Root apex filling material and preparation method thereof

A filling material and root tip technology, which is applied in the field of preparing hard tissue repair materials, can solve the problems of low cohesion of tooth tissue, long curing time, poor biocompatibility, etc., and achieves simple process, low price and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

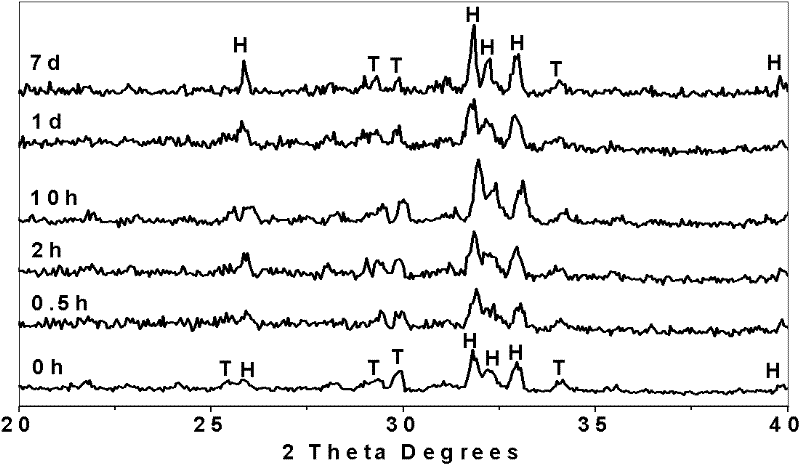

[0045] Example 1 Preparation method of hydroxyapatite / tetracalcium phosphate / polyacrylic acid root tip filling material

[0046] 1) Preparation of the solid phase part: Accurately weigh 0.435 g of natural hydroxyapatite powder, 0.435 g of tetracalcium phosphate (0-50 μm in particle size, 2-8 μm in average particle size), 0.87 g of polyacrylic acid (average molecular weight 50,000), 0.215 grams of citric acid, and 0.215 grams of sodium citrate are fully ground in a mortar, passed through a 200-mesh sieve, stored in a moisture-proof place, and set aside

[0047] 2) Preparation of the liquid phase: 0.2 mL of deionized water;

[0048] 3) The preparation method of hydroxyapatite / tetracalcium phosphate / polyacrylic acid apical filling material: the ambient temperature is 23±1°C, and the solid-liquid phase mass ratio is 5:1. The materials were placed on a clean and dry glass plate, fully mixed with a plastic mixing knife, the mixing time was 60-90 seconds, and the dough-like hydroxya...

Embodiment 2

[0052] Example 2 Anti-scattering detection of hydroxyapatite / tetracalcium phosphate / polyacrylic acid root tip filling material

[0053] According to the method in Example 1, thoroughly mix the hydroxyapatite / tetracalcium phosphate / polyacrylic acid apical filling material according to the appropriate powder-liquid ratio (5:1), mix for 1 minute, and immediately place it in a container containing 10 mL of PBS liquid After standing for 10 minutes, observe the anti-scattering property of the sample. Figure 5 It was shown that the hydroxyapatite / tetracalcium phosphate / polyacrylic acid apical filling material was solidified in PBS solution, and there was no debris around the material, and no disintegration phenomenon was seen, suggesting that the material has good anti-scattering properties.

Embodiment 3

[0054] Example 3 Detection of curing time of hydroxyapatite / tetracalcium phosphate / polyacrylic acid root tip filling material:

[0055] According to the method of Example 1, the hydroxyapatite / tetracalcium phosphate / polyacrylic acid root tip filling material was fully mixed according to the appropriate powder-liquid ratio (mass ratio 5:1), and after mixing for 1 minute, a diameter of 10 mm was placed. In a silicone rubber mold with a height of 2mm, the curing time of the material is measured by the Vicat needle method, that is, a needle with a mass of 300g and a cross-sectional area (d=1mm) is used to allow the needle to slide freely until Until the needle has no obvious indentation, start timing from the time when the solid phase and the liquid phase are mixed, and measure once every 15 seconds. The curing time is the time required from the beginning of self-adjustment to curing. The experimental results show that the curing time of the hydroxyapatite / tetracalcium phosphate / p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com