Method and special enzymic preparation for preparing ultra-high maltose syrup

A maltose syrup and ultra-high technology, applied in the field of preparation of ultra-high maltose syrup, can solve problems such as complex process, and achieve the effects of simple process, strong maltose generating capacity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: the preparation of ultra-high maltose syrup

[0030] Liquefaction: Prepare 100 kg of corn starch into starch milk with a concentration of 10%-30%, adjust the pH to 4.5-6.5, heat to 95-105°C, add high-temperature-resistant acid a-amylase, and the amylase dosage is 2- 8 LU / g dry starch, liquefy for 10-25 minutes, inactivate enzyme at 135°C for 5 minutes, control DE value between 1-8;

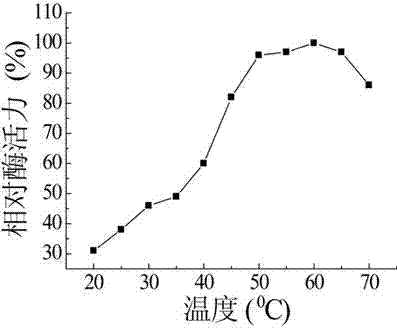

[0031] Saccharification: Cool to 55-65°C after liquefaction, add fungal a-amylase RoAmy, the dosage is 4-15 U / g dry starch, during this period, use high-pressure liquid chromatography (HPLC) to measure the formation of glucose, maltose and other oligosaccharides After 30-60 hours of saccharification, decolorization, ion exchange, and vacuum concentration to a concentration of 70%-80%, 125-140 kg of ultra-high maltose syrup with a maltose content of 65%-75% was obtained.

Embodiment 2

[0032] Example 2: Cloning of fungal α-amylase RoAmy

[0033] Extract total RNA from Rhizopus oryzae tissue, using the following oligonucleotides as primers:

[0034] Upstream primer: 5'-ATCATGAAGTCTTTTCTTAAGTCTCCTTTGCA-3',

[0035] Downstream primer: 5'-CTGCCCGGGTTATTTCTTTTGGAA-3'

[0036] Using a reverse transcription PCR kit to amplify to a size of 1.4 kb Ro Amy The cDNA fragment of the gene was recovered and cloned into pMD19, and the recombinant plasmid pMD- Ro Amy , extract the recombinant plasmid and sequence it using T-vector universal primers to determine Ro Amy The cDNA sequence of the gene is SEQ ID NO:1.

Embodiment 3

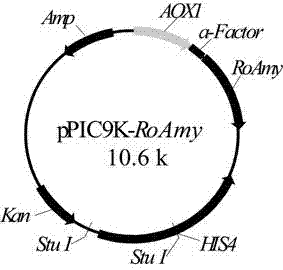

[0037] Example 3: Construction of Yeast Expression Fungal α-amylase RoAmy Vector

[0038] With the recombinant plasmid pMD- Ro Amy As a template, the following oligonucleotides are used as primers

[0039]Upstream primer: 5'-ATCATGAAGTCTTTTCTTAAGTCTCCTTTGCA-3',

[0040] Downstream primer: 5'-CTGCCCGGGTTATTTCTTTTGGAA-3'

[0041] Using a high-fidelity DNA polymerase ( Pfu DNA polymerase) amplified Ro Amy gene fragments, recovery Ro Amy The gene fragment was inserted into the pPIC9K vector (from Invitrogen) in a blunt-end manner Snap BI site to obtain the yeast expression vector pPIC9K- Ro Amy .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com