Yellow-green light strongly excitable molybdate red fluorescent material and preparation method thereof

A technology for red fluorescent and luminescent materials, applied in luminescent materials, chemical instruments and methods, sustainable architecture, etc., can solve the problems of chip wavelength drift and peak deviation, meet the requirements of light color quality, and is conducive to industrial production and preparation simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

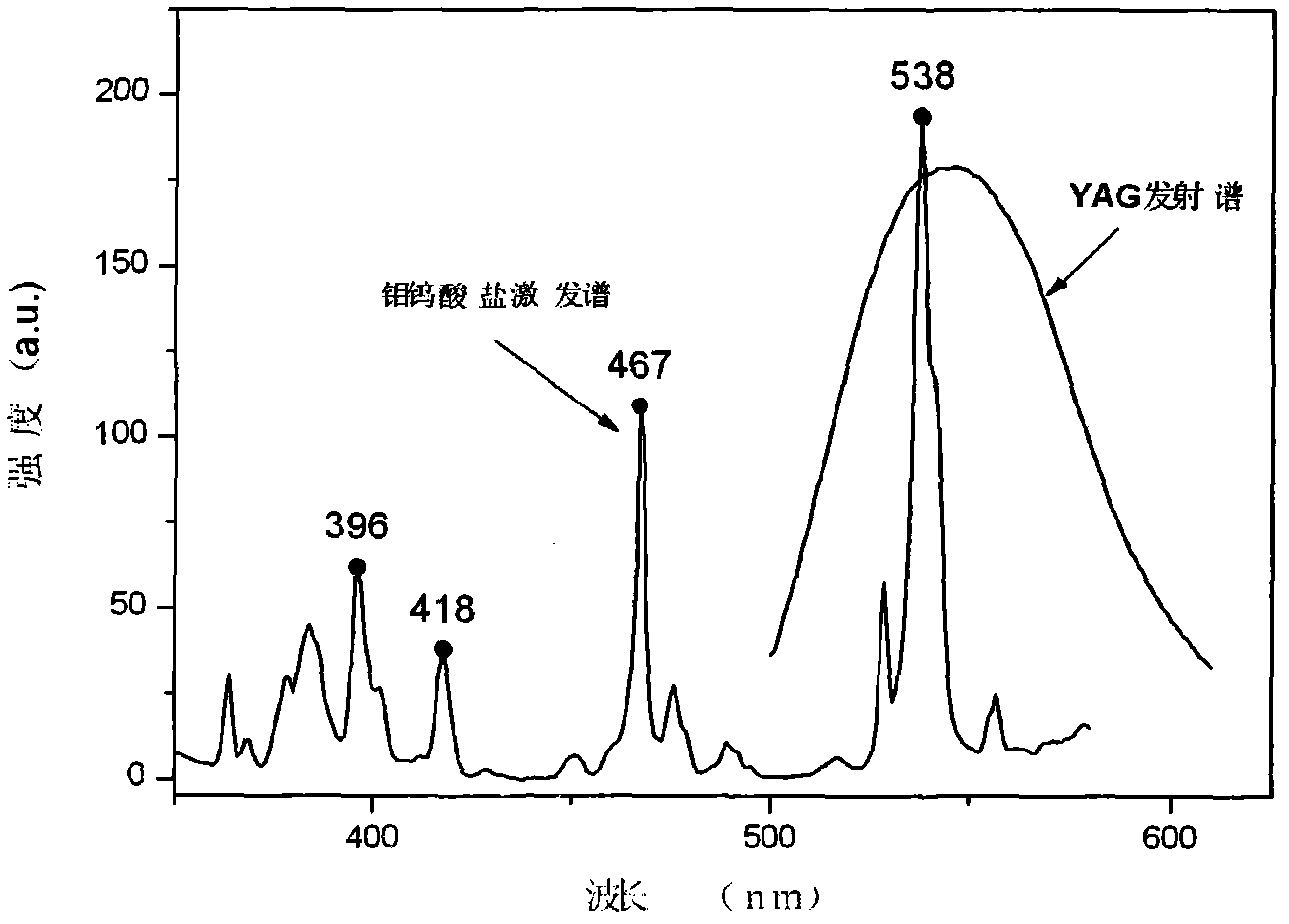

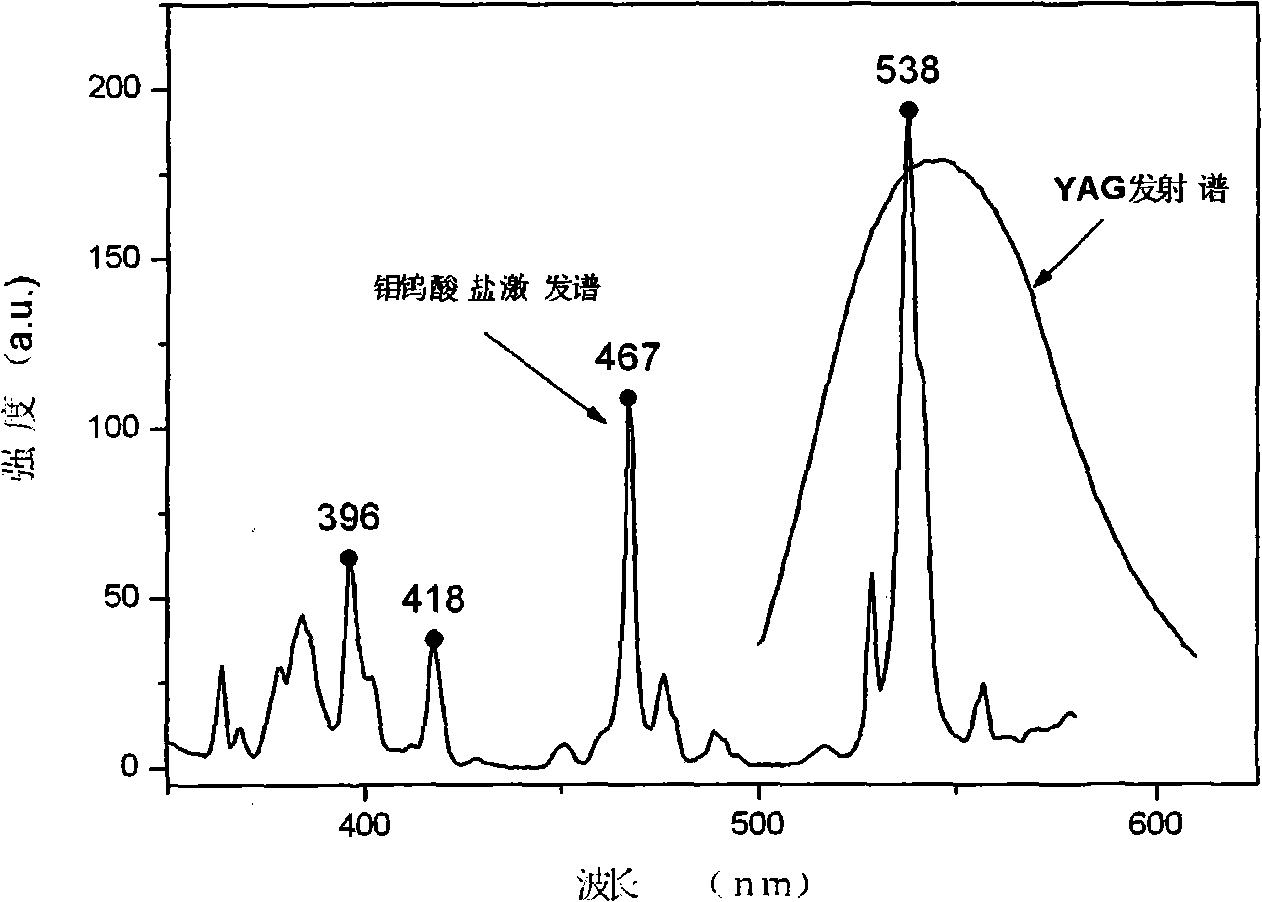

[0027] Press LiY 0.5 Eu 0.5 (MoO 4 ) 2 Stoichiometric ratio weighed 1.1153gEu(NO 3 ) 3 ·6H 2 O, 0.9673gY (NO 3 ) 3 ·6H 2 O, dissolved in 15ml deionized water, then added 5.2799g citric acid as a chelating agent, 1.7767g (NH 4 ) 6 Mo 7 o 24 4H 2 O with 0.1904gLi 2 CO 3 Added to the solution, stirred to obtain a transparent solution. Heat the solution to 100°C under stirring, continue to stir and keep it warm for 1 hour to obtain a viscous object, keep it in a drying oven at 120°C for 24 hours to obtain a light yellow xerogel, grind it evenly in an agate mortar, and then transfer it to corundum The crucible was heated in a muffle furnace to 750°C for 6 hours, and after it was cooled to room temperature, it was taken out and then ground slightly to obtain a fine powder. X-ray diffraction analysis proves that the sample has a scheelite-type tetragonal crystal structure. The excitation and emission of the sample are shown in Figure 1. The main emission peak is loca...

Embodiment 2

[0029] Press NaY 0.5 Eu 0.5 (MoO 4 ) 2 Stoichiometric ratio weighed 0.2655g Na 2 CO 3 , 0.44g Eu 2 o 3 , 0.2823gY 2 o 3 , 1.4467 g MoO 3 Put it in an agate mortar and add absolute ethanol to grind for 0.5 hours, dry it at 70°C, transfer it into a corundum crucible, put it in a muffle furnace and heat it to 750°C for 6 hours. After the temperature dropped to room temperature, the sample was ground into powder in an agate mortar. The X-ray diffraction results of the obtained sample show that the powder has a scheelite-type tetragonal crystal structure, and the excitation spectrum emitted at 616nm is monitored, and the highest excitation intensity is located at around 538nm.

