Method for preparing magnetic chitosan microspheres

A technology for chitosan microspheres and chitosan, which is applied in the field of magnetic chitosan microspheres and their preparation, can solve the problems of unstable process conditions, difficulty in scaling up, and high cost of magnetic chitosan microspheres, and reduces the complexity of The effect of steps, low cost, and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

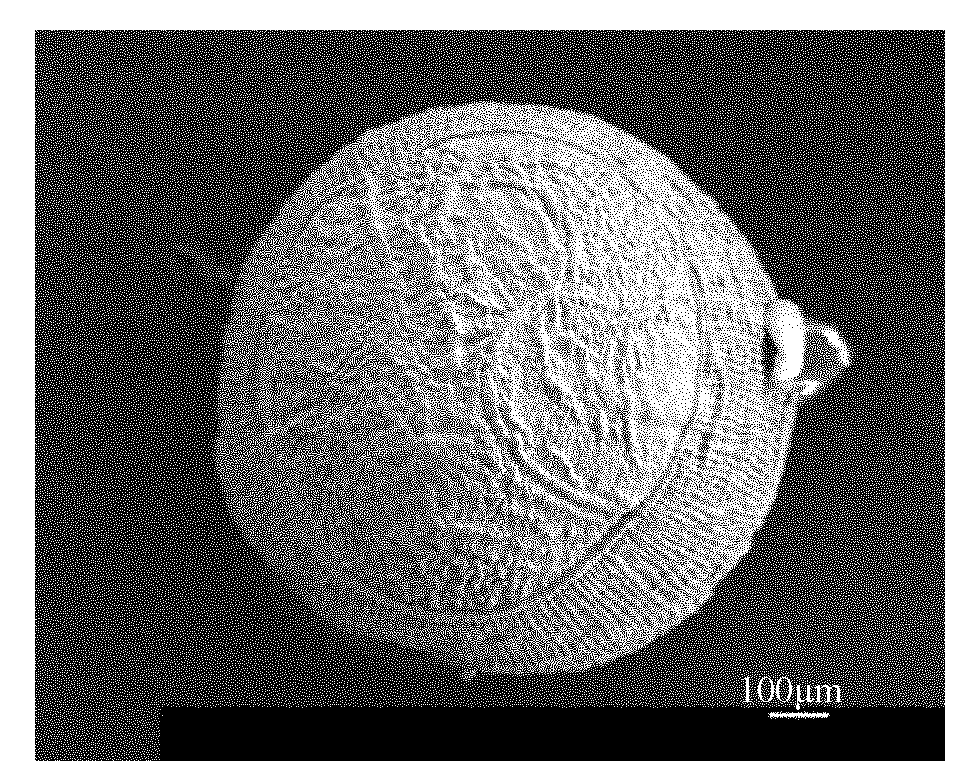

[0024] Accurately weigh 10 g of chitosan, add 2% acetic acid solution to 100 g, and dissolve under stirring. Store in centrifuge. Take 27g of ferric chloride hexahydrate and 9.9g of ferrous chloride tetrahydrate and dissolve them in 100ml of water to form a solution. The prepared chitosan solution and iron ion solution are mixed evenly according to the mass ratio of 1:1. Use a 1ml syringe to absorb the mixed solution and add it dropwise to a 20% ammonia solution, stir, and soak the formed magnetic chitosan microspheres in the lye for 1 hour, wash them in distilled water for 3 times after taking them out, 1 hour each time, and freeze them. Observe under a microscope after drying (see figure 1 ).

