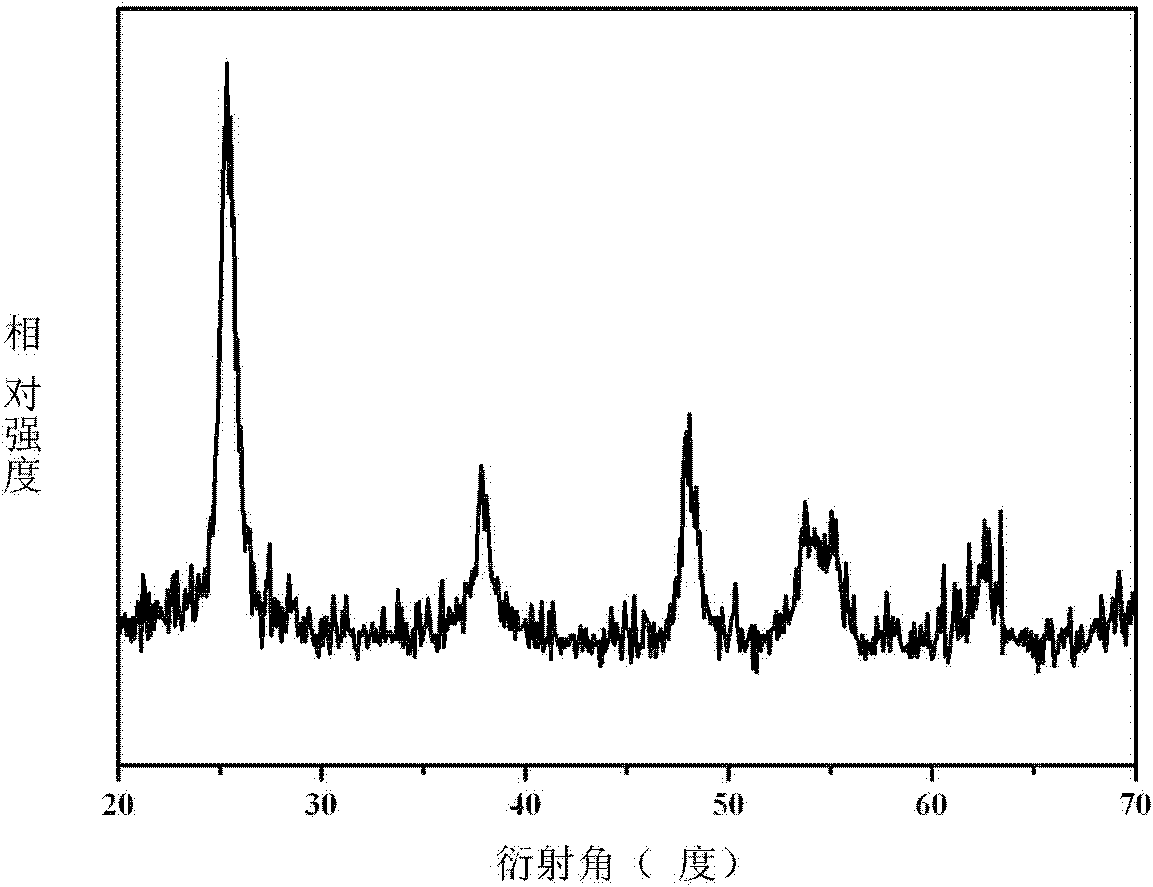

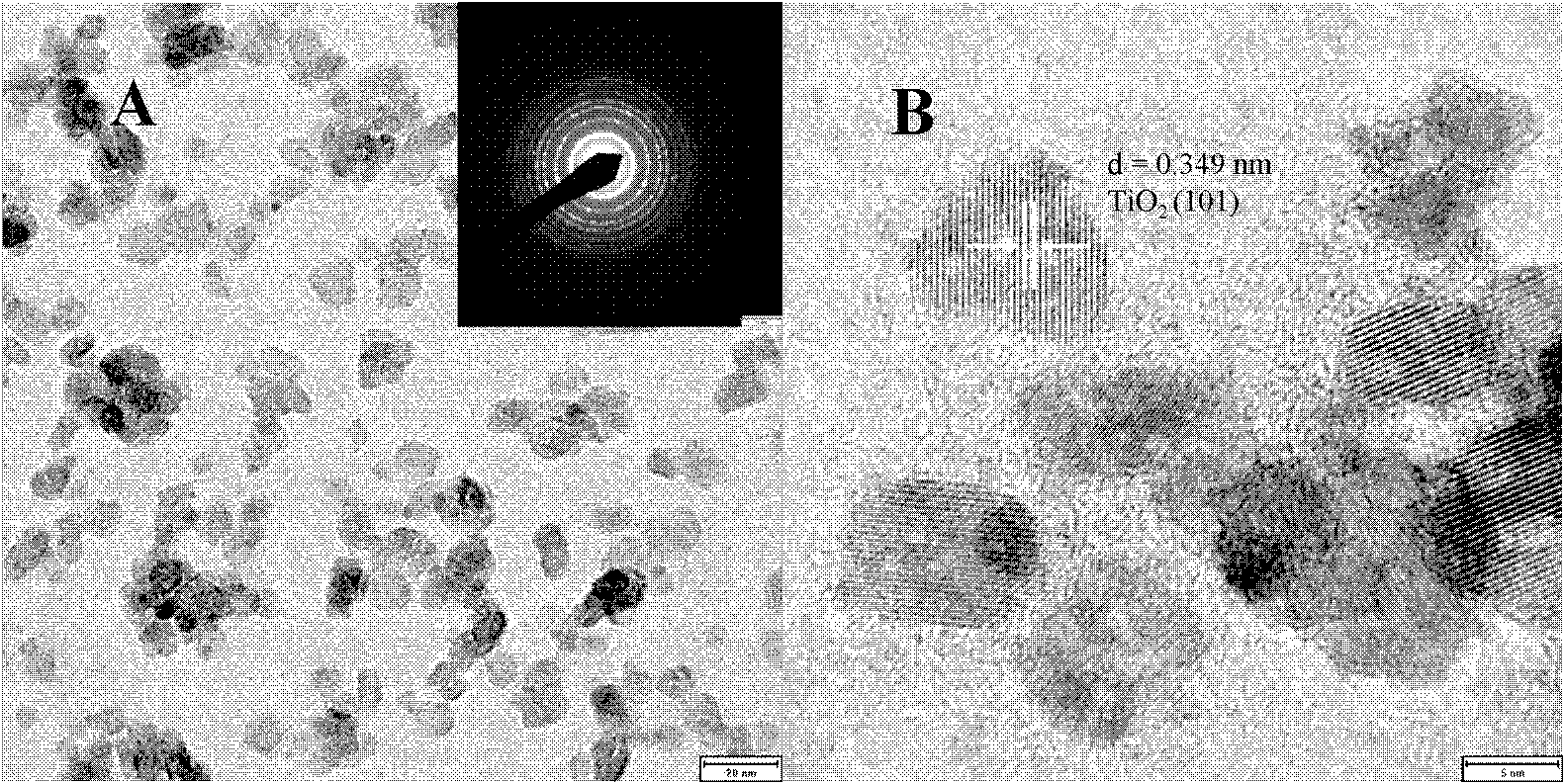

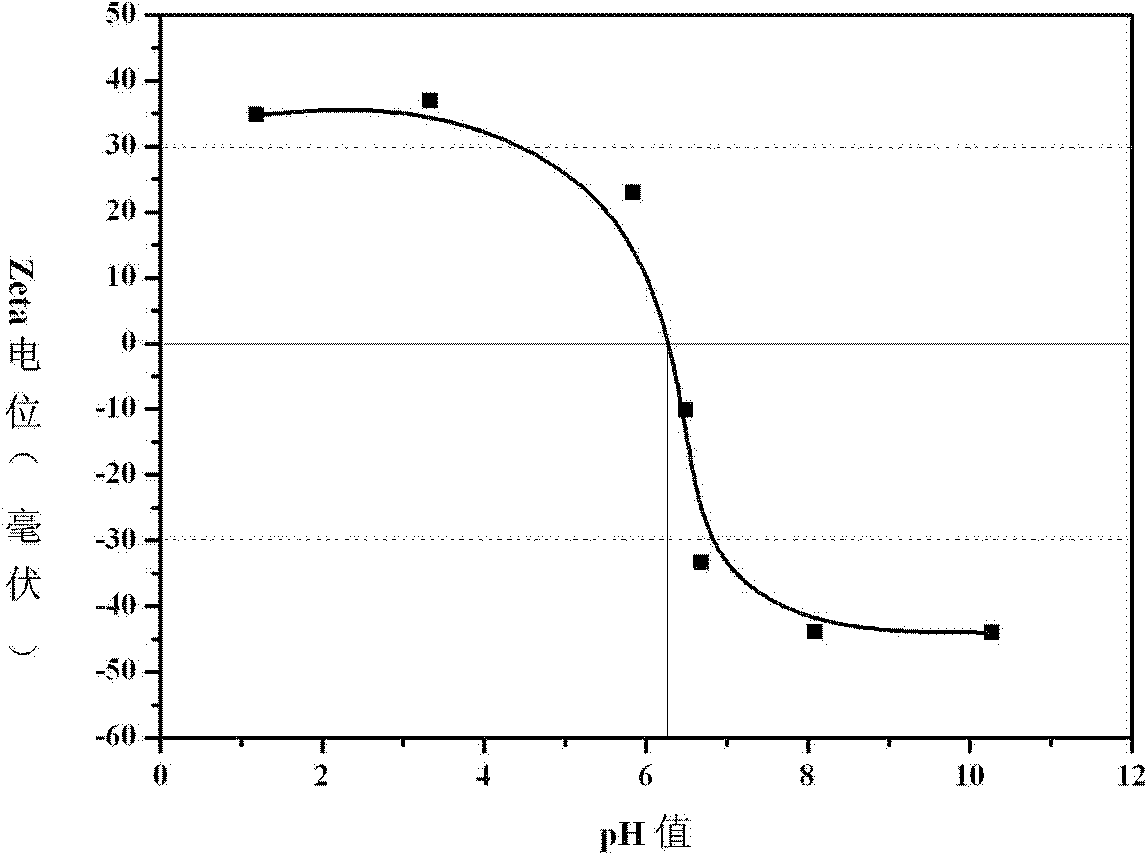

Titanium dioxide powder with ultrahigh water dispersion and high photocatalytic activity and preparation method thereof

A technology of titanium dioxide and catalytic activity, which is applied in the field of anatase titanium dioxide powder and its preparation, can solve problems such as complex methods, and achieve the effects of simple process, good photocatalytic activity and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of titanium dioxide powder with ultra-high water dispersibility and high photocatalytic activity, the preparation steps are:

[0037] Step 1: Add titanium tetrachloride to benzyl alcohol to configure it as a precursor, and the amount of titanium tetrachloride is 0.5 mol / liter;

