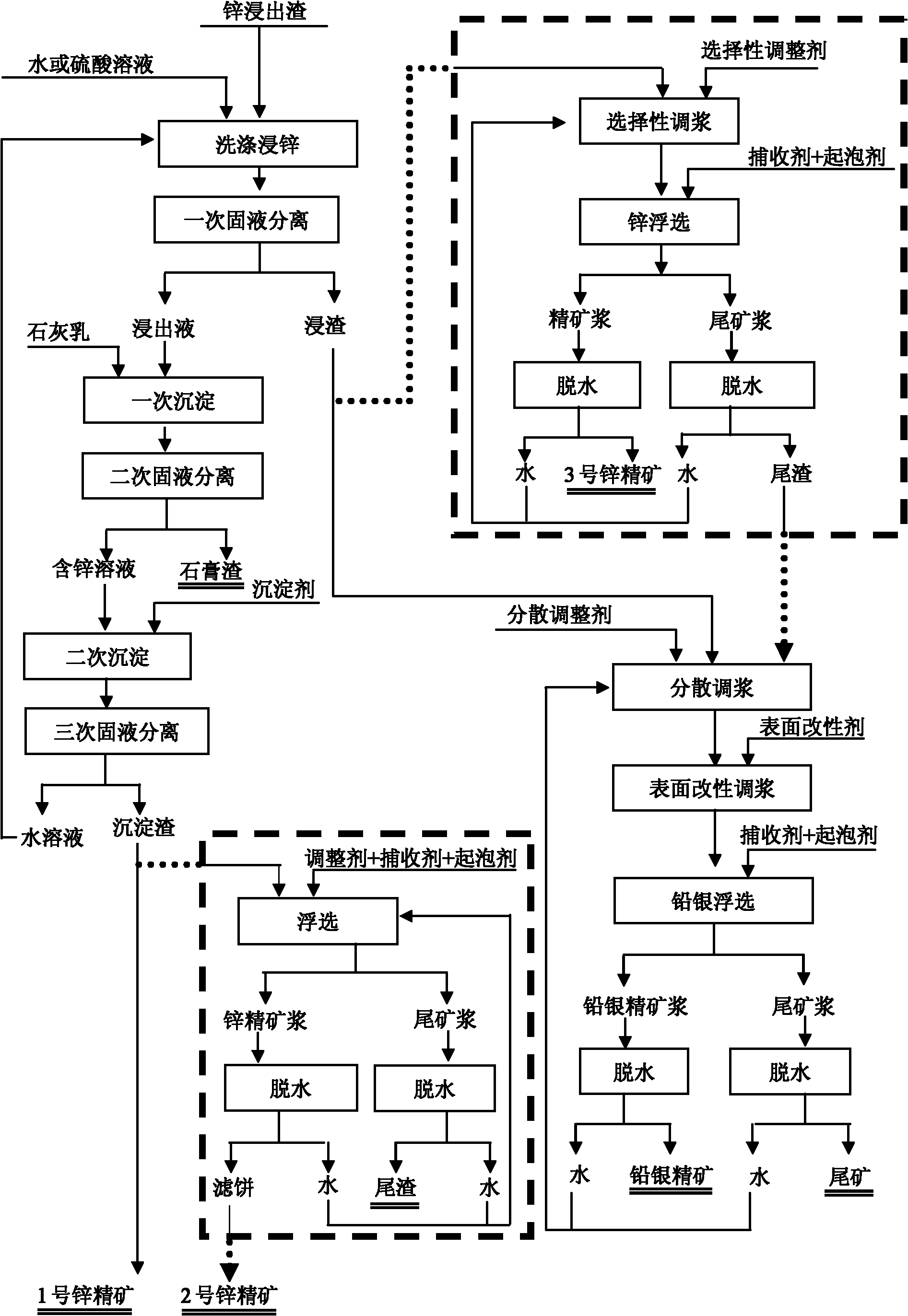

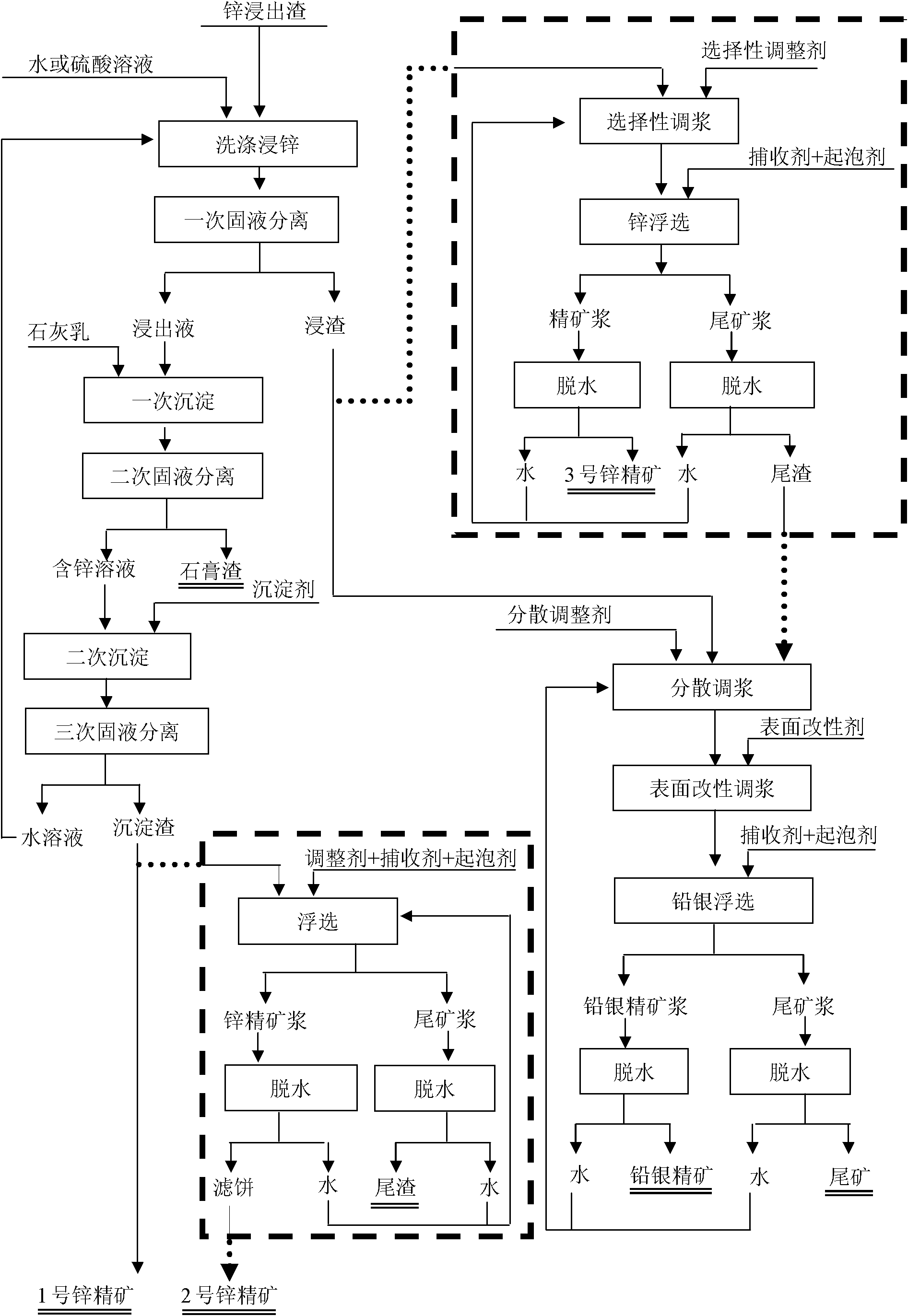

Beneficiation method for recovering zinc, lead and silver from zinc leaching residue

A beneficiation method and zinc leaching slag technology are applied in the field of recovering lead and silver from zinc leaching slag, and in the field of zinc, which can solve the problems of inability to recover lead and silver, and achieve low production costs, eliminate potential safety hazards, and reduce equipment costs. The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0088] Zinc leaching slag contains 5.1% lead, 4.8% zinc and 125g / t silver.

[0089] Weigh 1000 grams of the slag, add 500 ml of water, grind the ore in a ball mill for 2 minutes, add water to the ground pulp to make a pulp with a solid concentration of about 20%, add sulfuric acid solution to the pulp, stir for 10 minutes, and leaching Endpoint pH = 0.5. Then the pulp was vacuum filtered to obtain 3750 ml of leachate containing 6.7 g / l of zinc and a zinc leaching rate of 52.34%. 865 grams of leaching residue was obtained, containing 5.9% lead and 145g / t silver.

[0090] Add milk of lime to the leaching solution, adjust the pH of the slurry to 4.0, obtain 87 grams of gypsum slag after solid-liquid separation, containing 0.85% zinc, and the loss rate of zinc in the gypsum slag from the leachate is 2.94%. Add milk of lime to the solution of pH=4.0, adjust the pH of the pulp to 8.5, and obtain 124 grams of precipitated residue after solid-liquid separation again, containing 19.3...

example 2

