Polymer anion exchange membrane and preparation method thereof

An exchange membrane and polymer technology, applied in electrical components, circuits, battery electrodes, etc., can solve the problems of poor thermal stability and chemical stability of anion exchange membranes, decreased performance of anion exchange membranes, and no disclosure of mechanical performance data. Good thermal and chemical stability, good mechanical properties, simple results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

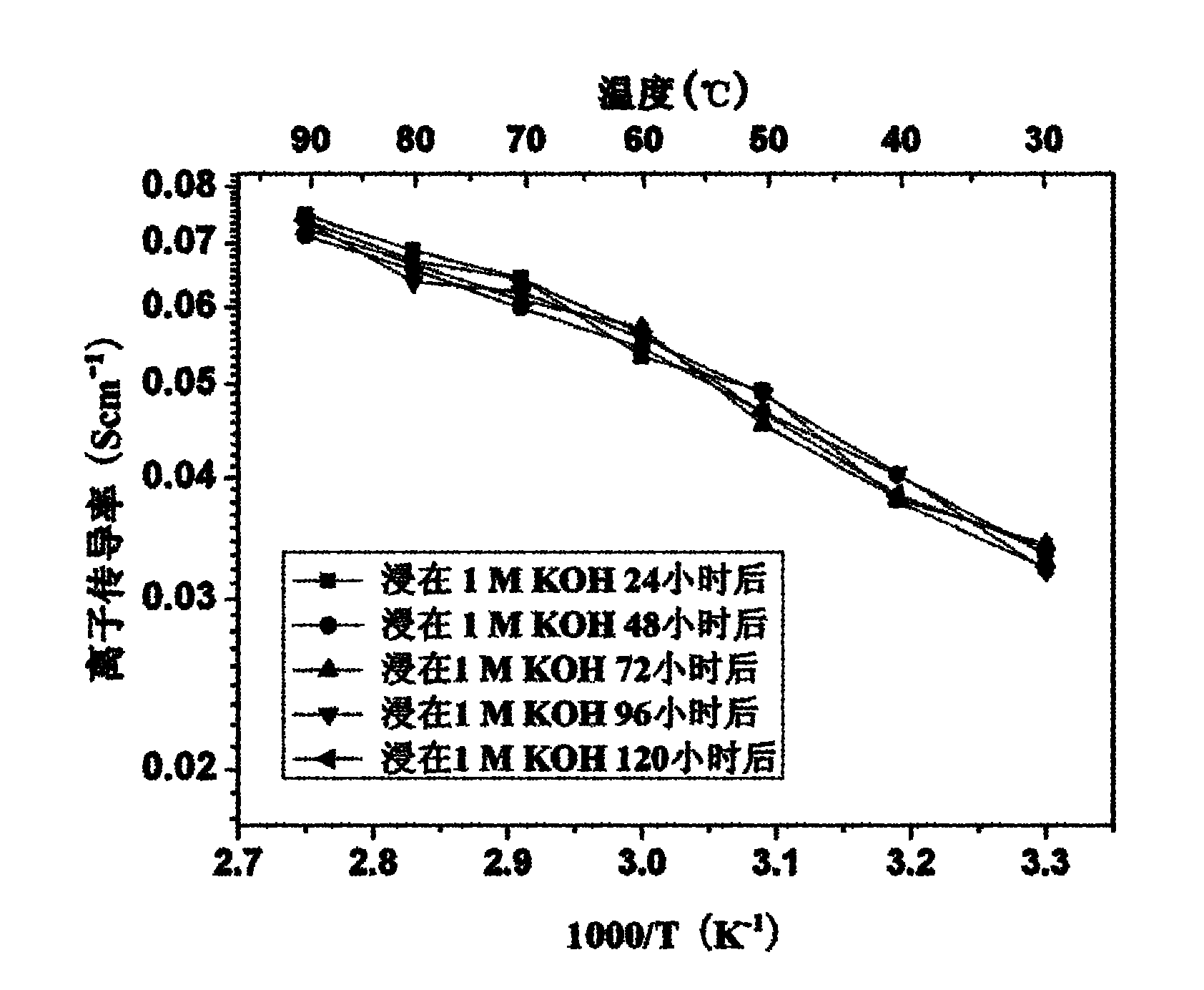

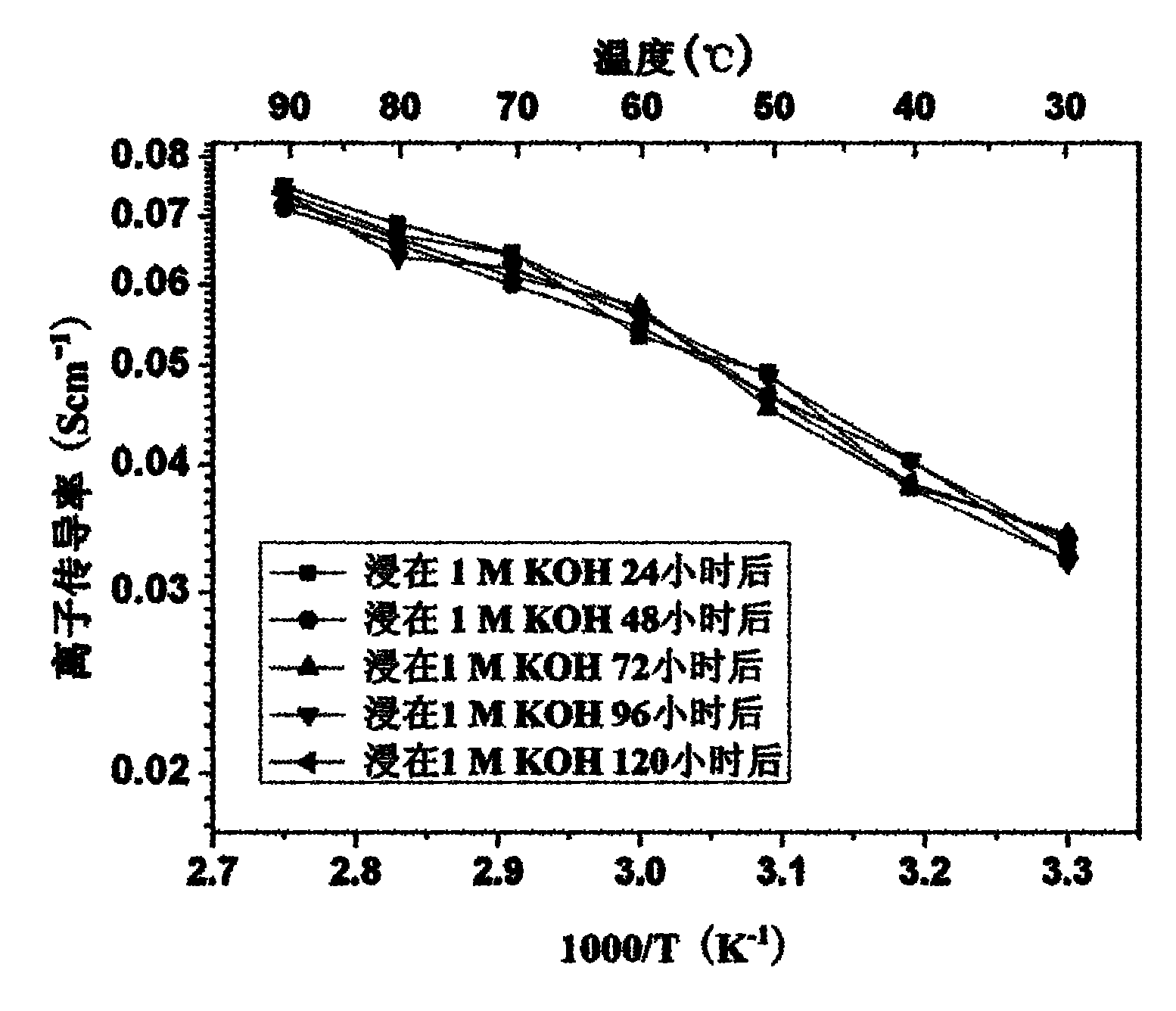

Embodiment 1

[0023] 0.20g (0.85mmol), 0.10g (0.96mmol) of styrene, 0.20g (3.73mmol) of acrylonitrile, 0.01g of benzoin ethyl ether, 0.02g of divinylbenzene, mix the solution evenly, apply it on the mold, and irradiate with ultraviolet light ( Wavelength 240nm-380nm) 30min, in-situ polymerization to form a film. The anion exchange membrane was then soaked in 1M KOH solution at 50°C for 24 hours to convert anions into OH - , the OH obtained in this example - The ion exchange capacity of the type anion exchange membrane is 1.47mmol / g, and the ion conductivity at room temperature is 3.13×10 -2 S cm -1 , the ionic conductivity at 90°C is 6.53×10 -2 S cm -1 . The tensile strength is 11.41Mpa, the Young's modulus is 439.9Mpa, and the elongation at break is 52.65%.

Embodiment 2