Embodiment 3

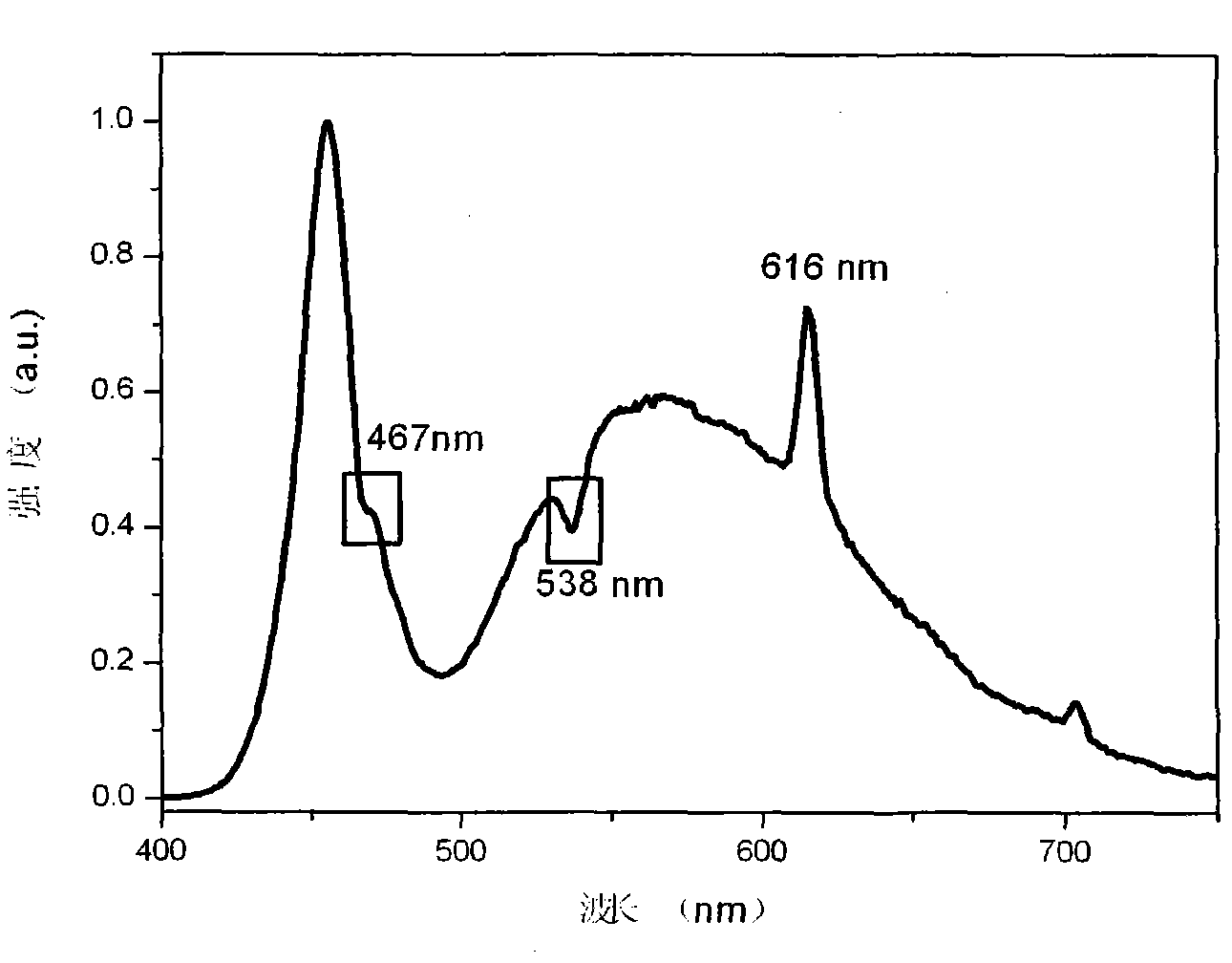

[0031] The sample powder gained in embodiment 1 is mixed with commercial YAG:Ce 3+ In a layered form, the commercial LED blue chip is covered and assembled into an LED device, wherein YAG:Ce 3+ The layer is next to the LED chip, and the sample powder layer is covered in YAG:Ce 3+ Above, the ratio of the thickness of the two layers is about 1:1. The spectrum diagram of the packaged LED device driven by a forward current of 0.02 ampere is shown in FIG. 2 . The peak emission at around 460nm in the spectrogram belongs to the chip emission, and the broad-spectrum emission with the main emission peak at 550nm belongs to YAG:Ce 3+ launch, but in YAG:Ce 3+ There is an obvious depression at about 538nm of the emission, and this peak position just corresponds to the strongest excitation peak at 538nm of the sample obtained in Example 1. In addition, there is an obvious emission peak at 616nm in the device spectrum. The changes in these two aspects It also just proves that YAG:Ce 3+...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com