Processes for preparing and purifying quartz sand and quartz powder and products thereof

A technology of quartz sand and quartz powder, which is applied in the preparation and purification process of quartz sand and quartz powder and its products, can solve the problems that chemical liquids corrode equipment, affect the service life of equipment, and affect purity requirements, etc. High efficiency of impurity technology, high effect of impurity removal, and high product quality and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

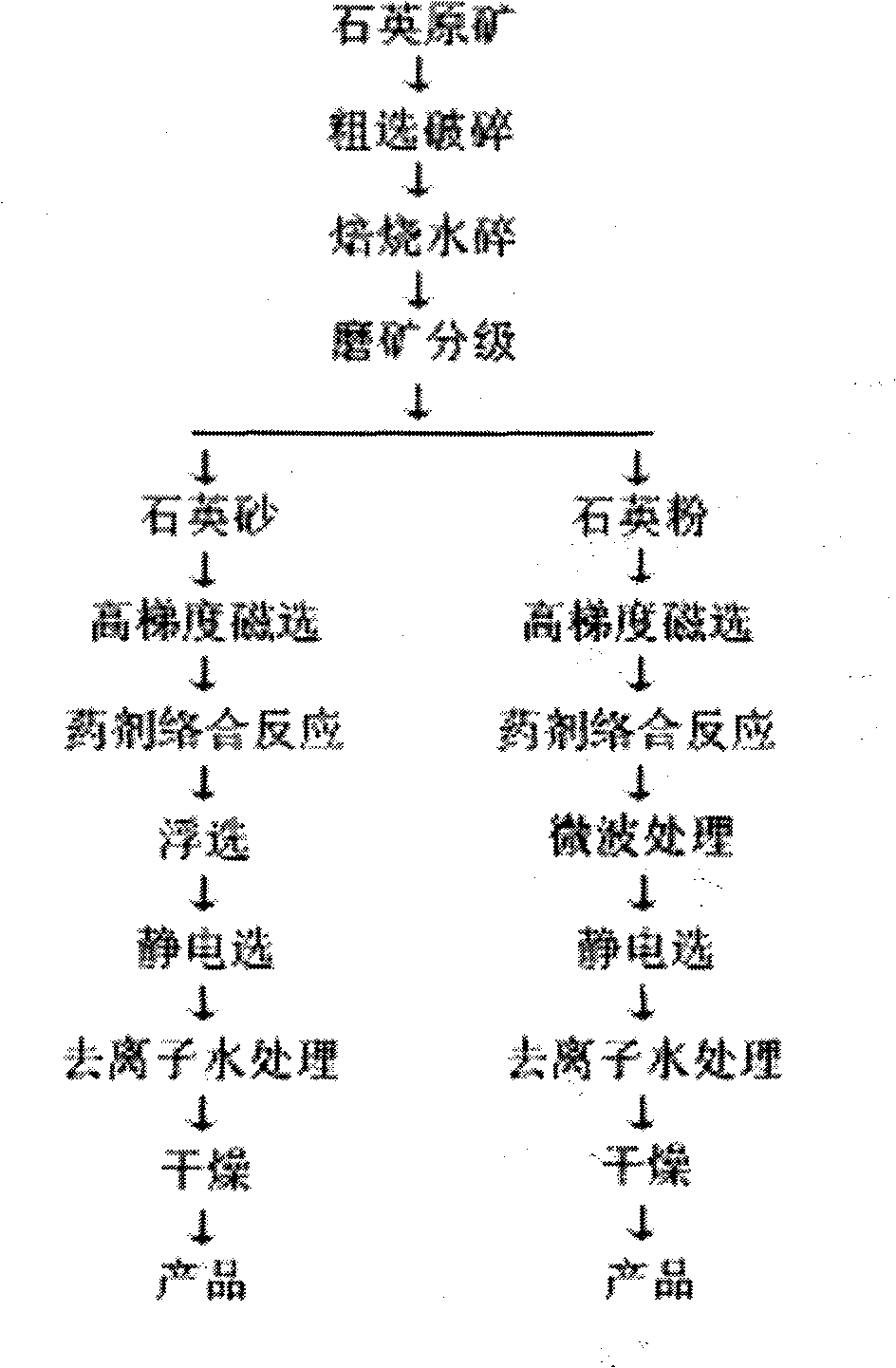

[0039]The preparation and purification process of quartz sand in the present invention is as follows: After the raw quartz ore is roughly selected, it is crushed to 0.5-1cm granular quartz, placed in a roasting kiln for firing, and roasted at a temperature of 700°C-800°C for 3-4 hours According to the total amount of 1 ton of quartz sand and 2 tons of water, add 5%--8% sodium hydroxide, place the quartz particles after high-temperature roasting in the aqueous solution containing sodium hydroxide, and make the quartz particles after crystal temperature roasting In the aqueous solution containing sodium hydroxide, the bursting is realized by cooling, and the bubbles, water lines and impurities in the inclusions inside the quartz ore are removed, the water lines are naturally cracked, and the crushed vein quartz particles are ground in a mill, passed Classify to obtain 100-320 mesh quartz sand and 800-5000 mesh quartz powder; then use magnetic separation equipment with a magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com