Purification method for straw gasified gas and equipment thereof

A gas and straw technology, applied in the field of purification of biomass gasification gas, can solve the problems of fuel humidity increase, poor combustion, no cracking tar, etc., meet the requirements of reducing fuel moisture content, avoid secondary pollution, and improve gasification efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

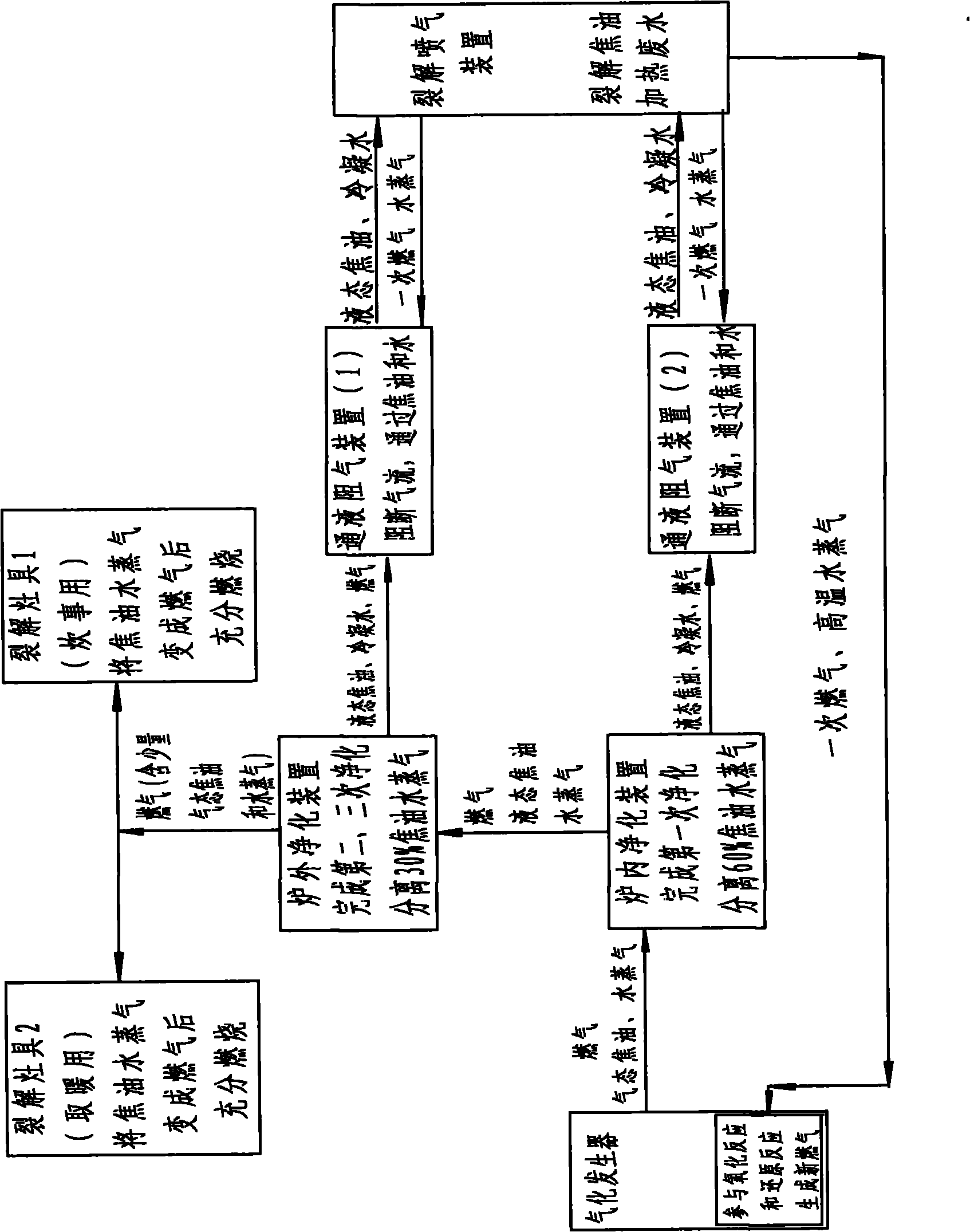

[0044] (1) overall structure of the device of the present invention

[0045] like figure 1 As shown, the equipment assembly of the present invention is composed of 6 devices: namely 1. gasification generator, 2. purifying device in the furnace, 3. purifying device outside the furnace, 4, liquid-passing and gas-blocking device (3), 5. Cracking jets. 6. Cracking cooker (1 to 2).

