Method for preparing nano structural spherical fluorescent powder

A nanostructure and phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of phosphor crystal grain size, luminous brightness attenuation, crystallization destruction, etc., achieve narrow particle size distribution, prevent high temperature agglomeration, and crystallization high quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) According to the chemical formula Y 2.94 Al 5 O 12 :Ce 0.06 The stoichiometric relationship in the raw material powder Al was weighed 2 O 3 , Y 2 O 3 and CeO 2 , put it into the ball mill tank of the ball mill, add polyvinyl alcohol binder, polyvinyl amide dispersant, n-butanol defoamer and distilled water, adjust the speed of the ball mill to 120 rpm, and disperse the ball for 4 hours to obtain a slurry ; Among them, the total amount of oxide powder in the slurry is 70wt%, the polyvinyl alcohol binder is 1wt%, the polyvinyl amide dispersant is 0.3wt%, the n-butanol defoamer is 1wt%, and the balance is distilled water ;

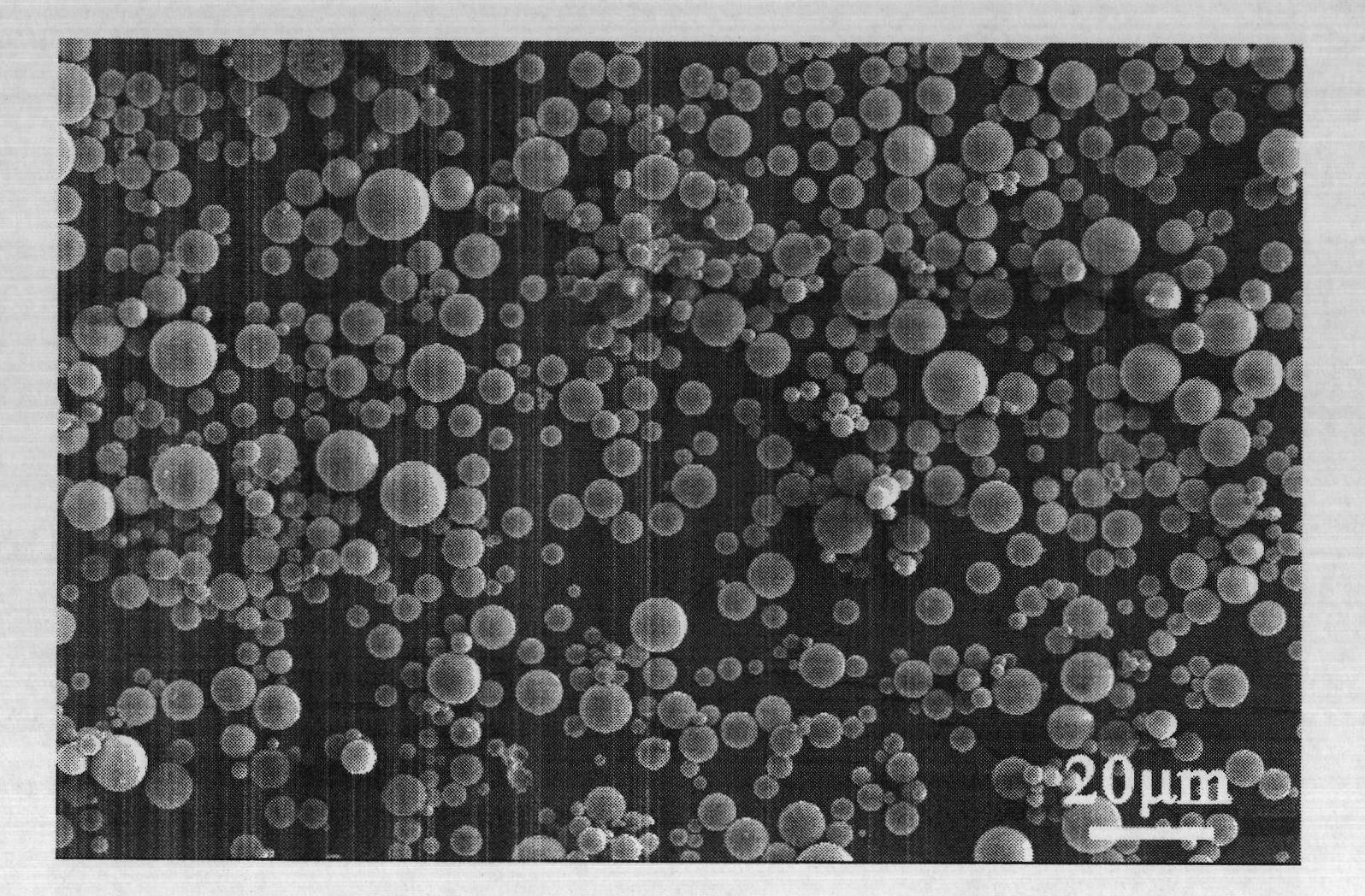

[0027] (2) adopt spray drier to carry out spray granulation, cross 200 mesh sieves, and collect granulated powder under the sieve;