Embodiment 2

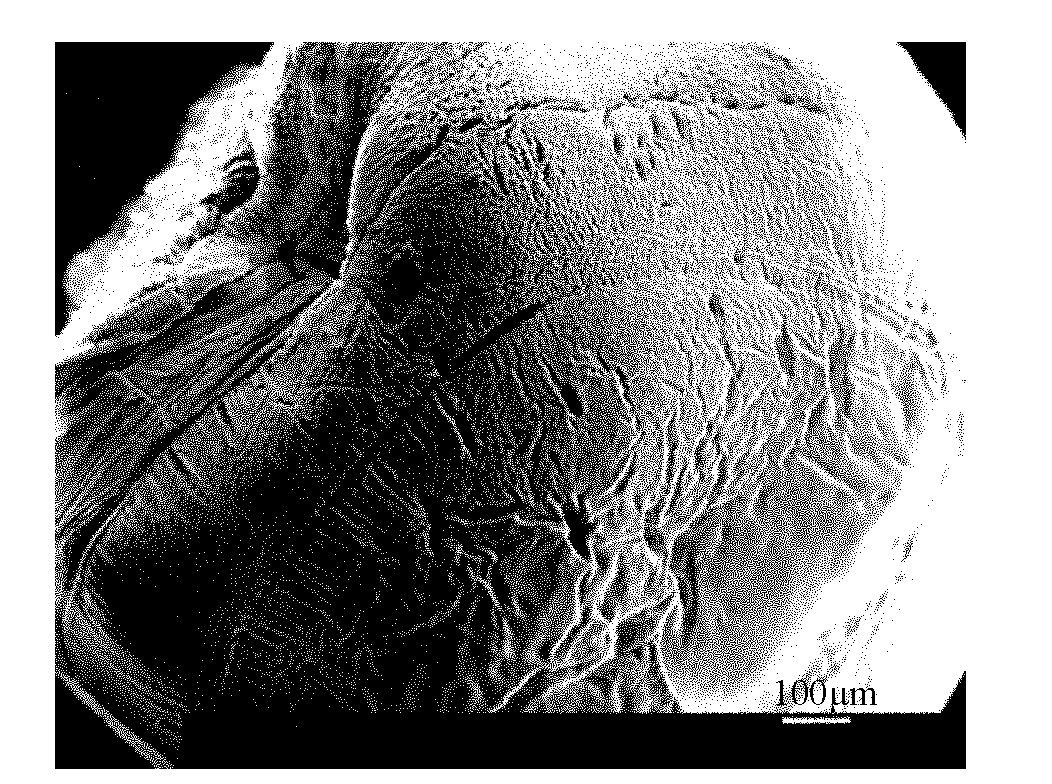

[0026] Accurately weigh 10 g of chitosan, add 2% acetic acid solution to 100 g, and dissolve under stirring. Store in centrifuge. Take 24.2g of ferric nitrate and 9.0g of ferrous nitrate dissolved in 400ml of water to form a solution. The prepared chitosan solution and iron ion solution are mixed evenly according to the mass ratio of 1:1. Draw the mixed solution with a 1ml syringe and add it dropwise in a 25% sodium hydroxide solution, stir, and the formed magnetic chitosan microspheres are soaked in lye for 1 hour, and washed 3 times in distilled water after taking it out, 1 hour each time , observed under a microscope after freeze-drying (see figure 2 ).

Embodiment 3

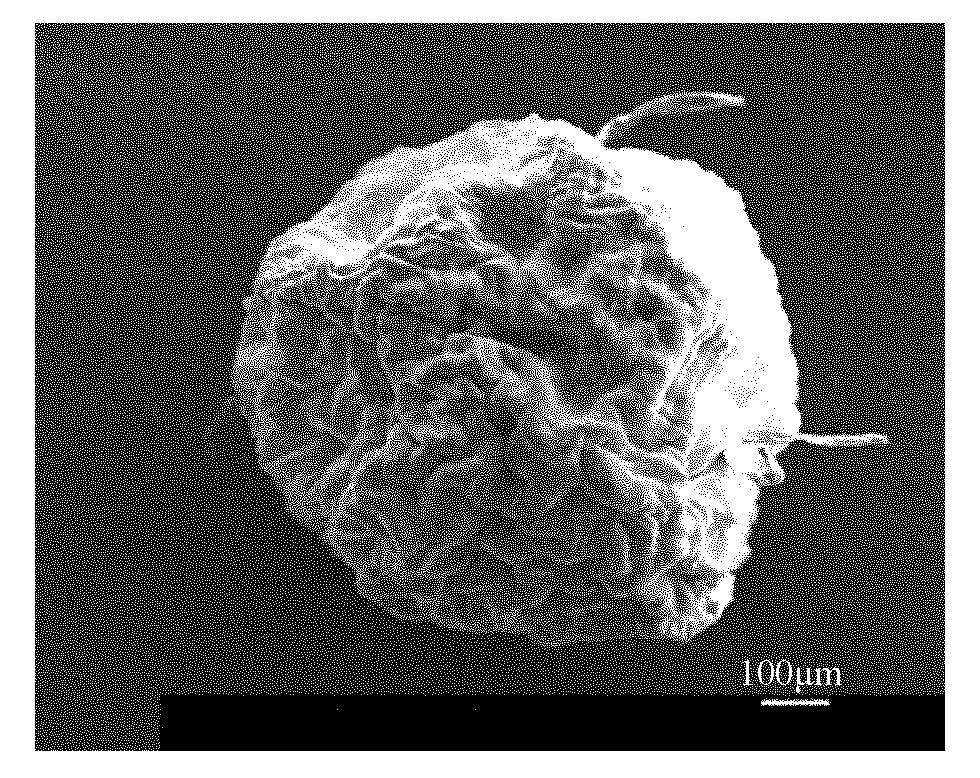

[0028] Accurately weigh 10 g of chitosan, add 2% acetic acid solution to 100 g, and dissolve under stirring. Store in centrifuge. Take 3.44g of ferric sulfate and 0.76g of ferrous sulfate and dissolve it in 100ml of water to form a solution. The prepared chitosan solution and iron ion solution are mixed evenly according to the mass ratio of 1:1. Use a 1ml syringe to absorb the mixed solution and add it dropwise in a 10% lithium hydroxide solution, stir, and the formed magnetic chitosan microspheres are soaked in lye for 1 hour, and washed 3 times in distilled water after taking it out, 1 hour each time , observed under a microscope after freeze-drying (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com