Microbacterium sp.T3 with tolerance on heavy metals and application thereof

A heavy metal and tolerance technology, applied in the direction of bacteria, water pollutants, water/sludge/sewage treatment, etc., can solve the problem of less bacteria, achieve the effect of strong vitality, many types of metal tolerance, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

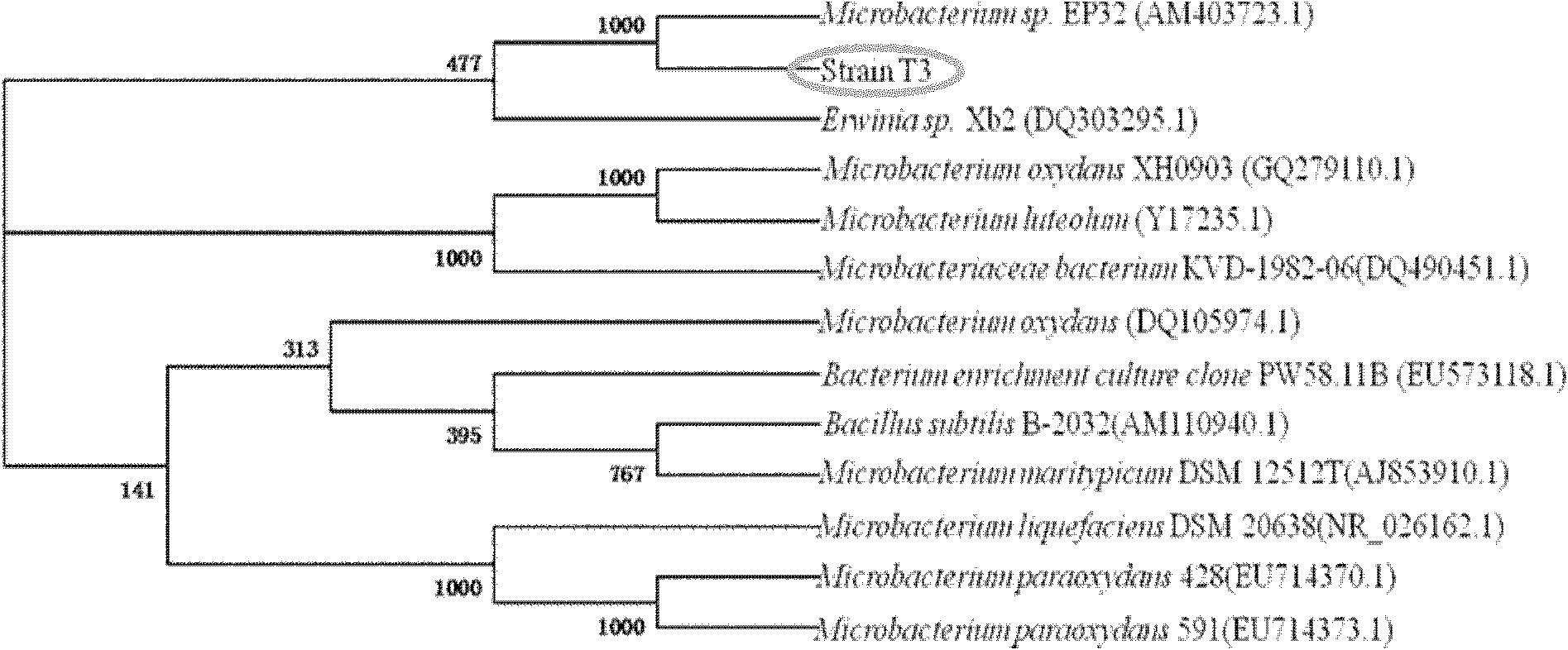

[0033] Example 1: strain morphological characteristics and biological identification

[0034] 1. Morphological characteristics

[0035] Streak inoculate the monoclonal colony into LB solid medium, place the plate upside down in a constant temperature incubator, incubate at 30°C for 1 to 3 days, and observe the colony morphology. Microbacterium sp.T3 round spots, bright yellow, smooth and moist surface, no diffusion, see figure 1 .

