Carbon nanotube composite material filled with ferrous sulfide, preparation method and application thereof

A technology of carbon nanotubes and composite materials, applied in nanostructure manufacturing, chemical instruments and methods, nanotechnology, etc., can solve the problems of limiting the wide application of carbon nanotube composite materials, cumbersome filling process, and complicated preparation process, and achieve The effect of controllable product characteristics, good controllability and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

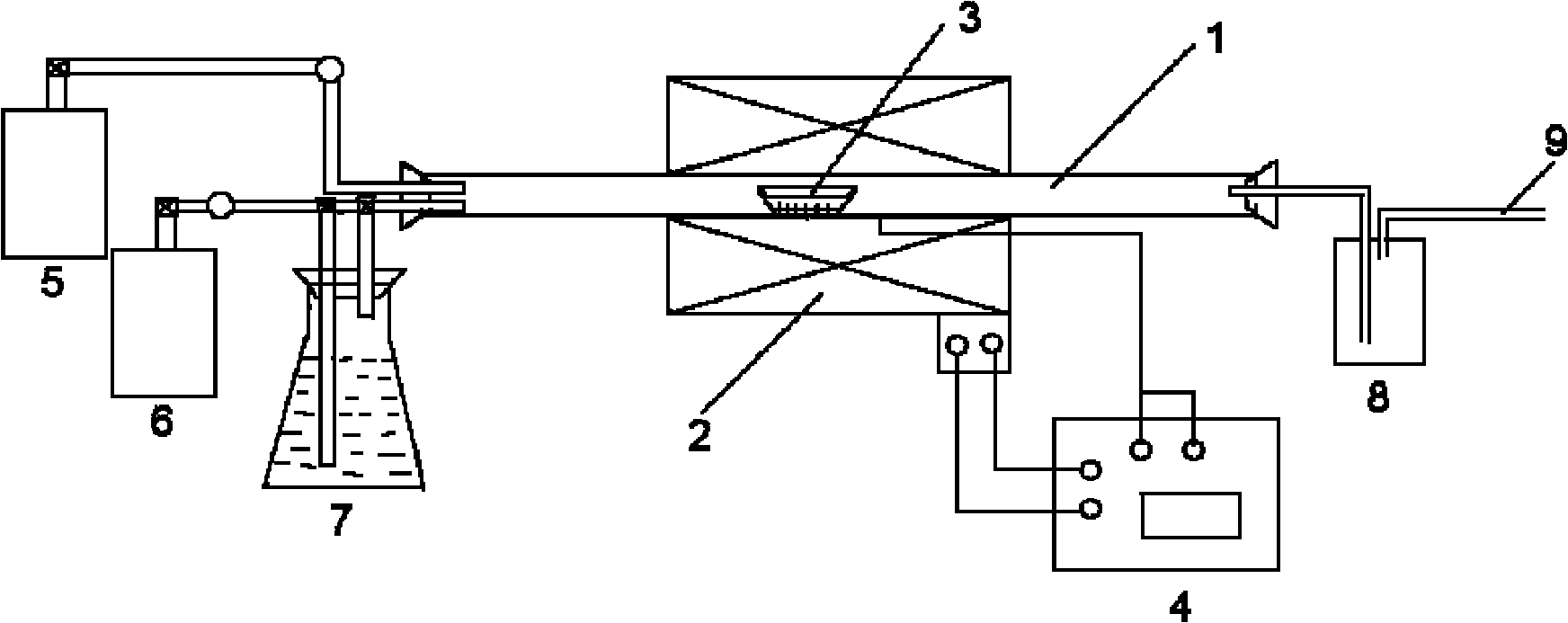

[0066] device attached figure 1 . Quartz tubes, quartz boats, and stainless steel sheets should be cleaned to keep them clean and prevent side effects due to pollution. The specific preparation process is as follows:

[0067] (1) Cut a commercially purchased stainless steel sheet into any size, soak it in hydrochloric acid for 10 minutes to remove surface impurities, and then wash it with ethanol for use.

[0068] (2) Put the above-mentioned treated stainless steel sheet into the quartz boat, and put them into the quartz tube reaction chamber together.

[0069] (3) Introduce argon gas (flow rate: 200ml / min) into the quartz tube reaction chamber described in step (2) for about 20 minutes to remove the air in the reaction tube, and then raise the temperature of the heating furnace to 1000°C.

[0070] (4) adjust the argon flow rate 1700ml / min in the step (3), and feed hydrogen and adjust its flow rate to 200ml / min, and carbon source dimethyl sulfide is brought into the reaction...

Embodiment 2

[0072] Front step is identical with step 1~3 in concrete embodiment 1, then the argon flow rate in adjusting step (4) is 1100ml / min, and feeds hydrogen and its flow rate is adjusted to 200ml / min, carbon source dimethyl The sulfide is brought into the reaction chamber by the hydrogen gas to react for 30 minutes, and the carbon nanotube composite material can be formed on the stainless steel sheet after the reaction is completed.

[0073] In specific implementation, the flow rate of argon gas, the flow rate of argon gas, the reaction temperature and the length of reaction time can be changed within a certain range, for example, the flow rate of argon gas is between 800~1800ml / min, the flow rate of hydrogen gas is between 100~300ml / min, and the reaction temperature is between The carbon nanotube composite material can be obtained between 950-1200°C and the reaction time is 15-45min.

Embodiment 3

[0075] The carbon nanotube composite material prepared in Example 1 is uniformly dispersed in paraffin wax or epoxy resin at a weight ratio of 1:5, and can be used as a microwave absorbing material. In the embodiment, when the carbon nanotube composite material / paraffin coating thickness is 2 mm, the maximum reflection attenuation reaches 29.58 dB at 14.80 GHz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com