Copper alloy material for electrical and electronic components, and manufacturing method therefof

A technology of electronic components and copper alloys, applied in the direction of conductive materials, conductive materials, electrical components, etc., can solve problems such as non-conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

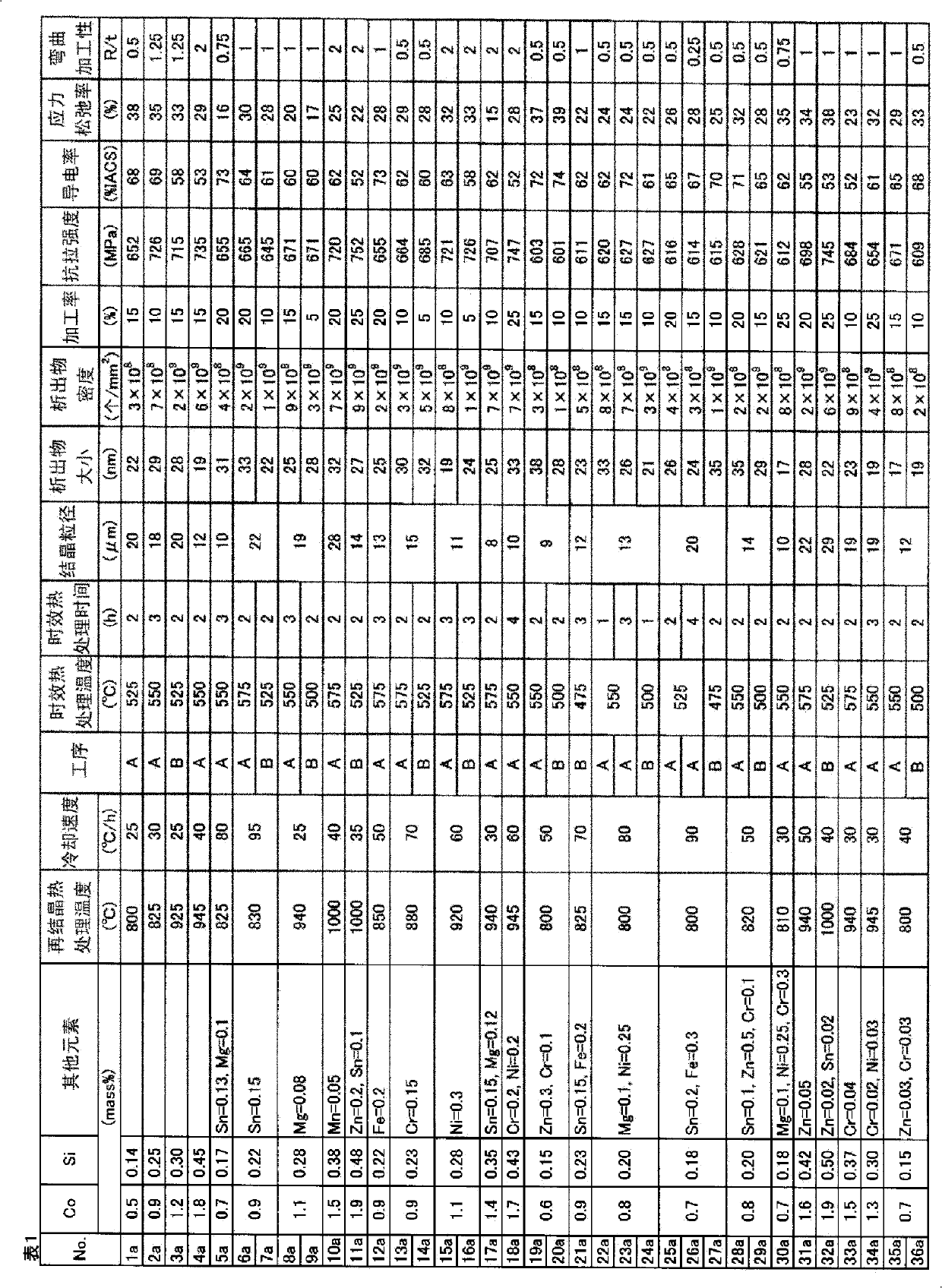

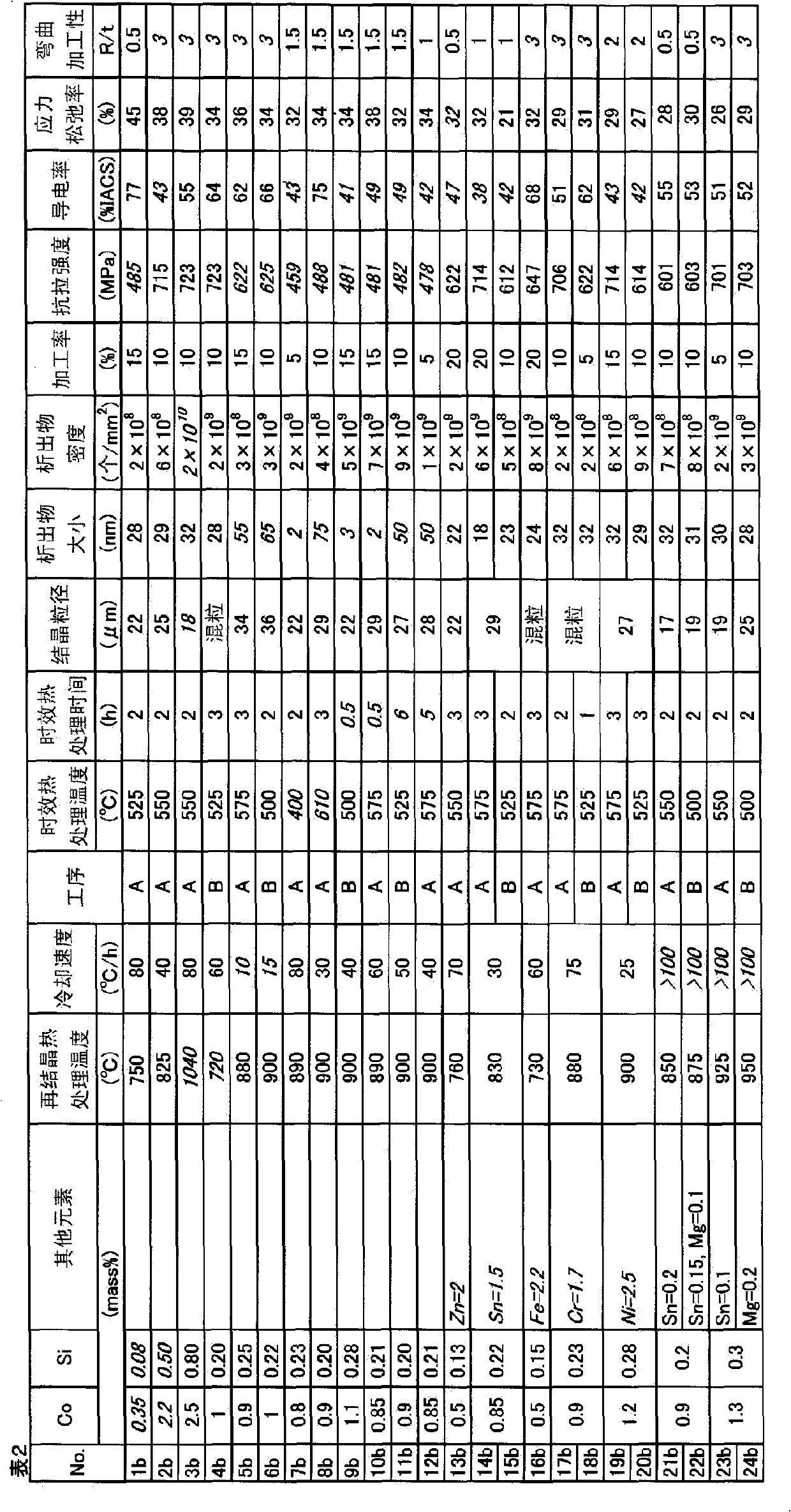

[0175] Melt alloys (1a-36a, 1b-24b) containing the components shown in Tables 1 and 2, and the remainder consisting of Cu and unavoidable impurities in a high-frequency melting furnace, and cool them at a rate of 10-30K / sec. Speed casting yielded an ingot with a thickness of 30 mm, a width of 100 mm, and a length of 150 mm.

[0176] After keeping the obtained ingot at a temperature of 930-970° C. for 0.5-1.0 hours, hot rolling is carried out to obtain a hot-rolled plate with a plate thickness t=12 mm, and both sides of the ingot are milled off by 1 mm to obtain a plate thickness t = 10 mm, and then finish processing to a plate thickness t=0.3 mm by cold rolling, and perform recrystallization heat treatment at a temperature of 700° C. or higher and 1025° C. or lower. The final product is produced by subjecting the prepared material to any of the following two procedures.

[0177] Step A: recrystallization heat treatment-aging heat treatment (at a temperature of 500-600°C for...

Embodiment 2

[0203] The copper alloy raw materials containing the components shown in Tables 3 and 4, and the remainder consisting of Cu and unavoidable impurities are melted in a high-frequency melting furnace, cast at a cooling rate of 10 to 30 K / s, and a thickness of An ingot of 30mm, width 100mm, and length 150mm.

