Special compound enzyme for yeast hydrolysis and preparation method thereof

A yeast hydrolysis and compound enzyme technology, applied in biochemical equipment and methods, food preparation, enzymes, etc., can solve the problems of low wall breaking rate, low degree of hydrolysis, low yield, etc., and achieve rich nutrition, excellent functionality, The effect of high degree of hydrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

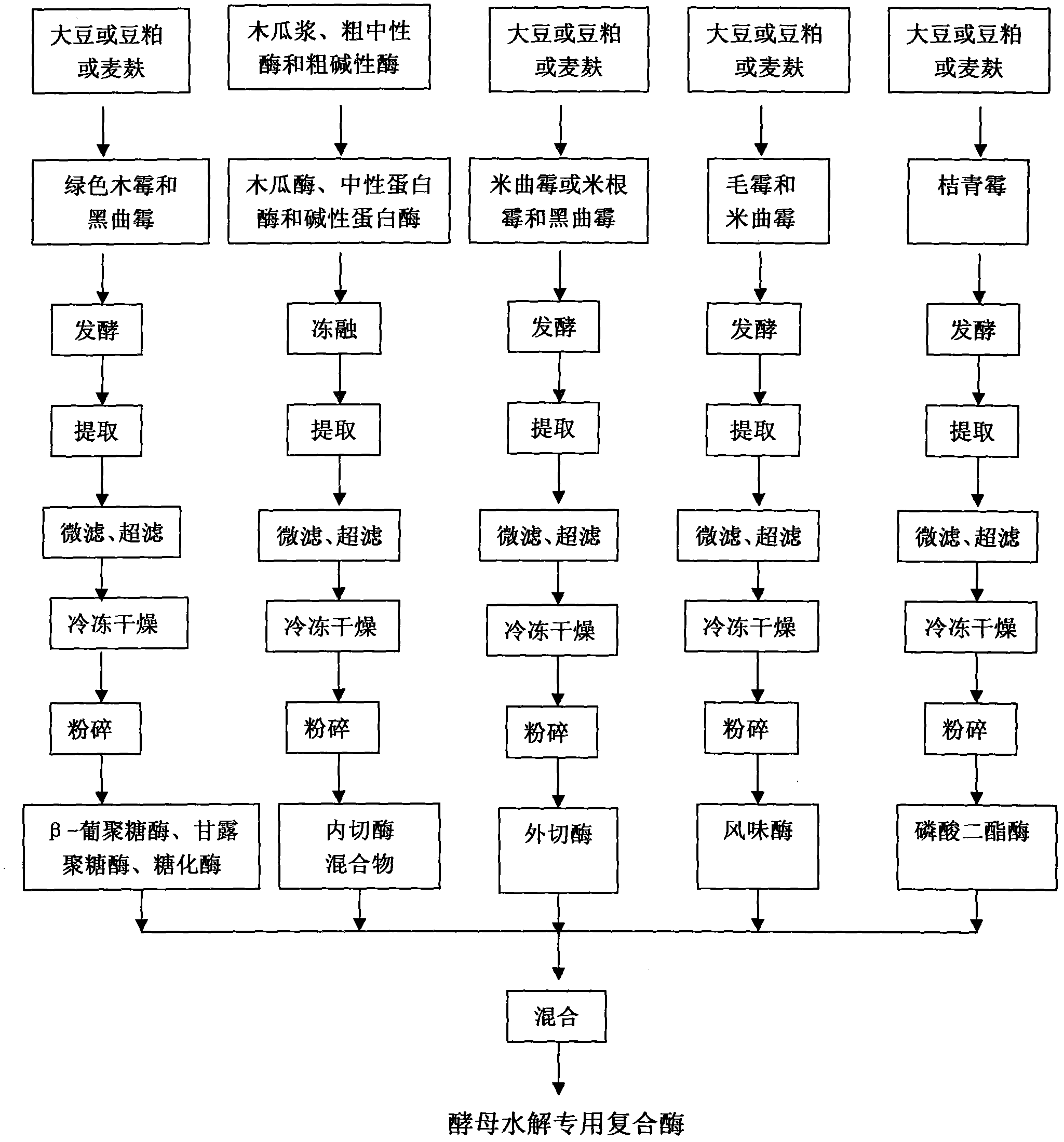

[0047] Preparation of β-glucanase: use soybean as raw material, crush, sterilize, add Trichoderma viride (Trichoderma viride) strain or Aspergillus niger (Aspergillus niger) strain, ferment for 3 days according to the conventional method, then extract and separate , ultrafiltration, freeze-drying, and crushing to obtain β-glucanase, which is stored for future use.

[0048] Preparation of mannanase: use soybean as raw material, pulverize, sterilize, add Trichoderma viride or Aspergillus niger, ferment for 3 days according to conventional methods, then extract, separate and ultrafilter , freeze-dried, and pulverized to obtain mannanase, which was stored for future use.

[0049] Preparation of glucoamylase: use soybean as raw material, pulverize, sterilize, add Trichoderma viride (Trichoderma viride) strain or Aspergillus niger (Aspergillus niger) strain, ferment for 3 days according to the conventional method, then extract, separate, ultrafilter, Freeze-dried and pulverized to ...

Embodiment 2

[0064] Preparation of β-glucanase: use soybean meal as raw material, pulverize, sterilize, add Trichoderma viride (Trichoderma viride) strain or Aspergillus niger (Aspergillus niger) strain, ferment for 4 days according to the conventional method, then extract and separate , ultrafiltration, freeze-drying, and crushing to obtain β-glucanase, which is stored for future use.

[0065] Preparation of mannanase: use soybean meal as raw material, pulverize, sterilize, add Trichoderma viride (Trichoderma viride) strain or Aspergillus niger (Aspergillus niger) strain, ferment for 4 days according to conventional method, then extract, separate, supersede Filter, lyophilize, and pulverize to obtain mannanase, which is stored for future use.

[0066] Preparation of glucoamylase: use soybean meal as raw material, pulverize, sterilize, add Trichoderma viride (Trichoderma viride) strain or Aspergillus niger (Aspergillus niger) strain, ferment for 4 days according to the conventional method,...

Embodiment 3

[0081] Preparation of β-glucanase: use wheat bran as raw material, pulverize, sterilize, add Trichoderma viride (Trichoderma viride) strain or Aspergillus niger (Aspergillus niger) strain, ferment for 3 days according to the conventional method, then extract, Separation, ultrafiltration, freeze-drying, and pulverization to obtain β-glucanase, which is stored for future use.

[0082] Preparation of mannanase: use wheat bran as raw material, pulverize, sterilize, add Trichoderma viride (Trichoderma viride) strain or Aspergillus niger (Aspergillus niger) strain, ferment for 3 days according to the conventional method, then extract, separate, Mannanase was obtained by ultrafiltration, freeze-drying and pulverization, which was stored for future use.

[0083] Preparation of glucoamylase: use wheat bran as raw material, pulverize, sterilize, add Trichoderma viride (Trichoderma viride) strain or Aspergillus niger (Aspergillus niger) strain, ferment for 3 days according to the convent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com