Streptomyces griseofuscus strain and method for preparing epsilon-polylysine and salt thereof by utilizing same

A technology of Streptomyces tamarus and polylysine, which is applied in the fields of food engineering and fermentation engineering, can solve the problems of ε-polylysine production strains and technical limitations, and achieves the effects of convenient operation and extensive culture conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Slant medium: 1.0% glucose, 0.2% peptone, 0.1% yeast extract, 1.5% agar, pH 7.5, sterilized at 115°C for 20min.

[0050] Shake flask medium: glucose 5%, (NH 4 ) 2 SO 4 1%, K 2 HPO 4 0.08%, KH 2 PO 4 0.14%, MgSO 4 ·7H 2 O 0.05%, ZnSO 4 ·7H 2 O 0.005%, FeSO 4 ·7H 2 O 0.001%, yeast extract 0.5%, pH 6.8, sterilized at 115°C for 20min.

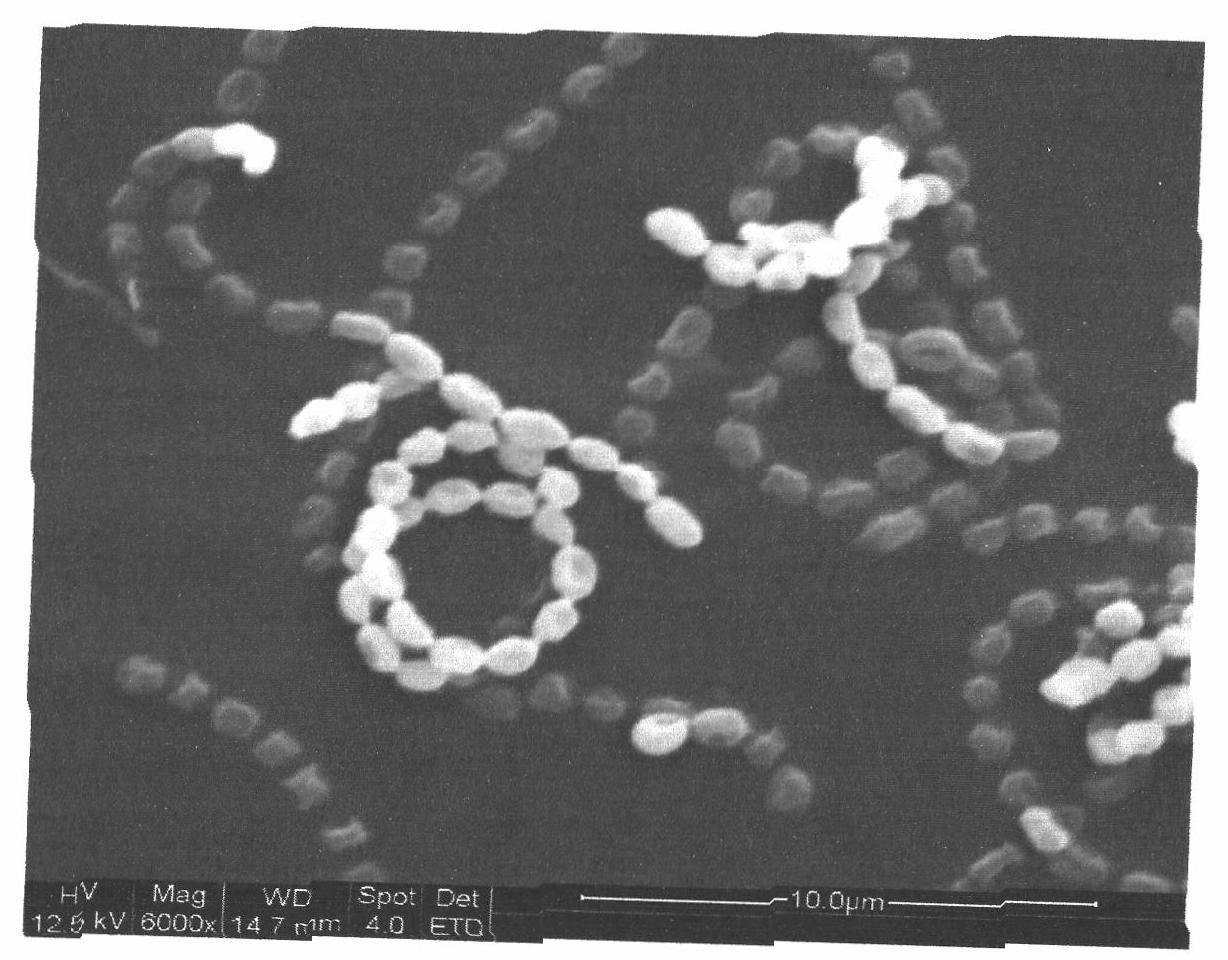

