Preparation method of low-cost selective coating for solar thermal collector

A solar heat collector and selective technology, applied in the field of solar energy utilization materials, can solve the problems of difficult target production, low purity of cuprous oxide, and difficulty in preparing thin films with a certain thickness, and achieve broad environmental protection application potential and good spectrum Selective features, the effect of easy large area of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Sodium hydroxide and sodium hypochlorite are added into deionized water according to the molar ratio of 3:1, after fully stirring, a uniformly mixed solution is obtained, and put into a constant temperature water bath of 80°C;

[0023] (2) Ammonium persulfate, ammonium chloride, and deionized water are mixed according to a molar ratio of 1:2:66, and after fully stirring, a uniform mixed solution is obtained;

[0024] (3) Cut the copper sheet into a suitable size and put it into the solution of step (2) to react for 1 minute, then dry it at 100°C and put it into the solution of step (1) to react for 5 minutes, then take it out and go through deionization After repeated washing with water, it is dried in the air at 100° C. to obtain the selective coating for solar heat collectors in the present invention.

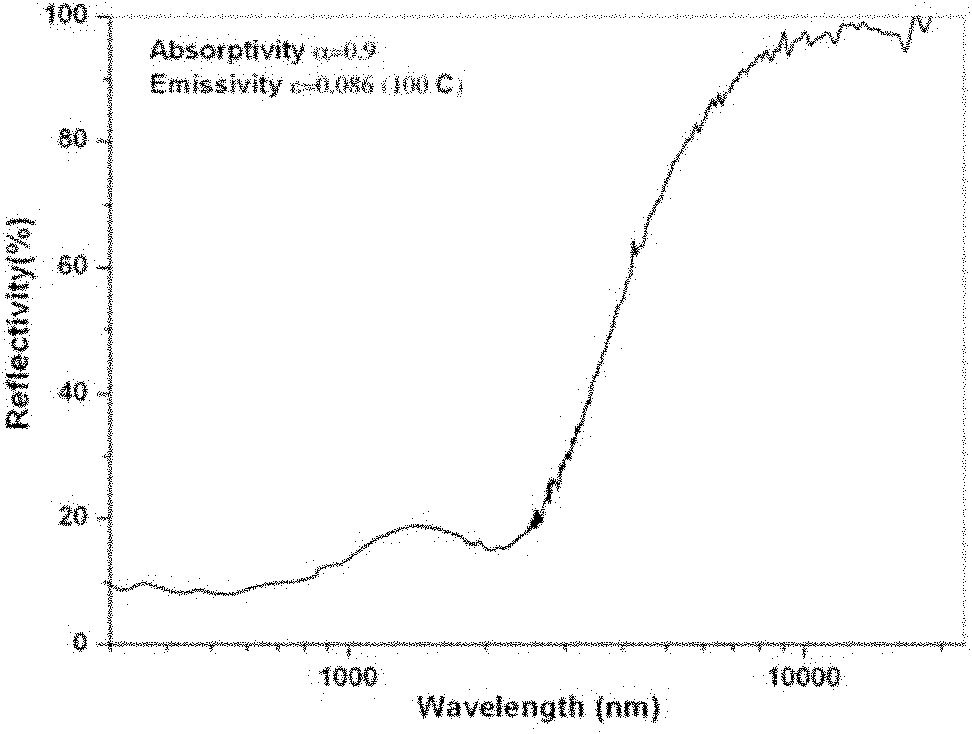

[0025] The properties of the resulting selective coating are as follows:

