Rapid preparation method of high-dispersible TiO2 nano crystal sol

A high-dispersion, nanocrystalline technology, applied in nanotechnology, chemical instruments and methods, titanium oxide/hydroxide, etc., to achieve the effects of simple and easy to control, uniform and stable sol, and high photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment one: Specific steps are as follows:

[0020] A. Configure 0.1M Ti(SO 4 ) 2 of aqueous solution.

[0021] B. Add ammonia water to adjust the pH value of the solution to 7.5-8.5, and generate a precipitate, which is washed with H 2 o 2 Complexation reflux degelation to obtain peroxotitanic acid sol.

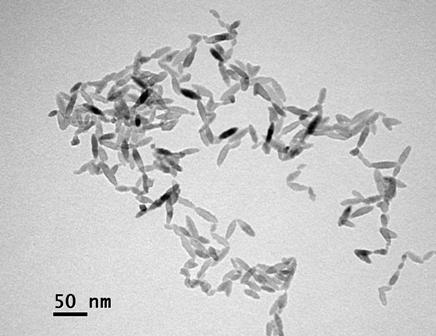

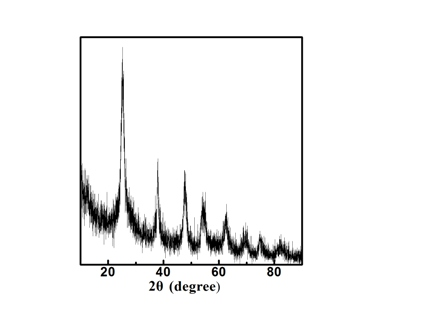

[0022] C. Move the above-mentioned peroxotitanic acid sol into the closed high-temperature reaction kettle of the microwave sample preparation system, and crystallize it for 30 minutes under the power of 800W and the temperature of 160°C to obtain TiO 2 nanocrystalline sol

[0023] D. Catalytic degradation of methylene blue was carried out with self-made photocatalytic device.

Embodiment 2

[0024] Embodiment two: This embodiment is basically the same as Embodiment 1, except that the solvent used is ethanol.

Embodiment 3

[0025] Embodiment three: This embodiment is basically the same as Embodiment 1, except that the solvent used is propanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com