Method for preparing fudosteine molecularly imprinted polymer

A technology of molecular imprinting and polymers, which is applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of difficult degradation, residue, long metabolism time, etc., to improve detection sensitivity and The effect of detection efficiency and large promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Mix fudosteine 0.5mmol, MAA1mmol, EGDMA10mmol, pour into 2.5ml of methanol and toluene mixture, the ratio of the two is 1:1.4, after standing at room temperature for half an hour, add 20mg of initiator AIBN.

[0019] Put the above mixture into a reaction bottle, and degas it by ultrasonic for 10 min. The degassed system was purged with nitrogen for 5 minutes to remove oxygen. Quickly seal under nitrogen protection. 55 ℃ water bath insulation reaction for 14h. The reaction product is obtained.

[0020] After the reaction, the prepared molecularly imprinted polymer was ground and passed through a sample sieve. After settling with acetone three times, the obtained polymer was dried, and the particle diameter of the polymer was between 30-60 um. Template molecules were removed by Soxhlet extraction for 12 h. The extraction reagent is 180mL methanol containing 10% acetic acid. Residual acetic acid was eluted with methanol. The molecularly imprinted polymer from whic...

Embodiment 2

[0022] Mix fudosteine 0.5mmol, MAA 2mmol, EGDMA 10mmol, pour into porogen methanol, toluene mixture 2.5mL, the ratio of the two is 1:1.4, after standing at room temperature for 1h, add initiator AIBN 20mg. Put the above mixture into a reaction bottle and degas it by ultrasonic for 5 min. The degassed system was purged with nitrogen for 5 minutes to remove oxygen. Quickly seal under nitrogen protection. 60 ℃ water bath insulation reaction for 24h.

[0023] After the reaction, the prepared molecularly imprinted polymer was ground, and the sample was sieved with a standard sieve. After the polymer was settled 3 times with acetone, the obtained polymer was dried. Template molecules were removed by Soxhlet extraction for 20 h. The extraction reagent is 180mL methanol containing 20% acetic acid. Residual acetic acid was eluted 1-2 times with methanol. Finally, the molecularly imprinted polymer from which template molecules were removed was vacuum-dried overnight at 60° C. ...

Embodiment 3

[0025] Mix 0.5mmol of fudosteine, 4mol of MAA, and 10mmol of EGDMA, pour into 2.5mL of methanol and toluene mixture, the ratio of the two is 1:1.4, and after standing at room temperature for 1h, add 20mg of initiator AIBN. Put the above mixture into a reaction bottle, and degas it by ultrasonic for 10 min. The degassed system was purged with nitrogen for 10 minutes to remove oxygen. Seal quickly under the protection of nitrogen. 55 ℃ water insulation reaction for 20h.

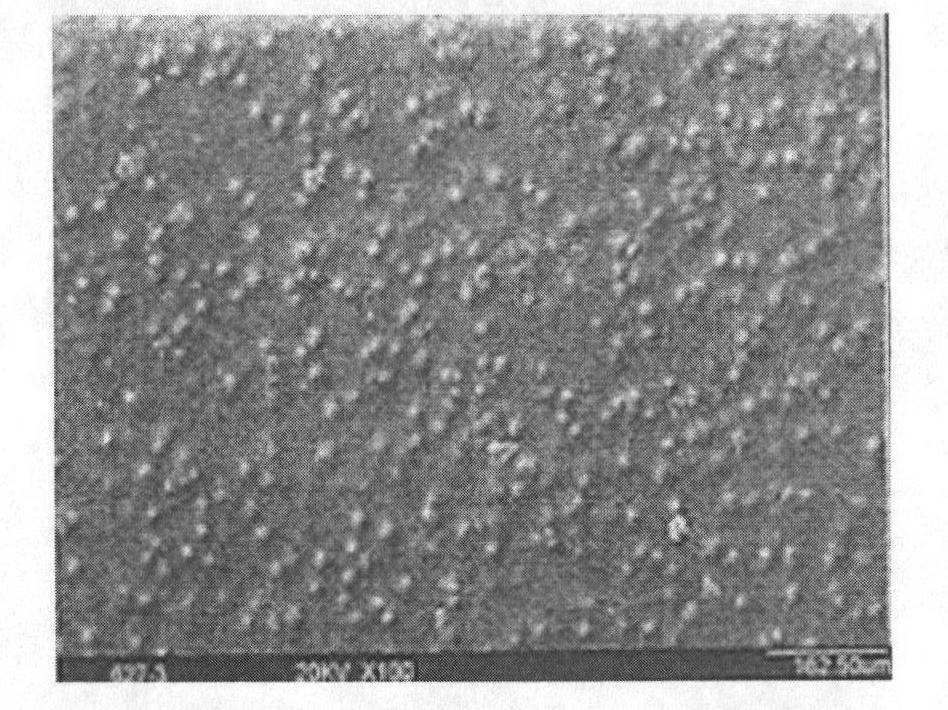

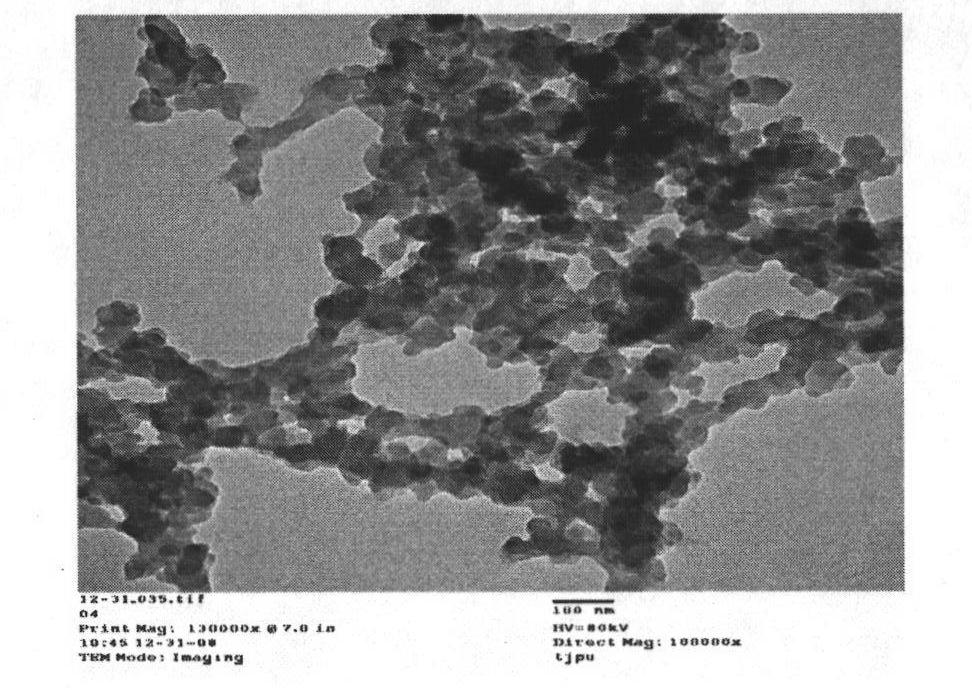

[0026] After the reaction, the prepared molecularly imprinted polymer was ground and passed through a sample sieve. After settling through acetone 3 times, the resulting polymer was dried. The template molecules were removed by Soxhlet extraction for 36 h. The extraction reagent is 180ml methanol containing 30% acetic acid. Finally, the molecularly imprinted polymer from which template molecules were removed was dried overnight at 60° C. to obtain fudosteine molecularly imprinted polymer. Electron micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com