Macroporous spherical polyacrylonitrile bead body prepared from waste acrylic fibers and preparation process thereof

A polyacrylonitrile bead, polyacrylonitrile technology, applied in recycling technology, other chemical processes, alkali metal oxides/hydroxides, etc., to achieve the effect of broadening development paths, realizing efficient recycling and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

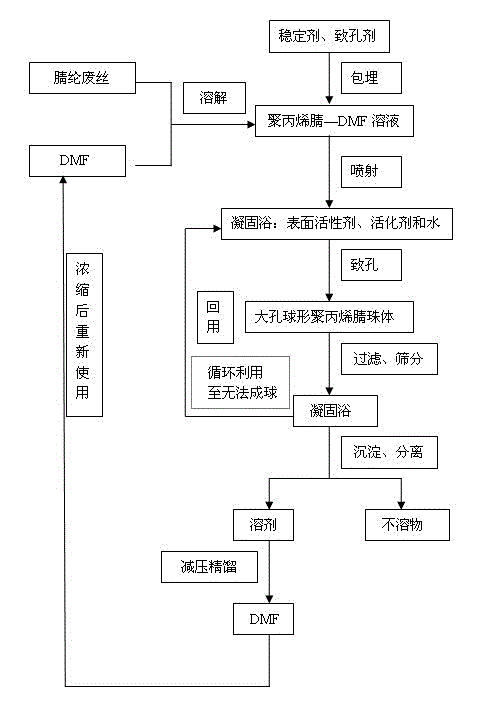

[0042] Embodiment 1: the process steps and order of the present embodiment are as figure 1 shown. Specific steps are as follows:

[0043] (1) dissolve

[0044] Raw materials and formula (unit-kilogram) of the present embodiment:

[0045]Acrylic waste silk (provided by Desheng Textile Trading Co., Ltd., Shishi City, Fujian Province): 14 kg

[0046] DMF: 70kg

[0047] Stabilizer (mixture of oxalic acid and isoascorbic acid, mass ratio 4:1): 0.5 kg

[0048] Porogen (mixture of activated carbon and calcium carbonate, mass ratio 1:9): 15.5 kg

[0049] Dissolving process steps and process parameters: Put the above-mentioned amount of waste acrylic fibers into the reactor filled with the above-mentioned amount of DMF, control the reaction temperature at 95°C, and dissolve for 40 minutes to form polyacrylonitrile with a mass fraction of 16.7%— After the DMF solution, add 0.5 kg of a stabilizer of a mixture of oxalic acid and erythorbic acid and 15.5 kg of a porogen of a mixture...

Embodiment 2

[0058] Embodiment 2: the process steps and order of the present embodiment are as figure 1 shown. Specific steps are as follows:

[0059] (1) dissolve

[0060] Raw materials and formula (unit-kilogram) of the present embodiment:

[0061] Acrylic waste silk (provided by Qingyuan Printing and Dyeing Development Co., Ltd., Shishi City, Fujian Province): 12 kg

[0062] DMF: 72 kg

[0063] Stabilizer (mixture of oxalic acid and diethylamide, mass ratio 2:3): 1.0 kg

[0064] Porogen (mixture of activated carbon and calcium carbonate, mass ratio 2:8): 15 kg

[0065] Dissolution process steps and process parameters: Put the above-mentioned amount of waste acrylic fibers into the reactor filled with the above-mentioned amount of DMF, control the reaction temperature at 85°C, dissolve and react for 40 minutes, and form polyacrylonitrile with a mass fraction of 14.3%— After the DMF solution, 1.0 kg of a stabilizer of a mixture of oxalic acid and diethylamide and 15 kg of a porogen...

Embodiment 3

[0074] Embodiment 3: the process steps and order of the present embodiment are as figure 1 shown. Specific steps are as follows:

[0075] (1) dissolve

[0076] Raw materials and formula (unit-kilogram) of the present embodiment:

[0077] Acrylic waste silk (Jiahe Knitting Co., Ltd., Changle City, Fujian Province): 10 kg

[0078] DMF: 70kg

[0079] Stabilizer (potassium oxalate): 0.5 kg

[0080] Porogen (mixture of activated carbon and calcium carbonate, mass ratio 1:12): 19.5 kg

[0081] Dissolution process steps and process parameters: put 10.0 kg of acrylic waste silk into a reactor filled with 70 kg of N,N-dimethylformamide (DMF for short), control the reaction temperature at 75°C, and dissolve for 30 minutes. After forming a polyacrylonitrile-DMF solution with a mass fraction of 12.5%, 0.5 kg of a stabilizer of potassium oxalate and 19.5 kg of a porogen of a mixture of activated carbon and calcium carbonate were added. This process step is carried out under normal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com