Phase change material capsule and preparation method thereof

A phase change material and capsule technology, applied in the field of phase change material capsules and their preparation, phase change material microcapsules or nanocapsules, to achieve the effects of wide application range, convenient industrial implementation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

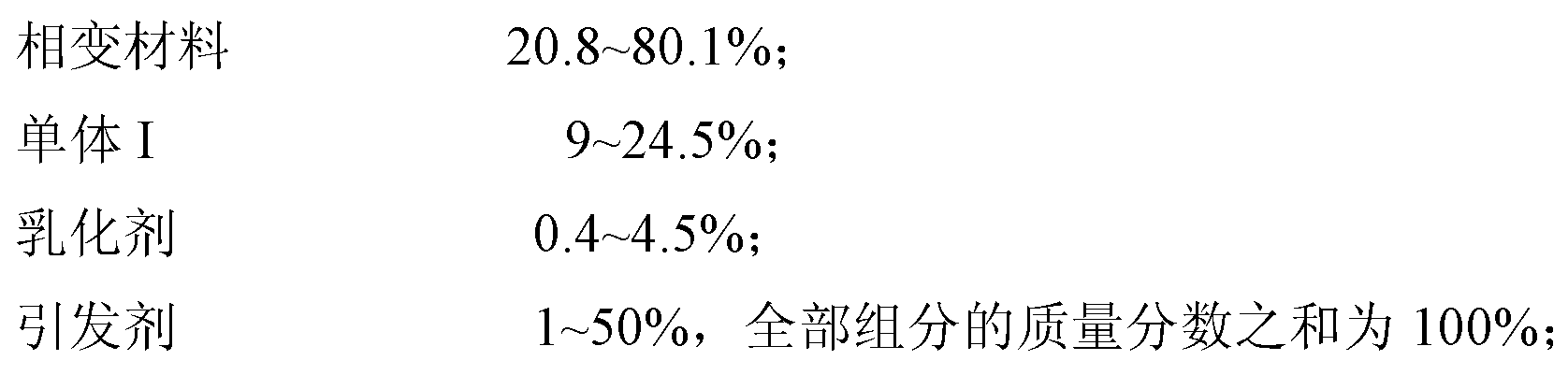

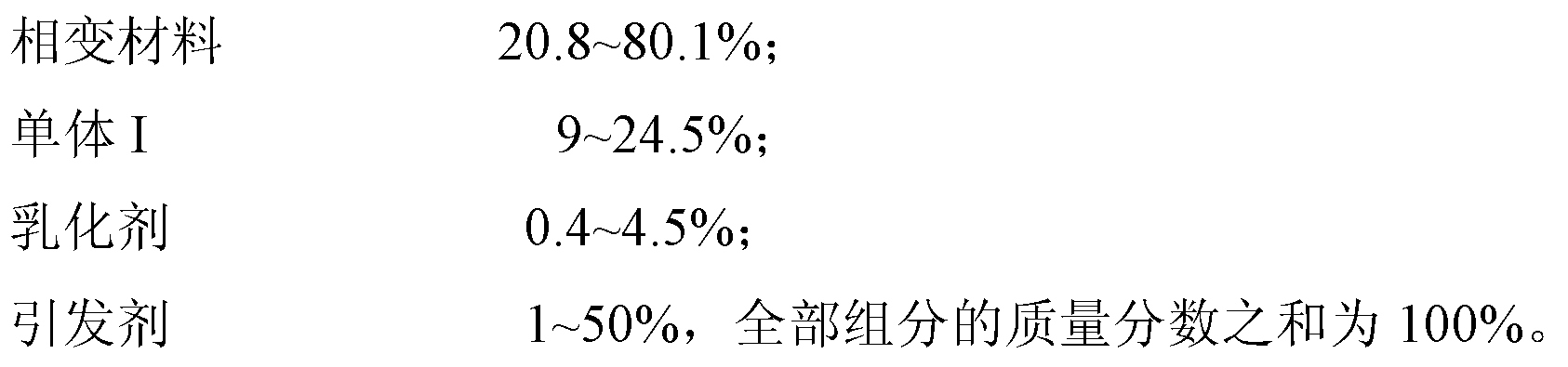

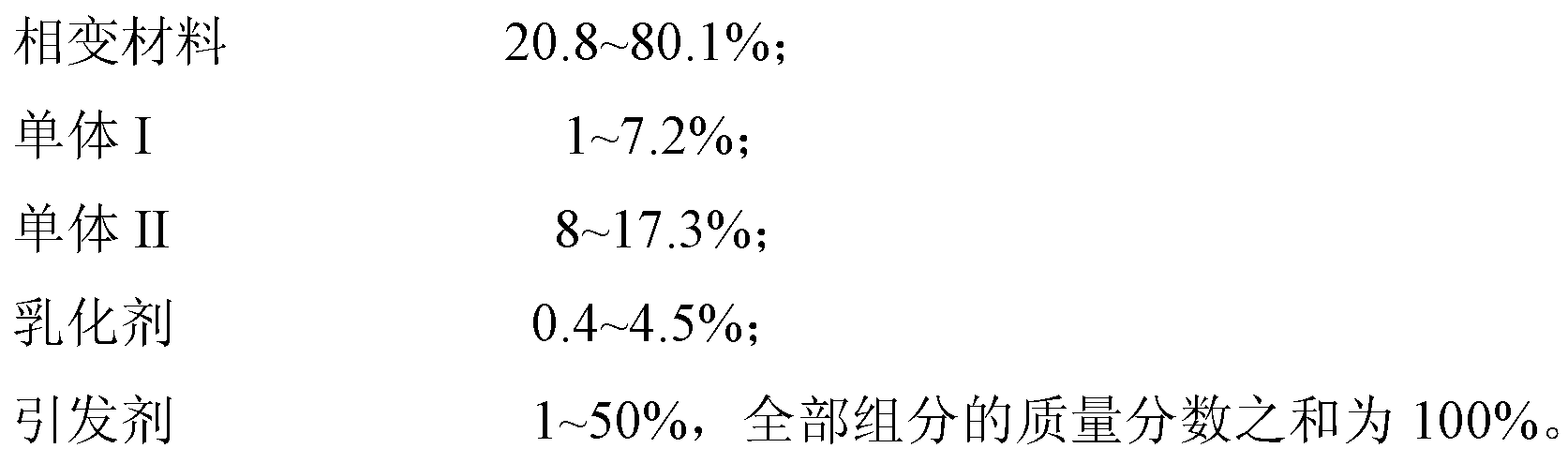

[0033] The present invention simultaneously designs the preparation method (abbreviation preparation method) of phase-change material capsule, and this preparation method adopts the mass composition of capsule described in the present invention and following technology: take polymerized monomer as capsule wall material, take phase-change material as capsule core The mass fraction of the polymerized monomer, phase change material, emulsifier, initiator, and dispersant mixture is mechanically stirred or ultrasonically oscillated at a temperature of 0 to 90 ° C, and the optical microscope or environmental scanning electron microscope is used at any time Observe the particle size of the emulsion droplet in the emulsion until an emulsion with a particle size of 1-1000 microns or below 1 micron is produced, and then under the action of an initiator, the monomer is polymerized by suspension polymerization or in-situ polymerization , maintained at a stirring speed of 100-999r / min for 1...

Embodiment 1