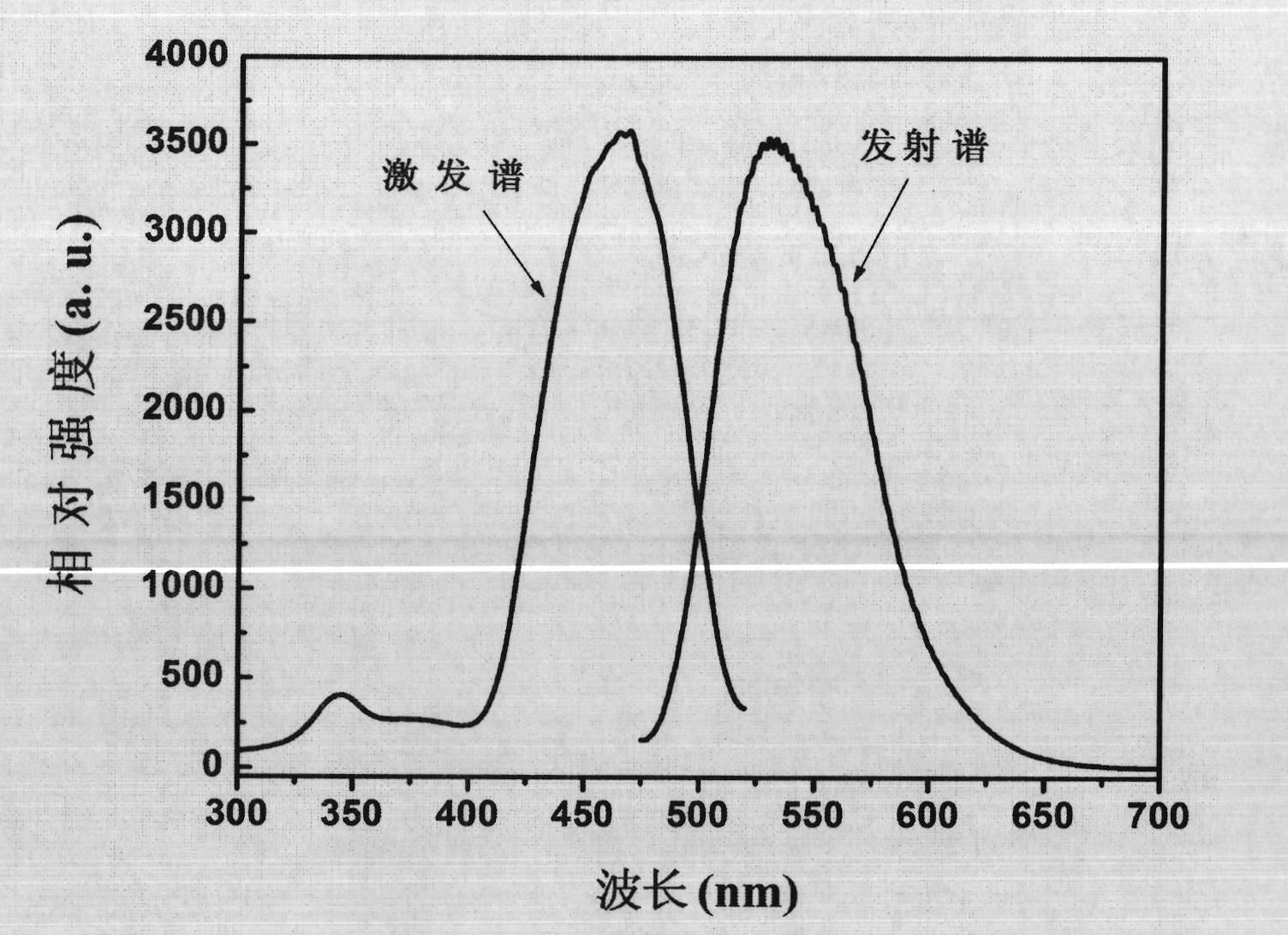

[0028] (3) the granulated powder obtained in step (2) is fed into the acetylene-oxygen flame at a rate of 20 g / min by a powder feeder, wherein the acetylene flow is 20 liters / min, and the oxygen flow is 15 li...

Embodiment 2

[0032] (1) According to the chemical formula Lu 0.99 AlO 3 :Ce 0.01 Weigh the raw powder Lu 2 O 3 , Al 2 O 3 and CeO 2 , put it into the ball mill tank of the ball mill, add polyvinyl alcohol binder, polyvinyl amide dispersant, n-butanol defoamer and distilled water, adjust the speed of the ball mill to 120 rpm, and disperse the ball for 8 hours to obtain a slurry ; Among them, the total amount of oxide powder in the slurry is 40wt%, the polyvinyl alcohol binder is 1.5wt%, the polyvinylamide dispersant is 0.2wt%, the n-butanol defoamer is 1.5wt%, and the balance is distilled water;

[0033] (2) adopt spray drier to carry out spray granulation, cross 200 mesh sieves, and collect granulated powder under the sieve;

[0034] (3) the granulated powder obtained in step (2) is fed into the acetylene-oxygen flame at a rate of 10 g / min by a powder feeder, wherein the acetylene flow is 20 liters / min, and the oxygen flow is 15 liters / min; The granular powder is heated and melted...

Embodiment 3

[0038] (1) According to the chemical formula Gd 2.94 Sc 2 Al 3 O 12 :Ce 0.06 The stoichiometric relationship in the raw material powder Gd is weighed 2 O 3 , Sc 2 O 3 , Al 2 O 3 and CeO 2 , put it into the ball mill tank of the ball mill, add polyethylene oxide binder, polyvinylamide dispersant, n-butanol defoamer and distilled water, adjust the speed of the ball mill to 120 rpm, and disperse the ball for 12 hours to obtain Slurry; wherein, the total amount of oxide powder in the slurry is 50wt%, the polyvinyl alcohol binder is 1wt%, the polyvinylamide dispersant is 0.2wt%, the n-butanol defoamer is 2wt%, and the balance is distilled water;

[0039] (2) adopt spray drier to carry out spray granulation, cross 200 mesh sieves, and collect granulated powder under the sieve;

[0040] (3) the granulated powder obtained in step (2) is fed into the acetylene-oxygen flame at a rate of 10 g / min by a powder feeder, wherein the acetylene flow is 20 liters / min, and the oxygen fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com