Method for preparing hyper-dispersant used for mixed size

A technology of hyperdispersant and mixed slurry, which is applied in the direction of chemical instruments and methods, transportation and packaging, dissolution, etc., can solve the problems of polymer molecular weight increase, etc., and achieve the effects of reducing product viscosity, low raw material cost, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

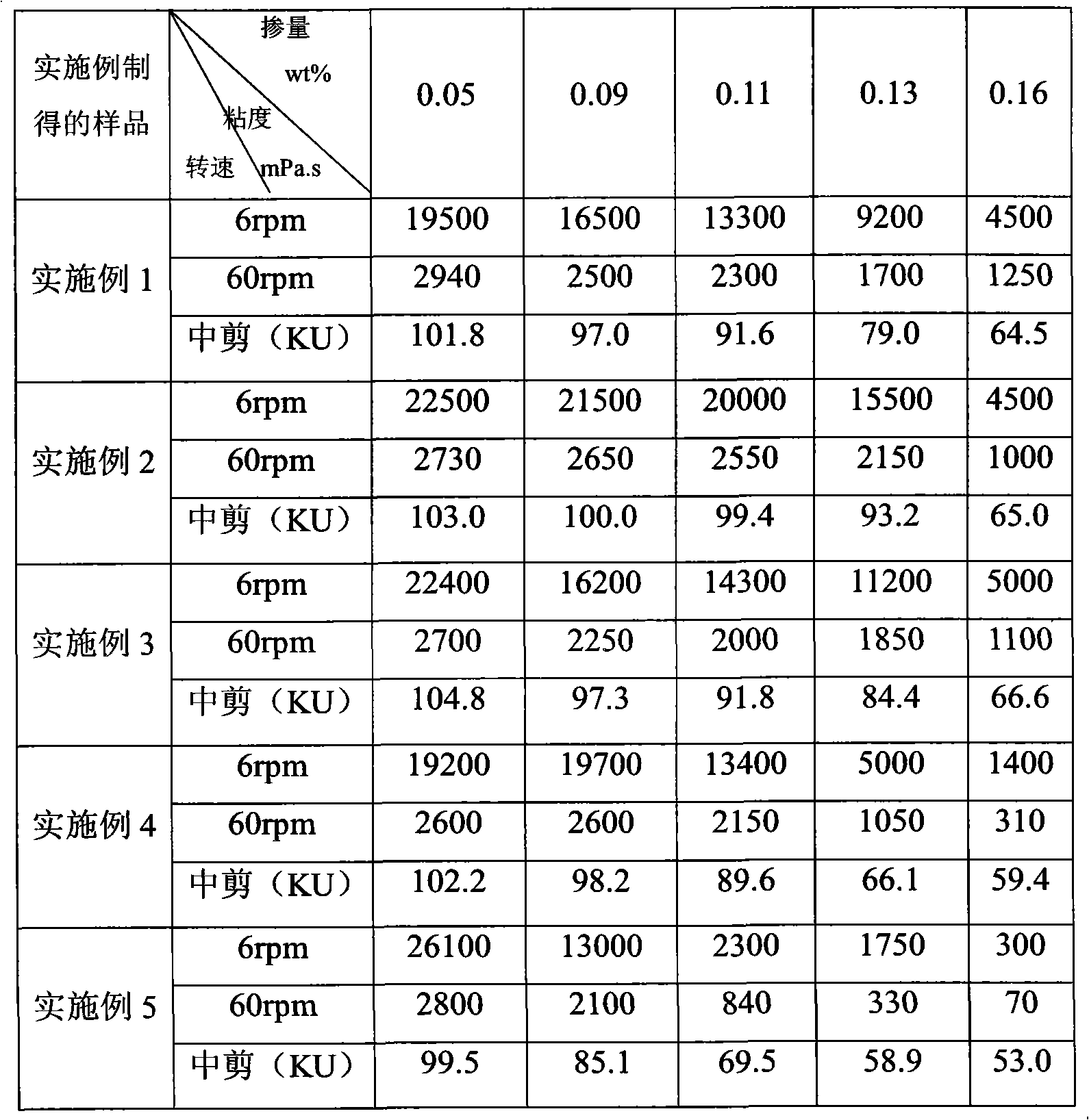

Embodiment 1

[0029] Configuration materials, material A: acrylic acid 70g, sodium methallyl sulfonate 1g, maleic anhydride 0.6g, styrene 0.2g, deionized water 20g, mix well at room temperature; material B: 30(wt)% hydrogen peroxide 0.5g, ammonium persulfate 8g, deionized water 55g; C1 material: 0.5g of 30(wt)% hydrogen peroxide; C2 material: 0.5g of 30(wt)% hydrogen peroxide; D material: 7.7g of acrylic acid, methallyl sulfonate 4 g of sodium nitrate, 2.4 g of maleic anhydride, 0.4 g of 3-mercaptopropionic acid, and 90 g of deionized water were mixed uniformly at room temperature. In the four-neck flask with condenser, thermometer, constant pressure dropping funnel, and mixer, first add material D, heat the water temperature of the constant temperature water bath to 60°C, add material C1 to the reaction kettle at one time, and start adding material A dropwise and B material, the dropping time is 3h, after the dropping, add C2 material to the reactor at one time, raise the temperature of th...

Embodiment 2

[0031]Configuration materials, material A: 277.2g methacrylic acid, 4g sodium 2-acrylammonium-2-methylpropanesulfonate, 2.4g maleic anhydride, 0.55g vinylpyrrolidone, 10g sodium bisulfite, 80g deionized water , mix well at room temperature; material B: potassium persulfate 33.6g, deionized water 220g; material C1: ammonium persulfate 2g, deionized water 10g; material C2: ammonium persulfate 2g, deionized water 10g; material D: 30.8 g of acrylic acid, 6 g of sodium methallyl sulfonate, 9.6 g of maleic anhydride, 1 g of 2-mercaptobutanol, 3 g of sodium bisulfite, and 220 g of deionized water were mixed uniformly at room temperature. In a four-necked flask with a condenser, a thermometer, a constant pressure dropping funnel, and a mixer, first add the mixed material D, and after raising the water temperature of the constant temperature water bath to 70°C, add C1 material to the reaction kettle at one time, and start adding A separately. Material and material B, the dropping time ...

Embodiment 3

[0033] Configuration materials, material A: 550g of acrylic acid, 8g of sodium methallyl sulfonate, 4.8g of maleic anhydride, 54g of methoxypolyethylene glycol (meth)acrylate (nEO=23), 30g of sodium sulfite, deionized 160g of water, mix well at room temperature; material B: potassium persulfate 121.6g, deionized water 440g; material C1: potassium persulfate 4g; material C2: potassium persulfate 4g; material D: acrylic acid 77g, methallyl Sodium sulfonate 5g, maleic anhydride 3g, sodium sulfite 10g, deionized water 440g, mix well at room temperature. In a four-necked flask with a condenser, a thermometer, a constant pressure dropping funnel, and a mixer, and a constant temperature water bath, first add the mixed material D, and after the temperature rises to 80°C, add the C1 material to the reaction kettle at one time, and start adding the A material dropwise. And material B, the dropping time is 3h, after the dropping, add C2 to the reactor at one time, raise the temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com