[0036] 2. Physiological and biochemical characteristics

[0037] Gram staining, oxidase test, contact enzyme test, bacterial motility test, oxidative fermentation test of sugar alcohols (including glucose, lactose, galactose, fructose, xylose, sucrose, maltose, mannitol), utilization of sugar Alcohol gas production test, methyl red test, V-P test, indole test, nitrate reduction test, H 2 S production test, arginine dihydrolase test, citrate utilization test, urease test, starch hydrolysis, litmus milk test, gelatin liquefaction test, the result...

Embodiment 2

[0042] Example 2: Bacteria to the maximum tolerance concentration of heavy metals

[0043]Prepare solid medium containing heavy metal ions, the concentration starting from 0.1mM / L and increasing by 0.5mM. Streak inoculation on fresh LB solid medium, culture at 30°C for 48h for activation, pick single clone colony and inoculate into LB liquid medium, culture at 30°C, 120r / min shaking for 24h, collect bacterial concentration OD 600 1.5 bacterial solution by 10 0 、10 -1 、10 -2 、10 -3 、10 -4 、10 -5 Proportionally dilute, dip the bacterial solution of each concentration and inoculate it on the heavy metal solid medium. Cultivate at 30°C, observe and record the growth of the bacteria every 24 hours, and the lowest heavy metal concentration that inhibits its obvious growth within 120 hours is the maximum tolerated concentration of the bacteria, as shown in Table 2.

[0044] Table 2

[0045]

Embodiment 3

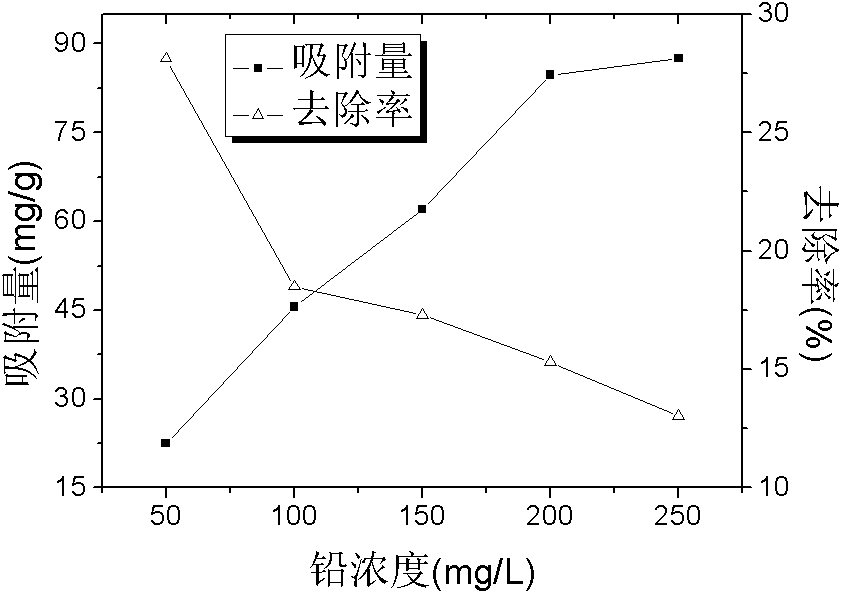

[0046] Embodiment 3: The adsorption effect of adsorbent to lead

[0047] Be respectively 20, 50, 100, 150 and 200mg / L in lead concentration, in the solution that pH value is 6, respectively add and cultivate 12h, the adsorbent that dosage is 0.5g / L is made by the bacterium of the present invention, in Adsorbed at 30°C for 90 minutes, centrifuged to collect the supernatant, and measured the remaining lead ion concentration at adsorption equilibrium. With Pb 2+ The increase in initial mass concentration, Pb 2+ The removal rate decreased, while the equilibrium adsorption capacity increased, but the increase in adsorption capacity became smaller and smaller. The maximum adsorption capacity of biosorbent can reach 87.49mg / g, see image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com