Chitosan-based porous microsphere load palladium catalyst, preparation method and application thereof

A technology of porous microspheres and palladium catalysts, applied in the direction of organic chemical methods, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of large amount of organic solvent usage, complicated process, and low porosity, and achieve the goal of using organic solvents less, the preparation process is simple, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

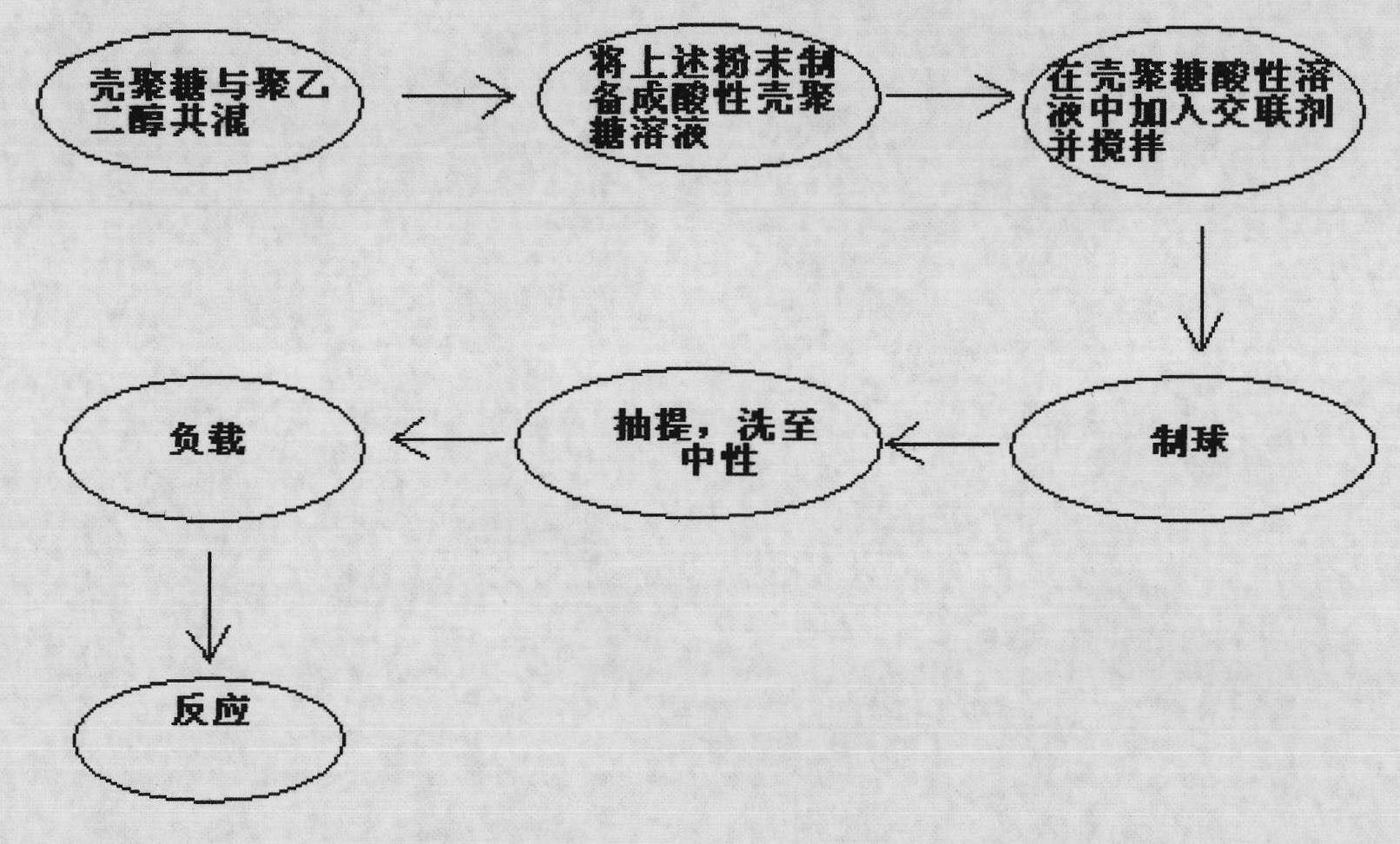

[0031] Such as figure 1 Shown, the preparation method of chitosan-based porous microsphere supported palladium catalyst of the present invention may further comprise the steps:

[0032] 1, the preparation of mixed solution: get pharmaceutical grade chitosan powder (molecular weight 100,000, degree of deacetylation is 95%) and polyethylene glycol (molecular weight 20,000) each 5g, be dissolved in 2% 100ml acetic acid solution, be made into Chitosan content (by weight) is a mixed solution of 1-10%; under high-speed stirring, add 5% glutaraldehyde aqueous solution dropwise to the solution, the degree of cross-linking is 0.3%, continue to stir for 2 hours to form a homogeneous solution, let it stand Degassing for 12h.

[0033] 2, the preparation of chitosan porous microsphere: above-mentioned mixed solution is dripped in the NaOH coagulation bath (concentration is 5%), and droplet precipitates gradually in coagulation bath and forms white Semi-IPN microsphere; After washing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com