[0204] There are many known documents that specify O (oxygen) in the raw material or material in Cu with Si added, but when an element with higher oxidizing property than Cu is added, if O is present, it will be oxidized before Cu, so Si as an added element The yield rate is not stable. Therefore, it is a well-known technique for those skilled in the art to regulate the O concentration in the raw material or material when adding an element whose oxidizing property is higher than Cu. Similarly, there are many known documents that specify H (hydrogen) together with O. H and O are often attached to the surface of the raw material in the state of moisture. If pre-treatment for...

Embodiment 3

[0233] An alloy containing the components shown in Table 5 and the remainder consisting of Cu and unavoidable impurities was melted in a high-frequency melting furnace, and cast at a cooling rate of 10 to 30 K / s to obtain a 160 mm wide, 30 mm thick, Ingots with a length of 180 mm. The cooling temperature is carried out under the condition that cracks and the like do not occur in the ingot.

[0234] After keeping the obtained ingot at a temperature of 1000° C. for 30 minutes, hot rolling is carried out to obtain a hot-rolled sheet with a thickness of t=12 mm, and each end of the two sides is milled off by 1 mm so that the thickness of the sheet is t=10 mm, and then After finishing by cold rolling to a plate thickness t=0.3 mm, recrystallization heat treatment was performed at a temperature in the range of 800 to 1025°C. The temperature of the recrystallization heat treatment was changed as described in Table 5 to Table 6 according to the addition amount of Co and the like. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com