Negative electrode material for non-aqueous electrolyte secondary batteries, manufacturing method therefor, and lithium-ion secondary batteries

一种非水电解质、二次电池的技术,应用在二次电池、电池电极、用于材料和表面科学的纳米技术等方向,能够解决降低气体对策、不够充分等问题,达到降低起火和破裂、制造方法简单、安全性和循环特性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

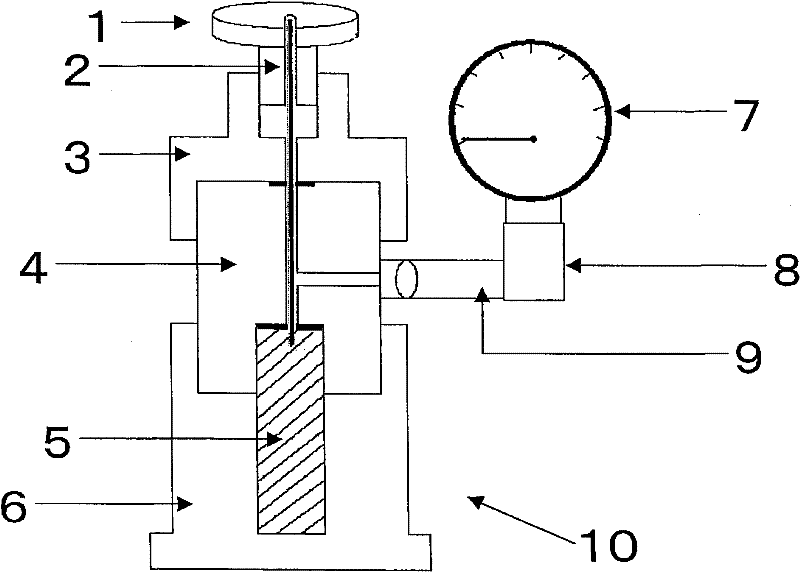

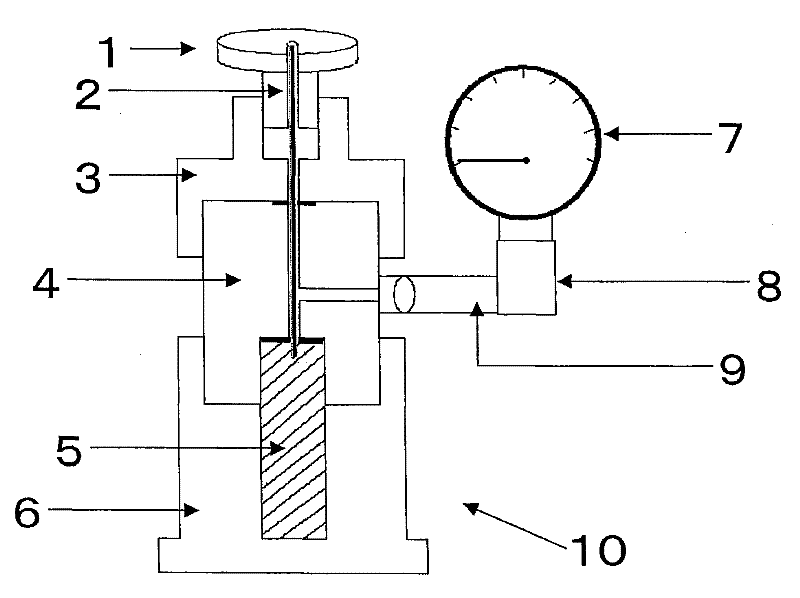

Image

Examples

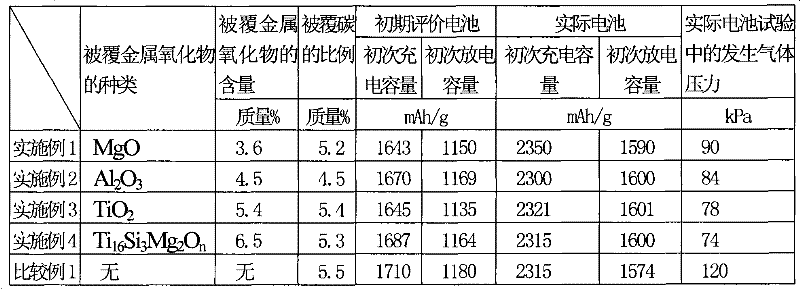

Embodiment 1

[0094] Prepare a powder obtained by dispersing silicon nanoparticles in silicon oxide, the powder has an average particle diameter of 5 μm and a BET specific surface area of 3.5 m 2 / g. Then, this powder was dried at 120° C. for 6 hours in an electric drying oven blown with nitrogen gas to prepare raw material powder [A].

[0095] Then, at room temperature, first prepare a solution obtained by dissolving 30 g of magnesium ethoxide (Magnesium diethoxide) powder in 400 g of dehydrated ethanol, and then slowly put 100 g of the previously dried raw material powder [A] into the solution , to produce a slurry. In order to prevent moisture in the atmosphere from diffusing into the beaker, these operations were performed while blowing dry nitrogen gas into the beaker.

[0096] Then, 5 grams (g) of pure water was added dropwise over 10 minutes while stirring, and stirring was continued for 3 hours in this state. Thereafter, the supernatant liquid was discarded, and filtered under ...

Embodiment 2

[0120] Into a 2-liter beaker in which 300 g of dehydrated isopropyl alcohol (IPA) had been put, 100 g of the raw material powder [A] used in Example 1 was slowly put in at room temperature to prepare a slurry.

[0121] Then, a mixed solution of 100 g of dehydrated isopropanol and 50 g of aluminum tri-sec-butoxide (Aluminium tri-sec-butoxide) prepared in a separate container was added and stirred. In order to prevent moisture in the atmosphere from diffusing into the beaker, these operations were performed while blowing dry nitrogen gas into the beaker.

[0122] Here, 10 g of pure water was added dropwise over 10 minutes while stirring, and then stirring was continued for 3 hours in this state. Thereafter, the supernatant liquid was discarded, and filtered under reduced pressure using a suction filter to obtain a cake, which was then dried at 100° C. for 3 hours under reduced pressure. The resulting powder weighed 105 grams. In addition, as a result of analyzing this powder w...

Embodiment 3

[0127] Into a 2-liter beaker in which 300 g of dehydrated isopropyl alcohol (IPA) had been put, 100 g of the raw material powder [A] used in Example 1 was slowly put in at room temperature to prepare a slurry.

[0128] Then, a mixed solution of 100 g of dehydrated isopropanol and 50 g of titanium tetraisopropane oxide (TTIP) prepared in a separate container was added and stirred. In order to prevent moisture in the atmosphere from diffusing into the beaker, these operations were performed while blowing dry nitrogen gas into the beaker.

[0129] Here, 10 g of pure water was added dropwise over 10 minutes while stirring, and then stirring was continued for 3 hours in this state. Thereafter, the supernatant liquid was discarded, and filtered under reduced pressure using a suction filter to obtain a cake, which was then dried at 100° C. for 3 hours under reduced pressure. The powder obtained was 106 g. In addition, as a result of analyzing this powder with an inductively coupled...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com