[0046] At 0°C, 1 g of 3-eicosylpyrrole, 17.3 g of pyrrole, 30 g of a saturated aqueous solution of calcium chloride, 49.9 g of ferric bromide, 380 g of chloroform and 10 g of emulsifier polyacrylic acid sodium salt emulsion (solid content 1.8 g) were prepared in 500mW ultrasonic vibration for 1 hour, so that the average diameter of the emulsion droplets reaches 0.7 microns; then stir at 800rpm for 5 hours; stop stirring, and obtain the phase change material nanocapsule emulsion.

[0047] After testing, the average particle diameter of the obtained nanocapsules is 0.9 micron, and the crystallization melting endothermic temperature (T m ) is 29.9°C, the heat of fusion (ΔH m ) is 64J / g, crystallization exothermic temperature (T c ) is 26.1°C, there is no obvious supercooling crystallization phenomenon, and the crystallization enthalpy (ΔH c ) is 65J / g, the mass percent of calcium chloride in the nanocapsule is 30%, and the conductivity of the nanocapsule is 980S / cm.

Embodiment 2

[0049] Under 0 ℃, 3-decyl pyrrole 7.2g, pyrrole 8g, sodium sulfate saturated aqueous solution 31.8g, copper bromide 50g, carbon tetrachloride 300g and emulsifier styrene-maleic anhydride sodium salt emulsion 16g (solid content 3g), oscillating with ultrasonic wave at 500mW for 1 hour, so that the average diameter of the emulsion droplets reaches 0.6 micron; stirring at 800rpm for 5 hours; stopping stirring, to obtain phase change material nanocapsule emulsion.

[0050] After testing, the average particle size of the obtained nanocapsules is 0.8 microns, T m 32.4°C, ΔH m 54J / g, T c 29.1℃, no obvious supercooling crystallization phenomenon, ΔH c 55J / g, the mass percentage of sodium sulfate decahydrate in the nanocapsule is 56%, and the conductivity of the nanocapsule is 870S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com