Method for recycling silicon carbide micropowder from waste mortar produced by cutting silicon wafer

A silicon carbide micropowder and silicon wafer cutting technology, which is applied in the direction of lubricating compositions, etc., can solve the problems of living environment pollution, achieve the effects of small environmental pollution, improve use efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

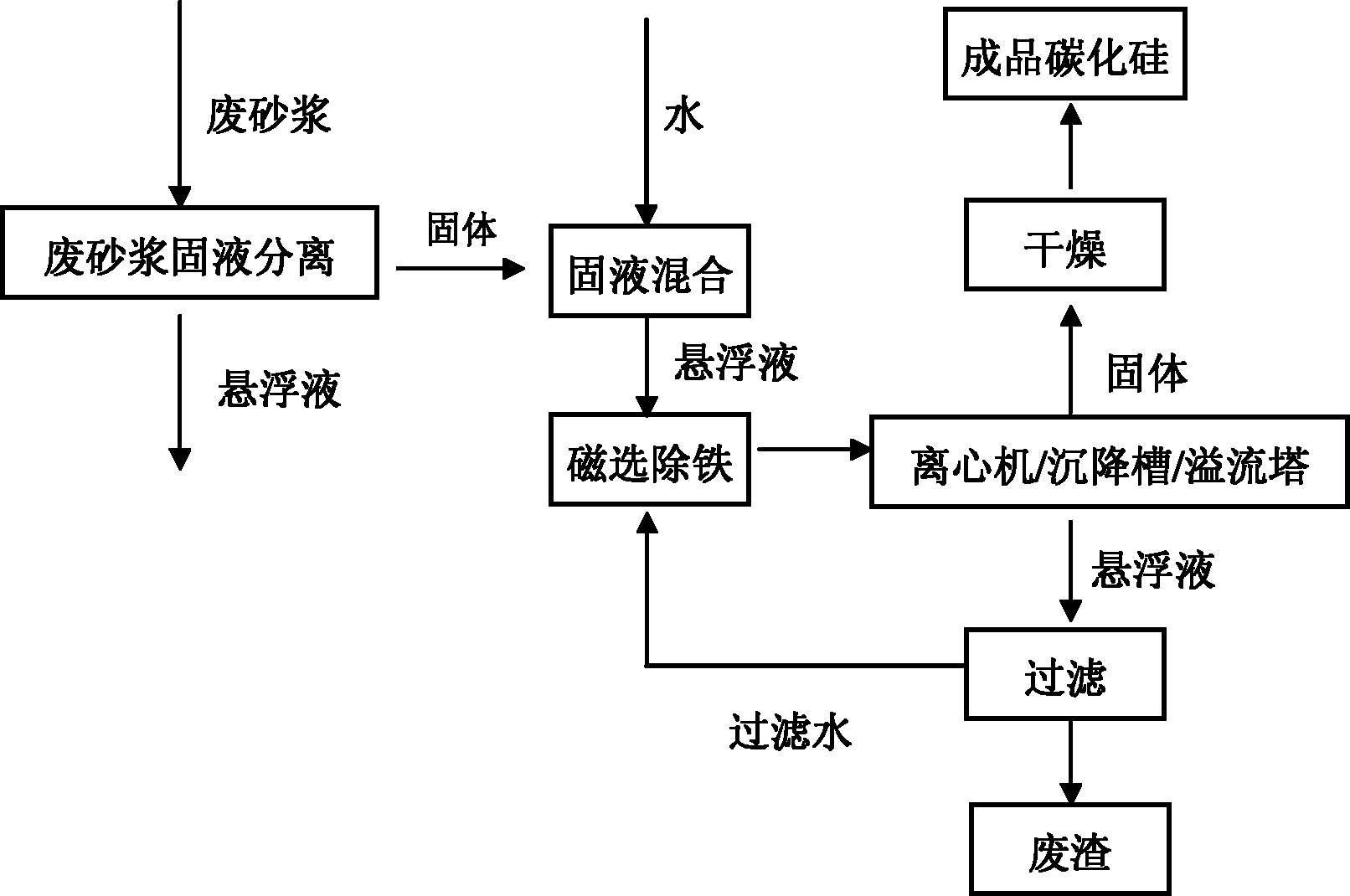

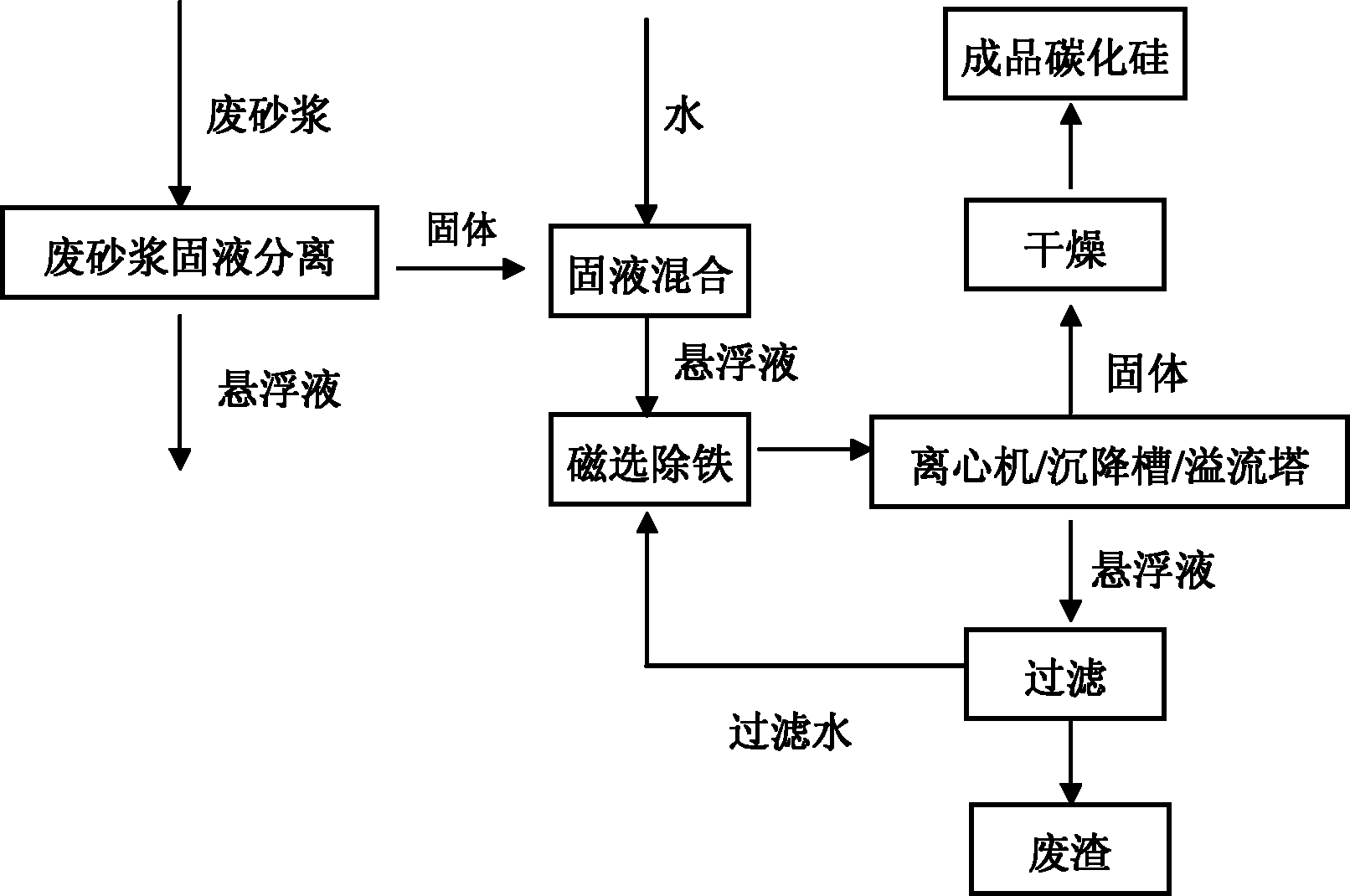

Method used

Image

Examples

Embodiment 1

[0037] a Use a centrifugal separator to separate the waste mortar from solid to liquid, remove the liquid components, and obtain solid precipitates.

[0038] b Use a mixer to mix the solid precipitate obtained in a with water and dispersant stearic acid to obtain a suspension with a certain concentration.

[0039] c Using a downstream permanent magnet magnetic separator to repeatedly remove iron and continuously remove the ferroalloy in the suspension to obtain a suspension with less ferroalloy content.

[0040]d The suspension treated in step c is repeatedly mixed and settled by centrifugal sedimentation, the upper suspension is separated from the lower sediment by pouring, and the upper suspension is continuously removed to obtain a concentrated suspension with a higher silicon carbide content.

[0041] c. Use a vibrating fluidized bed dryer to dry the concentrated suspension obtained in step d, and then use a turbine classifier to achieve powder classification to further ob...

Embodiment 2

[0043] a Use a plate and frame filter to separate the waste mortar from solid to liquid, remove the liquid components, and obtain solid precipitates.

