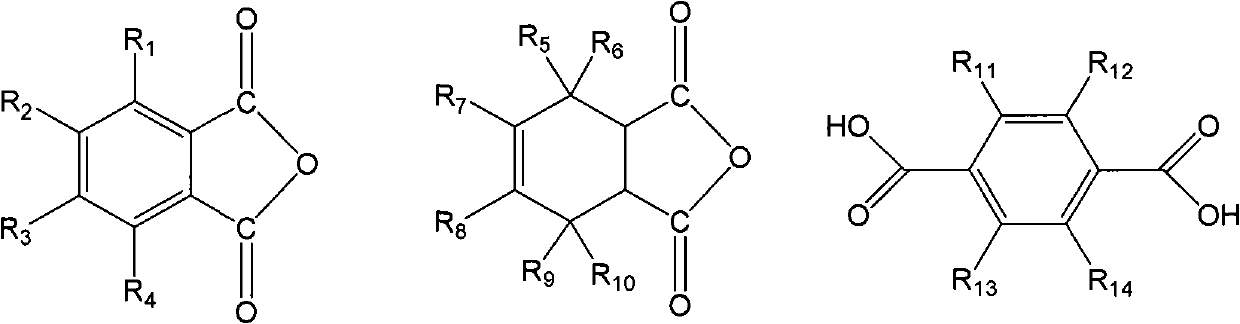

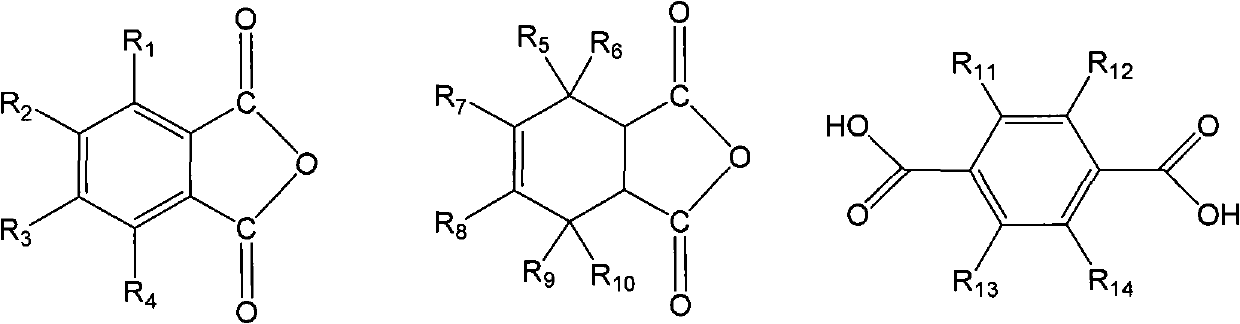

Aromatic polyester modified polyether polyol and preparation method thereof

A technology of polyether polyol and polyester polyol, applied in the field of modified polyether polyol and its manufacturing, can solve the problems of poor mutual solubility, poor compressive strength and dimensional stability of polyurethane, and achieve easy operation, good compressive strength, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of modified polyether polyols

[0030] Add 212kg of diethylene glycol (2mol) into the reactor, heat up while stirring, then add 148kg of phthalic anhydride (1mol) under stirring, and finally add 72g of catalyst tetraisobutyl titanate (accounting for diethylene glycol and phthalic anhydride) 0.2‰ of the total amount of diformic anhydride), heat up and control the temperature at about 210°C, react for 7 hours, cool down to 120°C and start vacuuming for 1.5 hours to obtain 342kg aromatic polyester polyol; when the temperature drops to within 100°C, Vacuum suction 180kg of sucrose, and carry out nitrogen replacement 3 times, inhale 7.5kg concentration under negative pressure and be 40wt% dimethylamine aqueous solution (accounting for 0.8% of reactant total mass), be warming up to 110 ℃, in 3 hours divide into three Add 400kg of propylene oxide (accounting for 43% of the total mass of the reactant) in batches, and make the reaction pressure not exceed 0.4Mpa, ...

Embodiment 2

[0039] 1. Add 123kg glycerol (1.34mol) to the reactor, heat up while stirring, then add 148kg phthalic anhydride (1mol) under stirring, and finally add 54.2g of catalyst tetraisobutyl titanate (accounting for two 0.2‰ of the total amount of glycol and phthalic anhydride), heat up and control the temperature at 200°C, react for 7.5 hours, cool down to 105°C and start vacuuming for 1-2 hours to obtain 253kg aromatic polyester polyol; when the temperature drops to 100 When within ℃, vacuum suction solid sorbitol 198kg, and carry out nitrogen replacement 3 times, inhale 12kg concentration under negative pressure and be the dimethylamine aqueous solution (accounting for 1.14% of reactant gross mass) of 40wt%, be warming up to 105 ℃, in Add 600kg of propylene oxide (accounting for 57% of the total mass of the reactants) in three batches within 3 hours, and make the reaction pressure not exceed 0.4Mpa, keep warm at 120-125°C for about 2.5 hours until the pressure is zero, and control ...

Embodiment 3

[0047] 1. Add 152kg (2mol) propylene glycol to the reactor, heat up while stirring, then add 148kg (1mol) phthalic anhydride under stirring, and finally add 60g of catalyst tetraisobutyl titanate (accounting for diethylene glycol and o-phthalic anhydride) 0.2‰ of the total amount of diformic anhydride), heat up and control the temperature at about 215°C, react for 8 hours, cool down to 120°C and start vacuuming for 1.5 hours to obtain 282kg aromatic polyester polyol; when the temperature drops below 100°C, vacuum Inhale solid sorbitol 182kg, and carry out nitrogen replacement 3 times, inhale 15kg concentration under negative pressure and be the dimethylamine aqueous solution (accounting for 1% of total mass of reactant) of 40wt%, be warming up to 105 ℃, in 3 hours divide into three Add 1020kg of propylene oxide (accounting for 69% of the total mass of the reactants) in batches, and make the reaction pressure not exceed 0.4Mpa, keep it warm at 120-125°C for about 2.5 hours until...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com