Catalyst for preparing epoxy propane by propylene liquid-phase epoxidation reaction and preparation method thereof

A technology for propylene oxide and catalyst, applied in the unique preparation field of the catalyst, can solve the problems of serious pollution, corrosion of equipment, restricting economic benefits, etc., and achieve the effects of high selectivity, low production cost and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

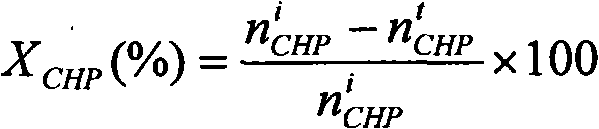

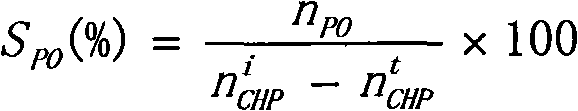

Method used

Image

Examples

Embodiment 1

[0023] Take 2g P 123 , 0.2g of cetyltrimethylammonium bromide (CTAB), 45g of 2M hydrochloric acid and 15g of water were put into a 100ml round bottom flask, and after stirring at 40°C for 6 hours, 5.7g of tetraethyl orthosilicate (TEOS) was added, Continue to stir for 20 hours and move into the reaction kettle, crystallize at 100 ° C for 24 hours, after suction filtration, washing and drying, heat the solid product to reflux in a mixed solution of ethanol and 2M hydrochloric acid for 12 hours, (in the above mixed solution, ethanol The mass ratio with 2M hydrochloric acid is 70:5), and after suction filtration, washing and drying, the SBA-15 carrier after ethanol extraction of the template agent was obtained.

[0024] Get 3g of the SBA-15 carrier after the ethanol extraction template agent is put into the quartz reaction tube that chemical vapor deposition (CVD) uses, heat to 700 ℃, with the N of 150ml / min 2 As the carrier gas, put TiCl 4 Steam is brought into the SBA-15 bed ...

Embodiment 2

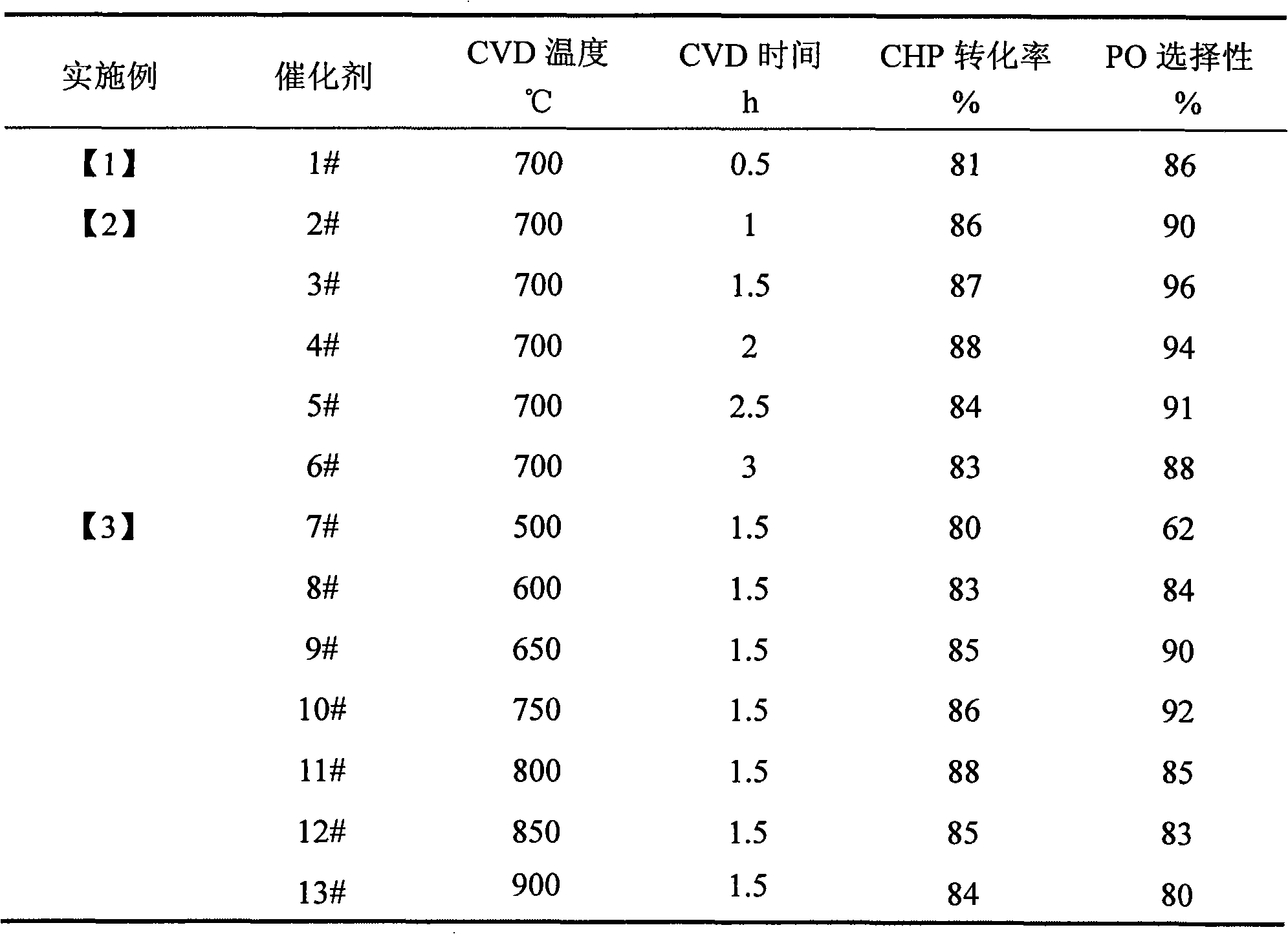

[0026] The chemical vapor deposition time in Example 1 was changed to 1.0, 1.5, 2.0, 2.5, and 3.0 hours to obtain catalysts 2# to 6#. See Table 1 for catalyst performance evaluation.

Embodiment 3

[0028] Change the chemical vapor deposition time in Example 1 to 1.5 hours, and change the chemical vapor deposition temperature to 500, 600, 650, 750, 800, 850, and 900°C to obtain 7# to 13# catalysts. The catalyst performance evaluation is shown in Table 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com