Method for enhancing radiation resistant characteristic of LDMOS (Laterally Diffused Metal Oxide Semiconductor)

An anti-radiation and characteristic technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve problems that affect the reliability of devices and circuits, increase electric fields, and reduce breakdown voltage of devices, so as to improve anti-radiation ability, improve radiation resistance, and reduce the effect of reinforcement costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In the preparation of the integrated circuit of the present invention, the materials used to form the trench isolation region and the drift region dielectric layer of the N-type and P-type LDMOS devices are different, so the process steps for the preparation of the N-type and P-type LDMOS transistor isolation regions and the drift region are separated. , the process is as follows:

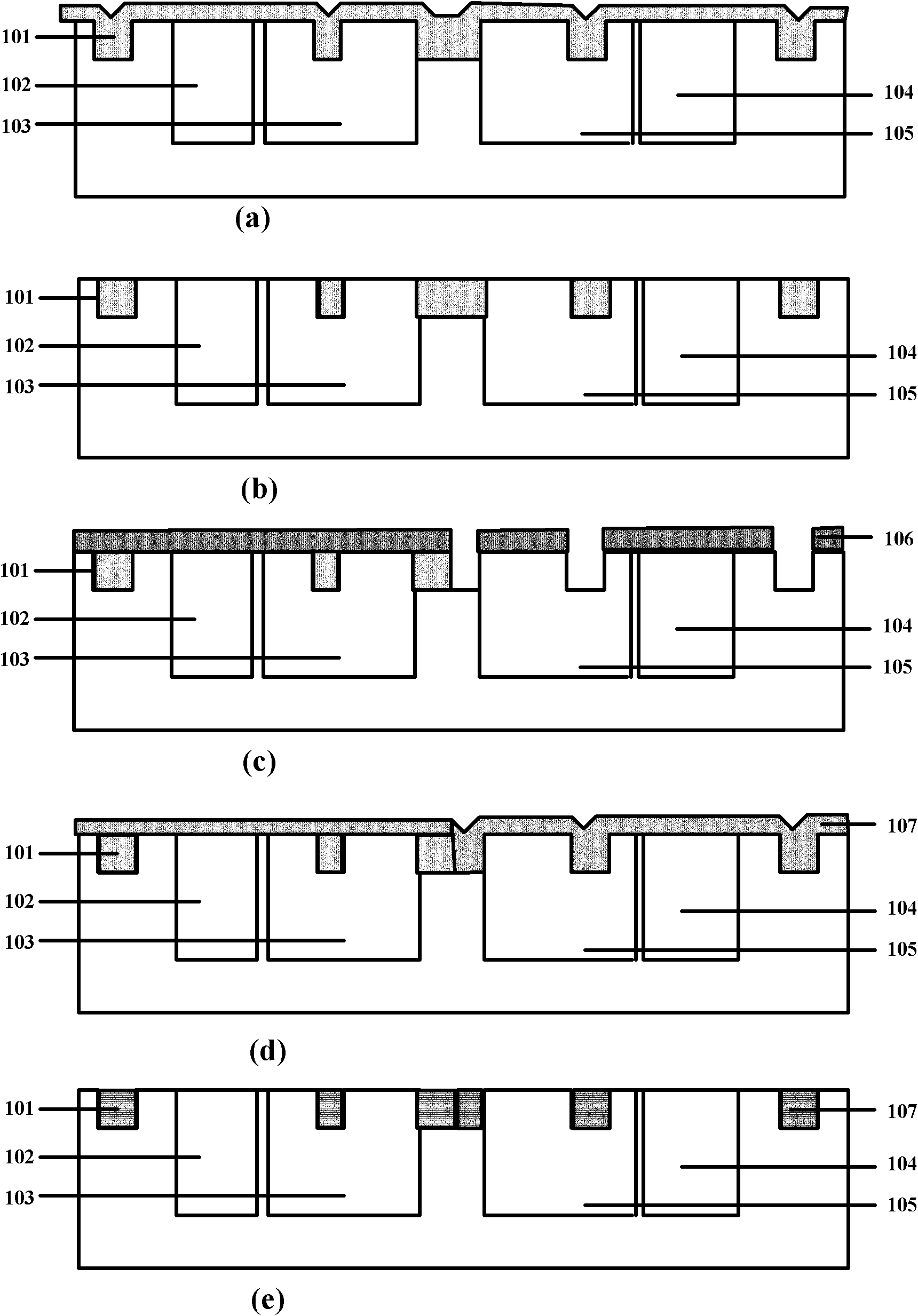

[0018] image 3 (a)-(e) are the process flow and the cross-sectional schematic diagrams corresponding to each step of the method for preparing the isolation region and the drift region of the N-type and P-type LDMOS devices of the present invention.

[0019] 101---deposited silicon dioxide; 102---N well body region of P-type LDMOS transistor; 103---P well drift region of P-type LDMOS transistor; 104---P well of N-type LDMOS transistor Body region; 105---N well drift region of N-type LDMOS transistor; 106---photoresist; 107---nitride medium.

[0020] The specific process of the dielectric l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com