Method for preparing polypeptide active substance from enzymolysis ginkgo protein

A technology of active substances and polypeptides, which is applied in the field of extraction and separation of plant active substances, can solve the problems of unfavorable absorption and achieve high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for enzymatically hydrolyzing ginkgo protein to prepare polypeptide active substances, comprising the following steps:

[0034] The first step is to prepare defatted ginkgo powder: shell the fresh ginkgo, remove the skin, and beat it into a paste at a temperature lower than 20°C with a beater. For example, the temperature can be selected as 19°C, 18°C, 14°C, 10°C. ℃, 8℃, 6℃, 5℃, 4℃, -2℃, -6℃, -8℃, then use non-polar solvent or supercritical CO 2 Extract the oil, then freeze-dry at -10°C--50°C, for example, freeze-dry for 6-50 hours, the time can be 20 hours, 40 hours, infrared rapid moisture determination, the weight percentage of water is less than 5%, broken, Sieve to obtain defatted ginkgo powder with a particle size of 100-200 mesh;

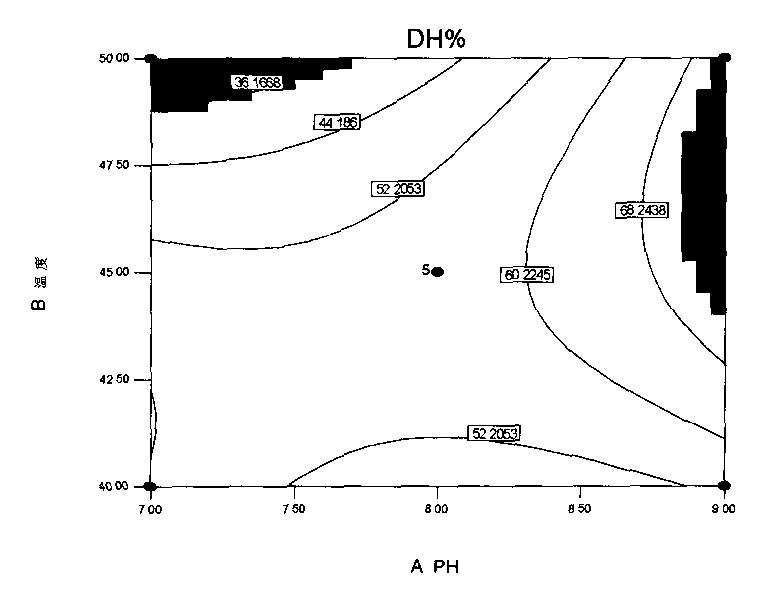

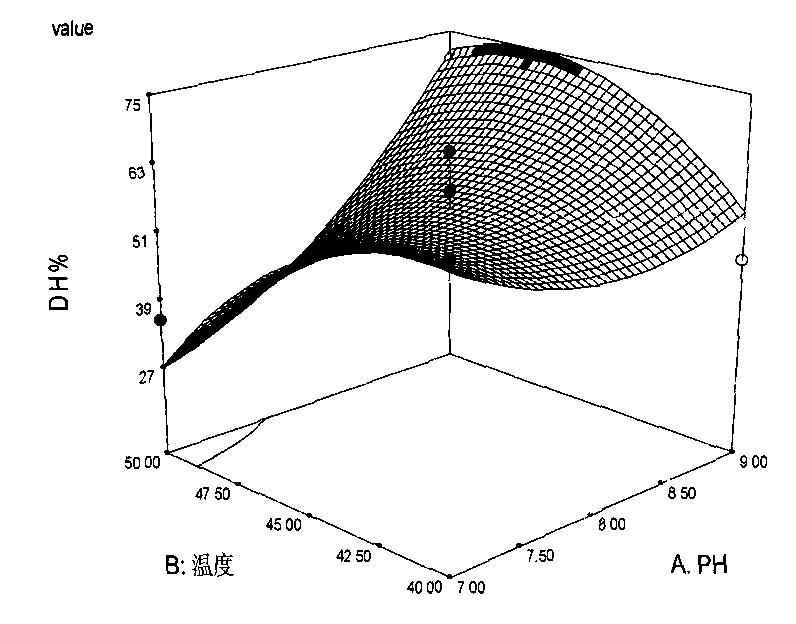

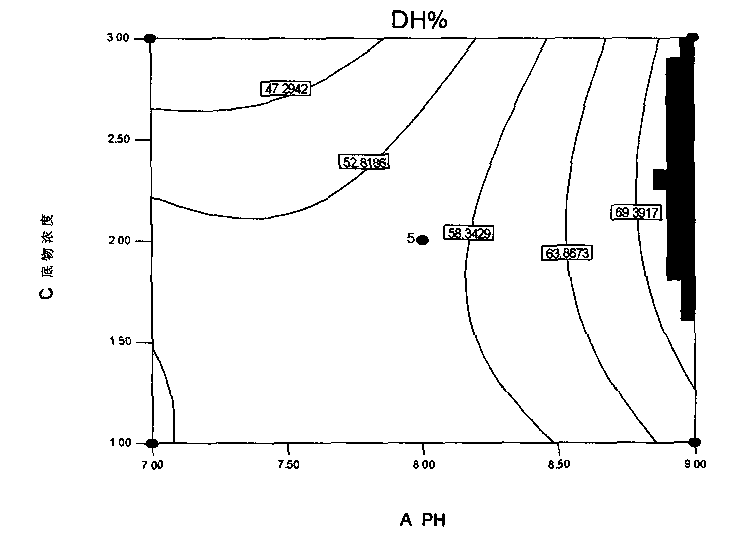

[0035]The second step, enzymatic hydrolysis of defatted ginkgo powder: the defatted ginkgo powder and deionized water are mixed in a mass ratio of 1:5 to 1:15, for example, 1:8, 1:9, 1:11, 1 : 14, then add enzyme wherein, th...

Embodiment 2

[0042] Example 2 Enzymatic hydrolysis of ginkgo protein to prepare polypeptide active substances