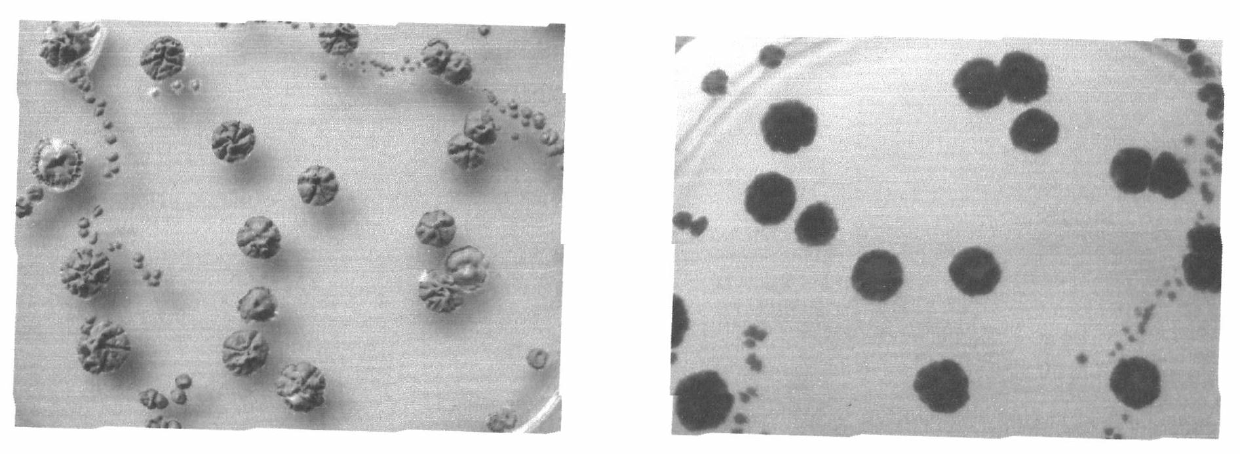

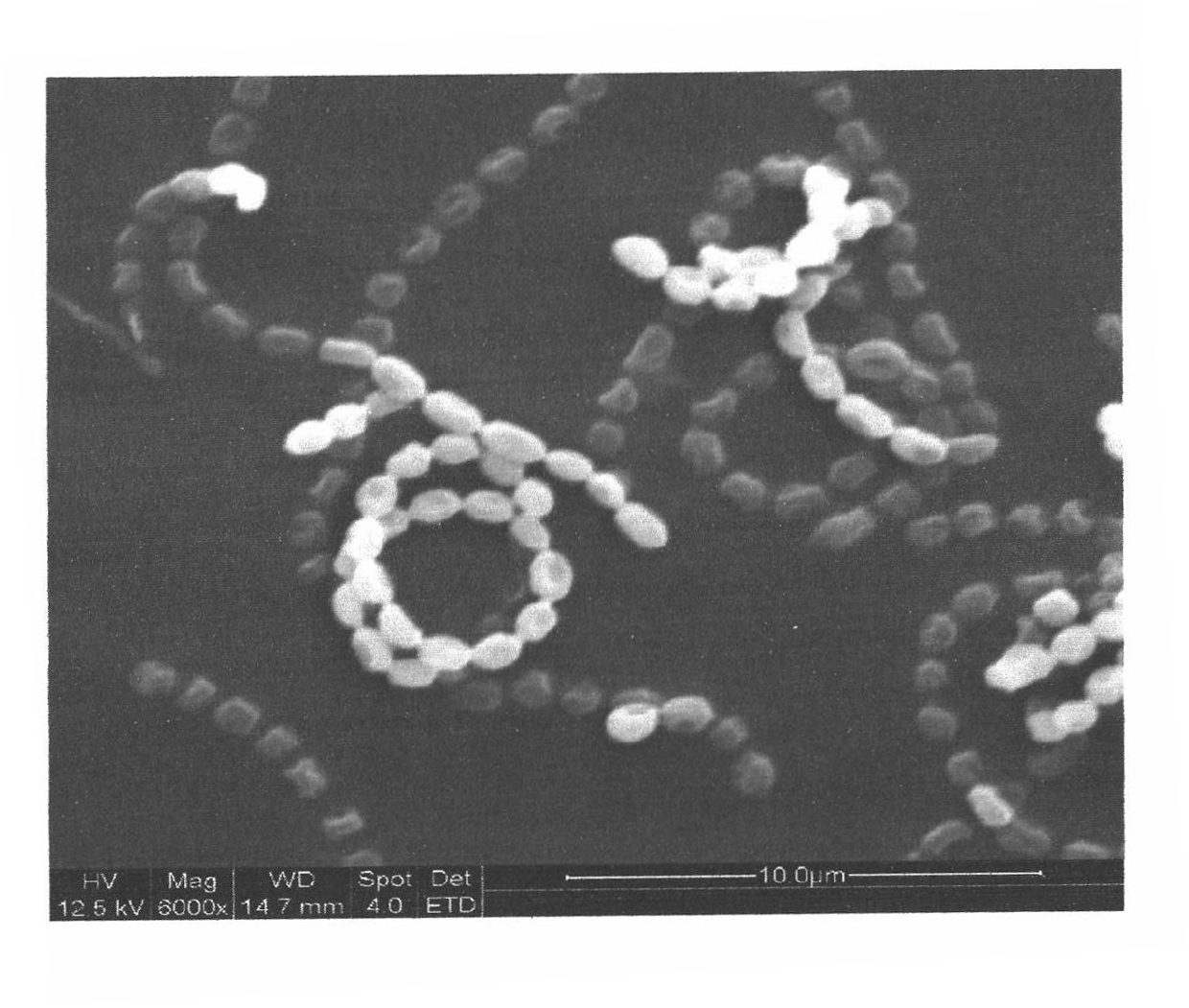

[0051] The purified CCTCC M 209211 was cultured on a slant medium at 30°C for 7 days, and then a ring of spores of this fungus was placed in the shake flask medium, cultured at 30°C for 72h, and the shaker flask rotated at 200r / min. Finally, the content of ε-polylysine in the fermented liquid was 0.7 g / L.

Embodiment 2

[0053] Fill a 5-liter glass stirred fermenter with 3L of shake flask medium and steam sterilize at 121°C for 15 minutes. CCTCC M 209211 was cultured with seed medium at 30°C for 24h, and the seed medium was the same as the fermentation medium. Insert 240ml of the seed liquid into the cooled fermented liquid, cultivate at 30°C, (ventilation ratio 1:2.5vvm, stirring speed is 350r / min), when 72h, the fermented liquid contains ε-polylysine 0.8g / L.

Embodiment 3

[0055] Same as Example 2, the fermentation process is controlled at pH 3.5, glucose and nitrogen sources are added to maintain a glucose concentration of about 10 g / L, and after 100 hours of fermentation, 20 g / L of ε-polylysine is accumulated in the fermentation broth. Centrifuge the fermentation broth to remove bacteria, adsorb on 732 cation exchange resin on the supernatant, wash with water, elute with ammonia water, concentrate the collected liquid to remove nitrogen, decolorize with activated carbon, continue to concentrate and precipitate with ethanol to obtain ε-polylysine hydrochloride 13.5g. The specific rotation of the product a 25 D =+57.1(c,1H 2 0), the molecular weight measured by SDS-PAGE electrophoresis is 5000Da.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com