Method for preparing cathode electrode material of nanometer sheet microspheric lithium ion cell

A lithium-ion battery, cathode electrode technology, applied in battery electrodes, nanotechnology, circuits, etc., can solve the problems of large specific surface area of nanoparticles or nanospheres, reduced material energy density, and reduced material discharge capacity, etc. The effect of reducing interface resistance and low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

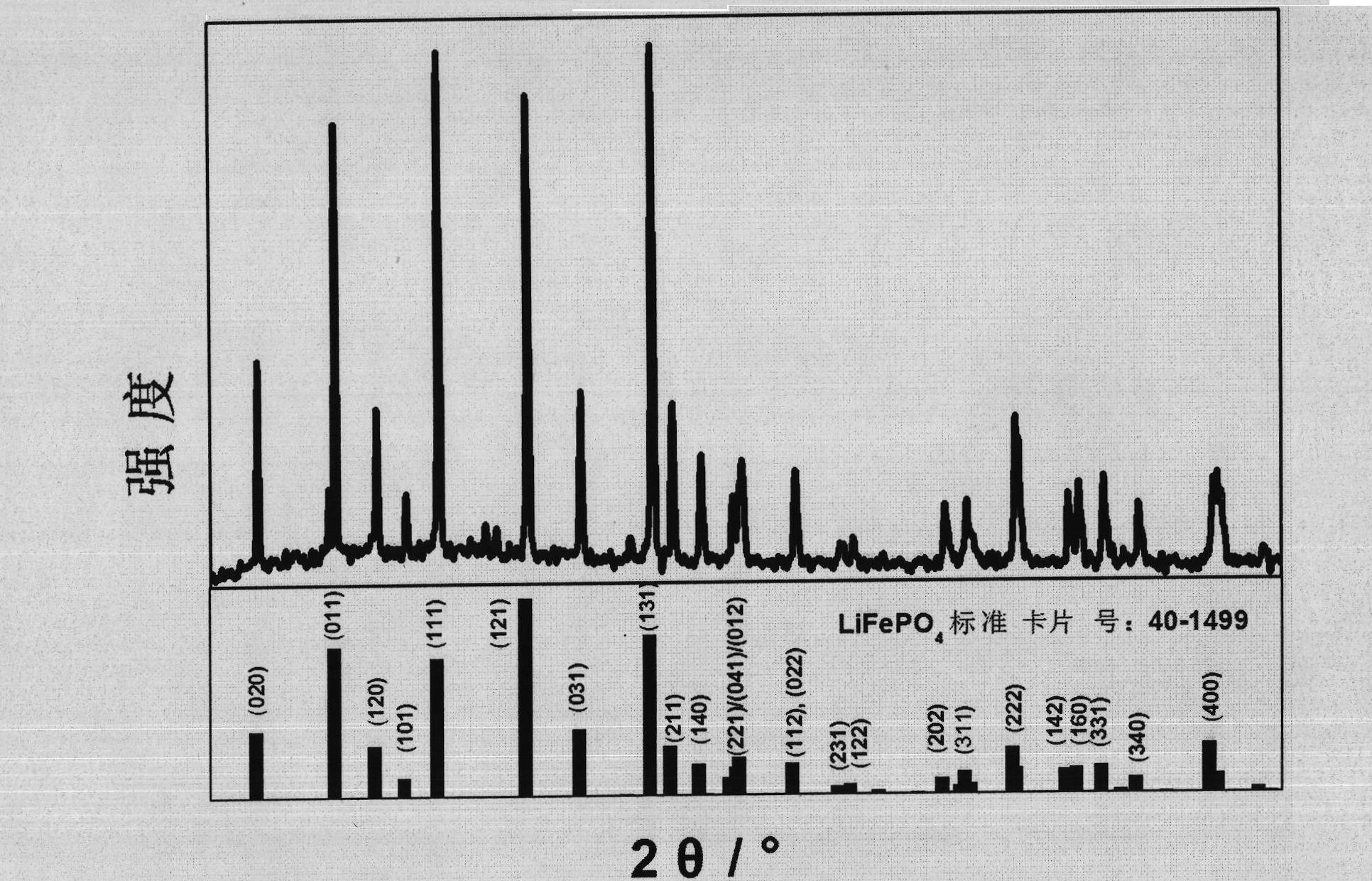

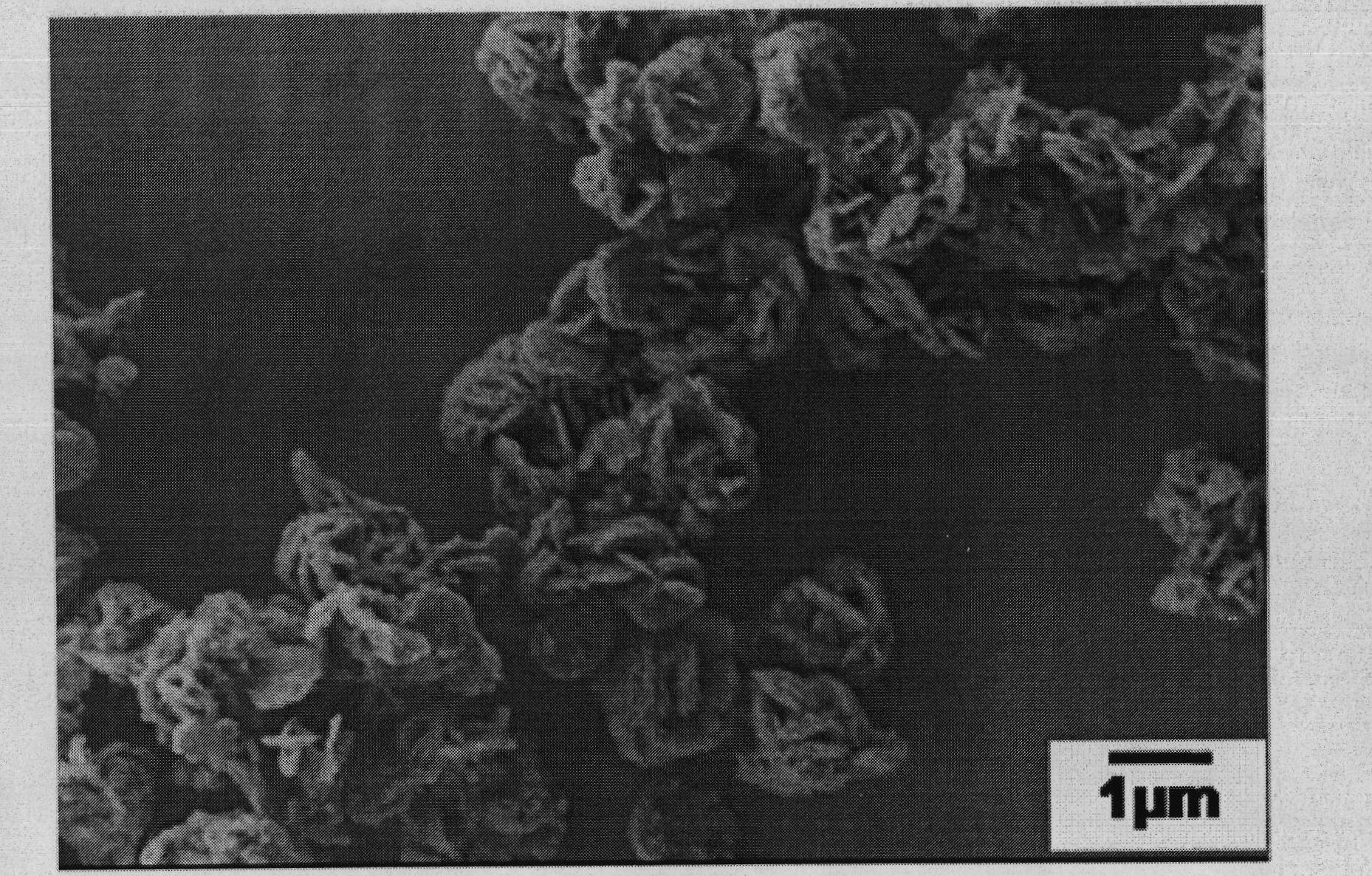