[0038] Step 2: Solvothermally treat the precursor in step 1 at a temperature of 180°C for 20 hours;

[0039] Step 3: after step 2, centrifuge, and wash the product obtained by centrifugation with ethanol three times, and dry the product in air at 50°C for 12 hours to obtain titanium dioxide powder with ultra-high water dispersibility and high photocatalytic activity.

Embodiment 2

[0041] Preparation of titanium dioxide powder with ultra-high water dispersibility and high photocatalytic activity, the preparation steps are:

[0042] Step 1: Add tetraisopropanol titanate to benzyl alcohol to configure it as a precursor, and the amount of isopropyl titanate is 0.3 mol / liter;

[0043] Step 2: Solvothermally treat the precursor fluid in step 1 at a temperature of 200°C for 20 hours;

[0044] Step 3: After step 2, centrifuge, and wash the product obtained by centrifugation with ethanol three times, and dry the product in air at 120°C for 12 hours to obtain titanium dioxide powder with ultra-high water dispersibility and high photocatalytic activity.

Embodiment 3

[0046] Preparation of titanium dioxide powder with ultra-high water dispersibility and high photocatalytic activity, the preparation steps are:

[0047] Step 1: Add tetrabutyl titanate to benzyl alcohol, and configure the amount of n-butyl titanate precursor as 0.1 mol / L

[0048] Step 2: Solvothermally treat the precursor in step 1 at a temperature of 250°C for 20 hours;

[0049] Step 3: after step 2, centrifuge, and wash the product obtained by centrifugation with ethanol three times, and dry the product in air at 50°C for 12 hours to obtain titanium dioxide powder with ultra-high water dispersibility and high photocatalytic activity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com