[0025] 0.20g (0.85mmol), 0.30g (5.60mmol) of acrylonitrile, 0.01g of benzoin ethyl ether, 0.02g of divinylbenzene, mix the solution evenly, apply it on the mold, irradiate with ultraviolet light (wavelength 240nm-380nm) for 30min, in situ Polymerize into film. Then soak the anion exchange membrane in 5M KOH solution at 60°C for 24 hours to convert anions into OH - , the OH obtained in this example - The ion exchange capacity of the type anion exchange membrane is 1.52mmol / g, and the ion conductivity at room temperature is 3.60×10 -2 S cm -1 , the ionic conductivity at 90°C is 7.53×10 -2 S cm -1 . The tensile strength is 10.23Mpa, the Young's modulus is 521.34Mpa, and the elongation at break is 55.34%.

Embodiment 3

[0027] 0.20g (0.87mmol), 0.30g (5.60mmol) of acrylonitrile, 0.01g of benzoin ethyl ether, 0.02g of azobisisobutyronitrile, mix the solution evenly, apply it on the mold, polymerize at 75°C for 6 hours, and in situ Polymerize into film. The anion exchange membrane was then soaked in 10M KOH solution at 60°C to convert anions into OH - , the OH obtained in this example - The ion exchange capacity of the type anion exchange membrane is 1.53mmol / g, and the ion conductivity at room temperature is 3.6×10 -2 S cm -1 , the ionic conductivity at 90°C is 6.26×10 -2 S cm -1 . The tensile strength is 10.23Mpa, the Young's modulus is 521.34Mpa, and the elongation at break is 55.34%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com