[0043] A method for efficiently enzymatically hydrolyzing ginkgo protein to prepare polypeptide active substances, comprising the following steps: the first step is to prepare defatted ginkgo powder: shell 100g-200g of fresh ginkgo, and choose 100g, 120g, 150g, 180g, 200g, remove the coat Skin, use a beater at 5°C, 10°C, 12°C, 15°C, 18°C, 20°C to make a paste, and then use a non-polar solvent or supercritical CO 2 Extract oil, freeze-dry at -10°C-50°C, preferably -20°C-40°C, for example, choose -25°C, -30°C, -40°C, prepare defatted ginkgo powder, infrared rapid moisture determination, moisture < 5% (mass percentage), broken, sieved to obtain the defatted ginkgo powder with a particle size of 100 to 200 mesh and a protein content of 11.3% (mass percentage);

[0044] The second step of enzymatic hydrolysis of defatted ginkgo powder: mix the defatted ginkgo powder and deionized wat...

Embodiment 3

[0052] Example 3 Enzymatic hydrolysis of ginkgo protein to prepare polypeptide active substances

[0053] Shell 100g ginkgo fruit, remove the skin, and beat it into a paste with a beater at 15°C, then extract it with an equal volume of n-hexane for 3-5 times, remove all the oil, and freeze-dry the water layer at -35°C for 40 hours. Crush it into defatted ginkgo powder with a particle size of 100 to 200 meshes. The infrared rapid determination shows that the water content is 4.45%, and the protein content is 11.8%.

[0054] Weigh 20g of defatted ginkgo powder, add 100ml of deionized water, add 2g of neutral protease with an enzyme activity of 400,000 u / g, adjust pH=8, hydrolyze at a temperature of 50°C for 5h, centrifuge after hydrolysis, and collect the supernatant. The supernatant passes through a 0.45μm cellulose membrane, the filtrate first passes through a 10,000MW polysulfone membrane, the permeate passes through a 3,000MW polysulfone membrane, the retentate is frozen and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com