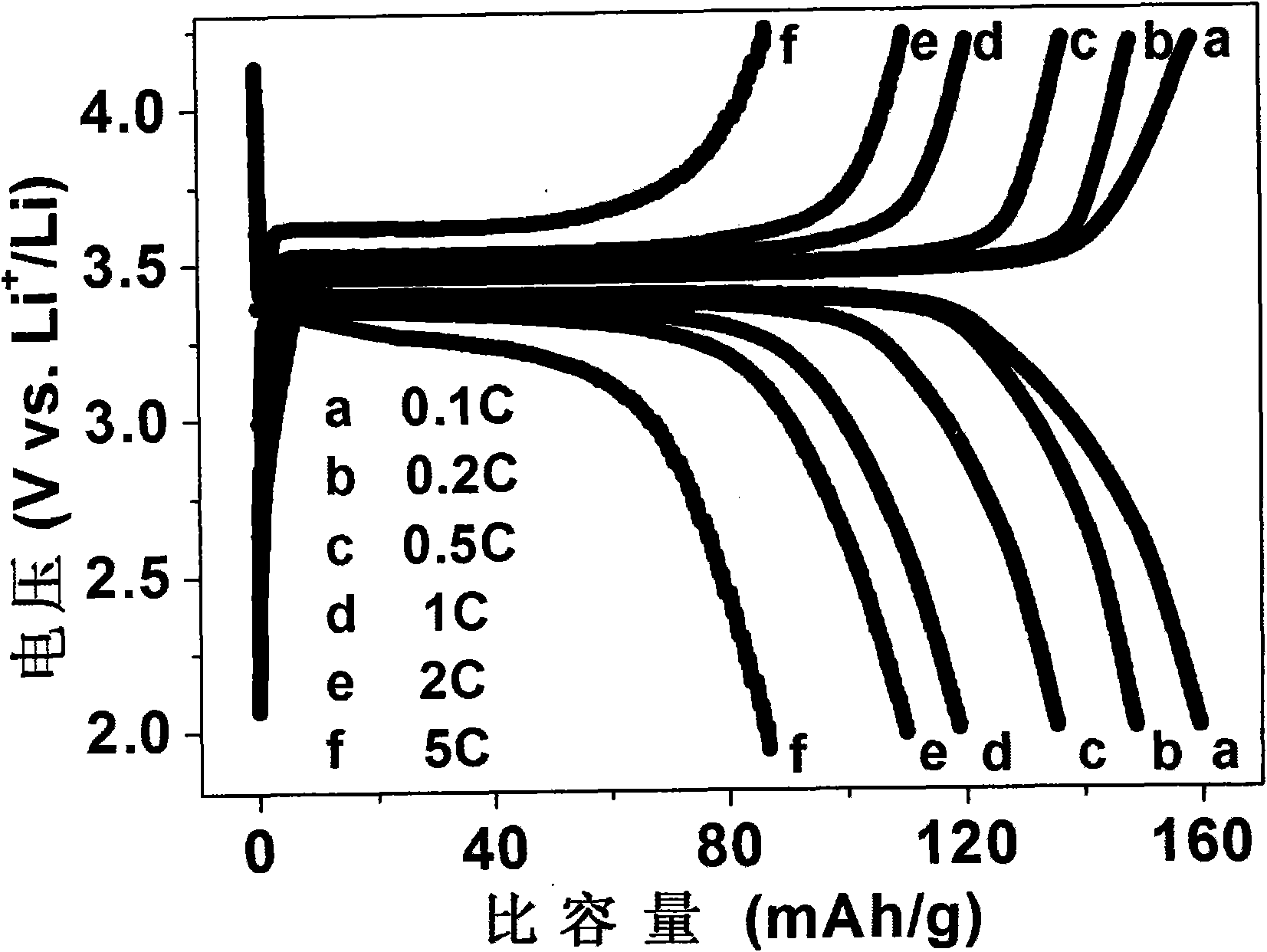

[0017] The invention provides a method for preparing a cathode electrode material of a nanosheet microsphere lithium ion battery. The cathode electrode material of the nanosheet microsphere lithium ion battery is carbon-coated olivine-type LiFePO 4 Hierarchical structure nanosheet microspheres, the present invention will be further described below in conjunction with the accompanying drawings and examples. Concrete preparation steps include:

[0018] (1) Preparation process of iron phosphate nanosheet microspheres: firstly, 22.3g FePO 4 4H 2 O, 6.7g (NH 4 ) 2 SO 3 ·H 2 O and 2mL of ammonia water with a concentration of 25wt% were fully mixed in 100mL of deionized water, then refluxed and stirred at 60°C for 5-8 hours, repeatedly washed with deionized water by suction filtration, and dried at 50°C for 8-12 hours to obtain the product (NH 4 ) x FePO 4 (04 Nanocrystals grow into nanodiscs, and hydrogen bonds formed by ammonium radicals, water molecules and phosphate radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com