Metal-semiconductor electrode structure and preparation method thereof

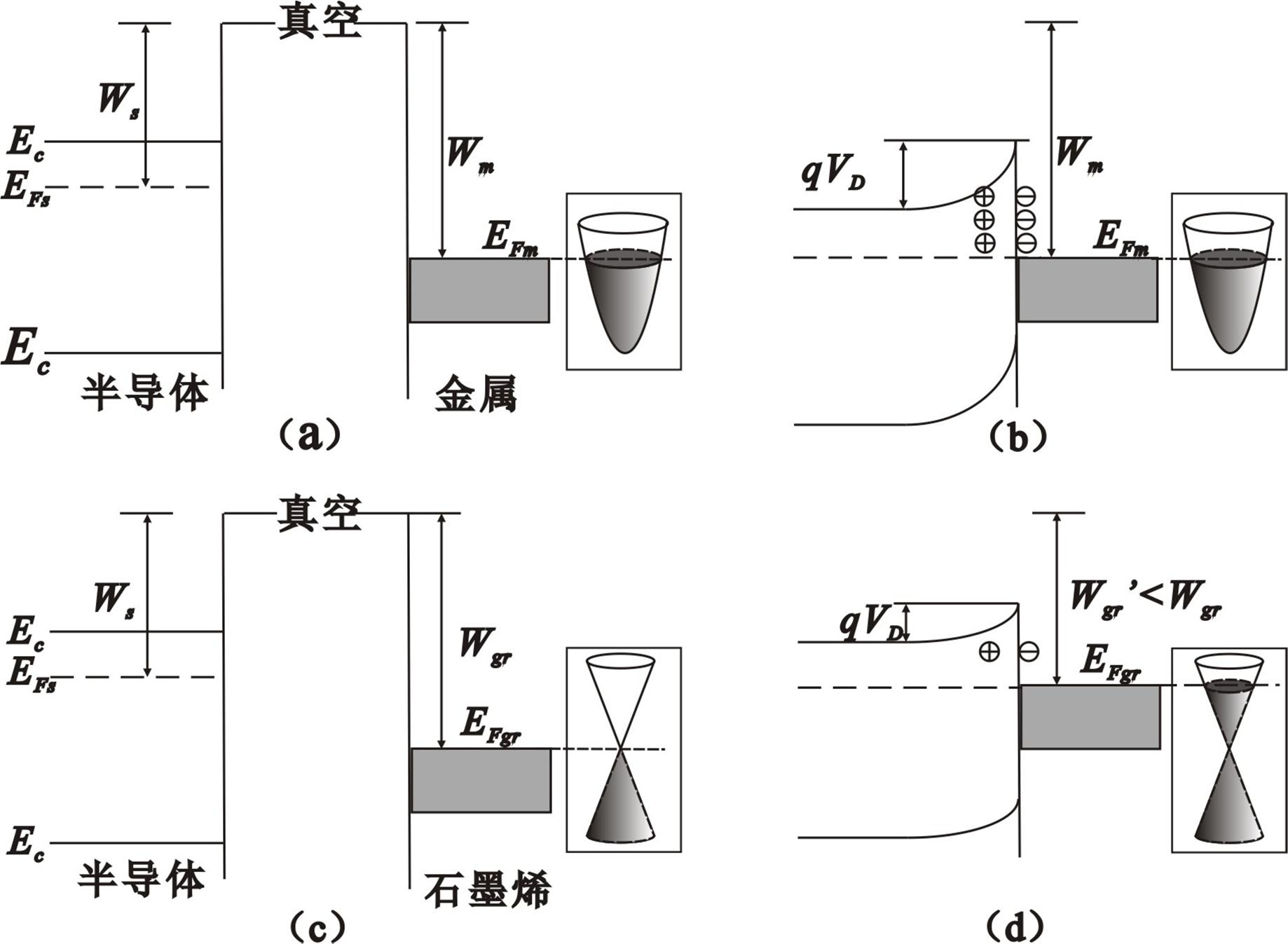

An electrode structure and metal electrode technology, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, circuits, etc., can solve the problems of annealing and other processes that are inevitable, contact metals cannot be found, and the preparation process is complicated, so as to improve the energy band state, Low cost and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1 is described by taking an intrinsic GaN crystal as an example of a semiconductor layer.

[0025] Step 11, refer to attached Figure 2A, Graphene preparation: the graphene film 110 is prepared on the surface of the growth substrate 100 by chemical vapor deposition. The specific implementation of the chemical vapor deposition method belongs to the known technology and will not be described in detail here. This step needs to provide a separate growth substrate 100 for the chemical vapor substrate process. The chemical vapor deposition process can form a graphene film on the surface of the growth substrate 100, and this process has very broad requirements on the material of the growth substrate 100. Many common substrate materials, such as single crystal silicon, sapphire, glass and even metal Substrates can meet the requirements. The graphene film 110 can also be grown by wet chemical method. The graphene film 110 is graphene without p-type or n-type doping...

Embodiment 2

[0035] Embodiment 2: It is described by taking a P-type GaN crystal as an example of a semiconductor layer.

[0036] Step 21, graphene preparation: the graphite redox method is used to prepare the graphene powder material. The specific implementation of the graphite reduction method belongs to the known technology and will not be described in detail here.

[0037] Step 22, cleaning the p-type GaN crystal: cleaning the surface with organic solvents such as acetone and alcohol.

[0038] Step 23, covering the p-type GaN crystal with a graphene layer: spin coating the graphene powder material on the p-type GaN crystal.

[0039] Step 24, evaporating metal: using a vacuum evaporation method to cover the conductive metal layer on the graphene layer.

[0040] Step 25, forming an etching stopper layer on the surface of the metal layer.

[0041] Step 26, using inductively coupled plasma (ICP) to etch the metal layer and the graphene layer until the p-type GaN crystal stops, forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com