[0096] Ore sample is identical with example 1, except that following steps are different from example 1, all the other steps are all the same as example 1. Add sulfuric acid solution in the washing and zinc dipping stage, stir for 30 minutes, and the pH of the leaching end point is 1.4. After solid-liquid separation, 3820ml of leachate is obtained, containing 6.1g / l of zinc, and the zinc leaching rate is 48.55%. 877g of leaching residue was obtained, containing 5.8% lead and 143g / t silver.

[0097] Add milk of lime to the 3820ml leachate to adjust the pH of the slurry to 5.0. After solid-liquid separation, 89 grams of gypsum slag is obtained, containing 0.82% zinc. The loss rate of zinc in the gypsum slag from the leachate is 3.13%. Add sodium hydroxide solution to the solution at pH=5.0, adjust the pH of the pulp to 9.0, and obtain 54.6 grams of precipitated residue after solid-liquid separation again, containing 40.64% zinc, the solution contains 0.1g / l zinc, and the zinc lo...

example 3

[0100] Ore sample is identical with example 1, except that following steps are different from example 1, all the other steps are all the same as example 1. In the leaching stage, sulfuric acid solution was added and stirred for 50 minutes. The pH of the leaching end point was 3.0. After solid-liquid separation, 3780ml of leachate was obtained, containing 5.9g / l of zinc, and the zinc leaching rate was 46.46%. 892 grams of leaching residue was obtained, containing 5.7% lead and 140g / t silver.

[0101] Add milk of lime to the 3780ml leaching solution to adjust the pH of the slurry to 5.8. After solid-liquid separation, 32 grams of gypsum slag are obtained, containing 1.5% zinc. The loss rate of zinc in the gypsum slag is 2.15%. In the solution of pH=5.8, add concentration again and be 30% sodium sulfide solution 110ml, obtain precipitation slag No. 1 zinc concentrate after solid-liquid separation again, weigh 41.6 grams, contain zinc 51.52%, solution contains zinc 0.1g / l, The zi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com