GaN light-emitting diodes with low-temperature p-type GaN layer

A technology based on light-emitting diodes and gallium nitride, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as structural damage, the influence of light-emitting diodes, and the influence of device luminous intensity, and achieve the improvement of reverse breakdown voltage and luminous intensity. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

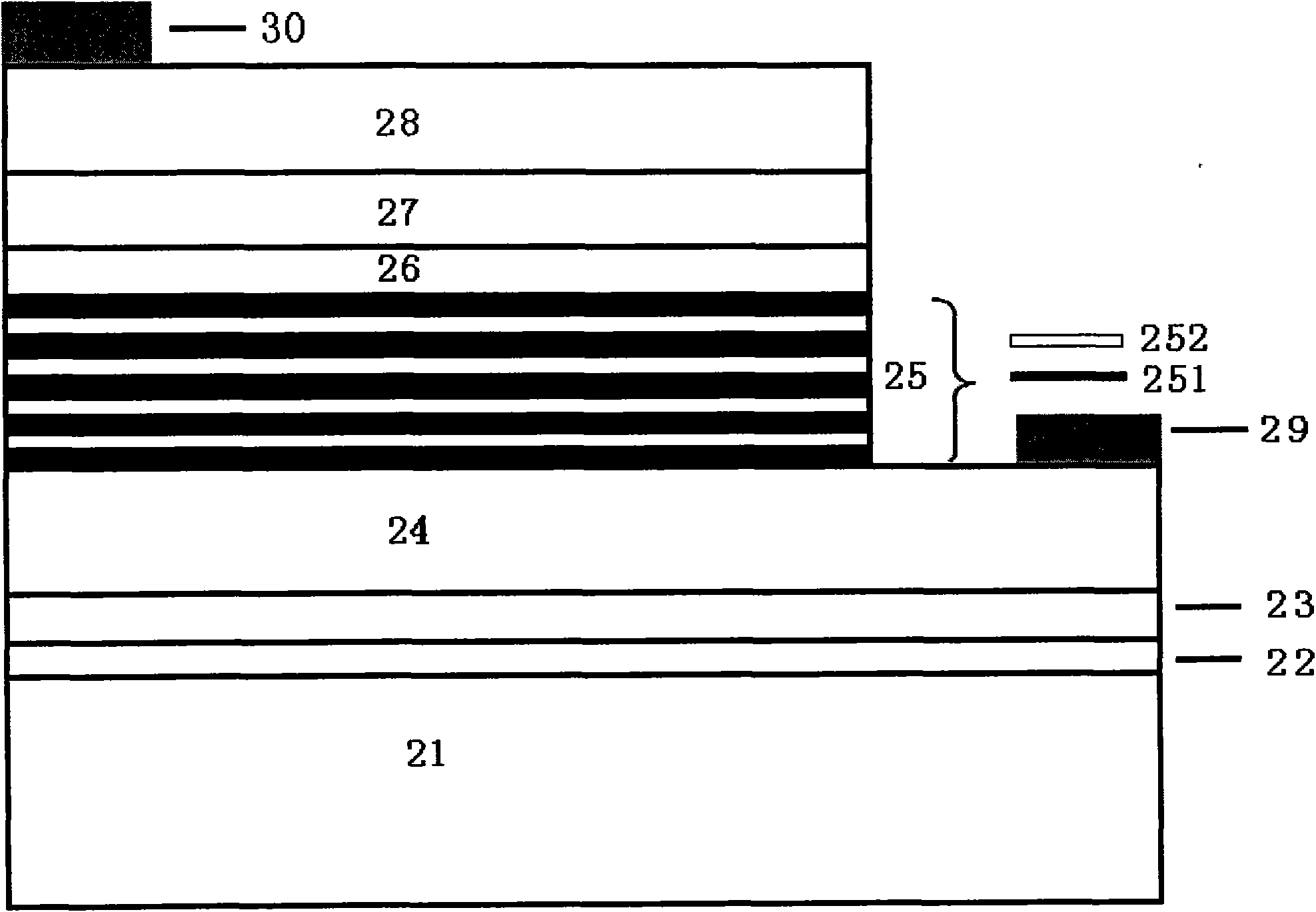

[0066] figure 2 Shown is a GaN-based light-emitting diode with a low-temperature p-type GaN insertion layer according to the present invention. It is manufactured under the same process conditions as Comparative Example 1, except that a low-temperature p-type nitride layer with a thickness of 20-100 nanometers is inserted between the InGaN / GaN multi-quantum well active light-emitting layer 25 and the p-type AlGaN electron blocking layer 27. Gallium insertion layer 26 , and the lower surface of the low-temperature p-type GaN insertion layer 26 is in contact with the GaN thin layer in the multi-quantum well active light-emitting layer 25 . The doping concentration of magnesocene in the low-temperature p-type gallium nitride layer is 10 19 ~10 21 cm -3 .

[0067] The specific growth conditions of the low-temperature p-type GaN insertion layer 26 are as follows: reaction temperature 600-900°C, reaction chamber pressure 200-500 Torr, carrier gas flow rate 5-20 liters / min, ammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com