[0044] b Use a mixer to mix the solid precipitate obtained in a with water and the dispersant sodium dodecylsulfonate to obtain a suspension with a certain concentration.

[0045] c Use permanent magnetic iron remover to remove iron repeatedly, continuously remove the ferroalloy in the suspension, and obtain a suspension with less ferroalloy content.

[0046] d Use a settler to repeatedly mix and settle the suspension treated in step c, and then continuously collect the lower solid precipitate by means of valve discharge to obtain a solid precipitate with a higher silicon carbide content.

[0047] e Use a rotary drum dryer to dry the solid precipitate obtained in step d, and then use a cyclone separator to achieve powder classification, and further obtain silicon carbide micropowder with a higher concentration.

Embodiment 3

[0049] aUse a vacuum filter to separate the waste mortar from solid to liquid, remove the liquid components, and obtain solid precipitates.

[0050] b Use a mixing tank to mix the solid precipitate obtained in a with water and the dispersant sodium hexametaphosphate to obtain a suspension with a certain concentration.

[0051] c Using a semi-counter-current electromagnetic separator to repeatedly remove iron, continuously remove the ferroalloy in the suspension, and obtain a suspension with less ferroalloy content.

[0052] d Using an overflow tower to repeatedly mix and settle the suspension treated in step c, and then use continuous hydraulic countercurrent overflow washing to continuously remove the upper suspension to obtain a concentrated suspension with a higher silicon carbide content.

[0053] e Use a high-efficiency cyclone dryer to dry the concentrated suspension obtained in step d, and then use a turbo classifier to achieve powder classification, and further obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com