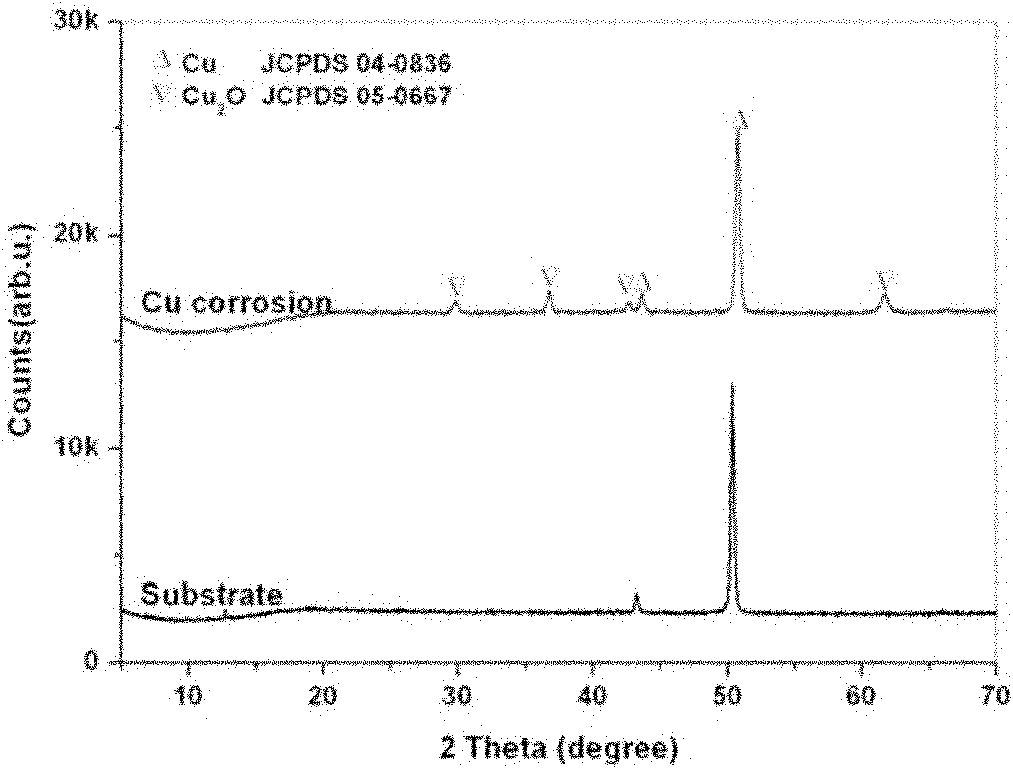

[0026] 1.XRD pattern

[0027] For the resulting Cu 2 The O selective coating has been...

Embodiment 2

[0034] (1) Potassium hydroxide and sodium hypochlorite are added to deionized water according to the molar ratio of 1:1, after fully stirring, a uniformly mixed solution is obtained, and put into a water bath at 60°C;

[0035] (2) Ammonium persulfate, ammonium chloride, and deionized water are mixed according to a molar ratio of 1:5:40, and after fully stirring, a uniform mixed solution is obtained;

[0036] (3) Cut the copper sheet into a suitable size and put it into the solution of step (2) for 10 seconds, then dry it in the air at 50°C, put it into the solution of step (1) and react for 30 minutes, take it out and pass through After repeated washing with deionized water, dry at 80°C in the air to obtain a selective coating for solar heat collectors.

Embodiment 3

[0038] (1) Sodium hydroxide and sodium chlorite are added to deionized water according to the molar ratio of 5:1, after fully stirring, a uniformly mixed solution is obtained, and put into a water bath at 20°C;

[0039] (2) Ammonium persulfate, ammonium chloride, deionized water and pyridine are mixed according to a molar ratio of 1:2:100:0.1, and after fully stirring, a uniform mixed solution is obtained;

[0040] (3) Cut the copper sheet into a suitable size and put it into the solution of step (2) to react for 30 minutes, then dry it in the air at 70°C, put it into the solution of step (1) and react for 10 minutes, take it out and pass through the After repeated washing with deionized water, it is dried in the air at 50°C to obtain a selective coating for solar heat collectors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emissivity | aaaaa | aaaaa |

| emissivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com