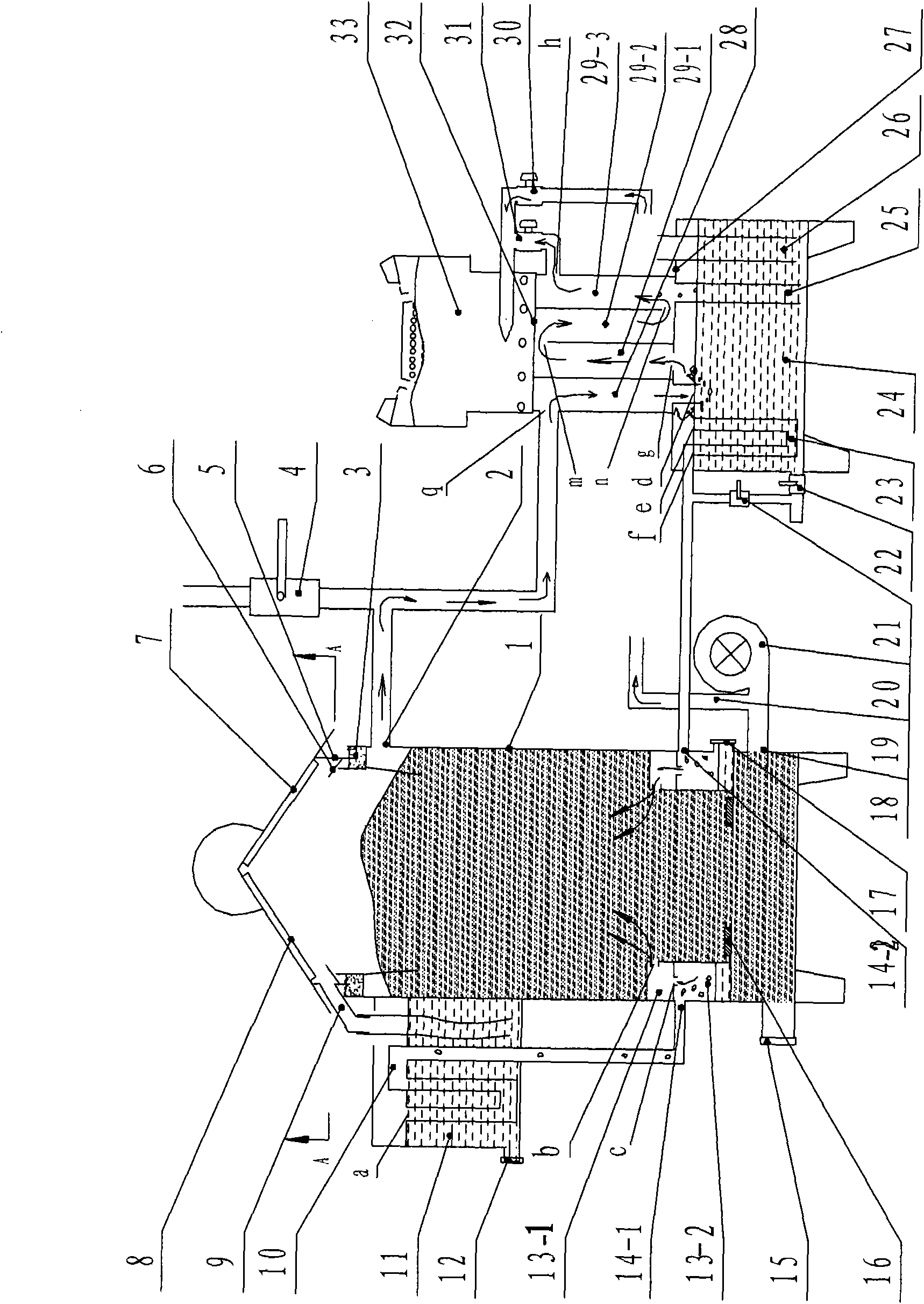

[0046] (2) the structure of each device of the present invention:

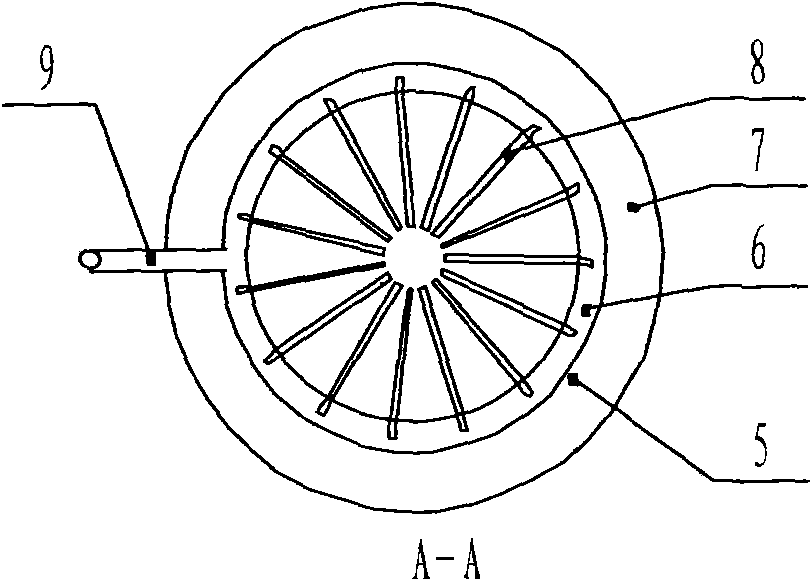

[0047] 1. Gasification generator adopts updraft gasification generator. see figure 2 , consists of cylinder body 1, gas outlet 2, exhaust valve 4, feeding cover 7, sealing plate 5, ash removal port 15, air distribution plate 16, and air inlet 18. The sealing plate 5 is arranged on the feeding cover 7, and its lower end edge is pressed into the sealing packing in the sealing ring groove 3 of the feeding port of the gasification generator. The gas outlet 2 of the gasification generator is connected in parallel with the exhaust val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com