Ultrasonic harmless recycling technology and equipment for sewage of farm

A resourceful, farm-based technology, applied in the field of environmental pollution control, can solve the problems of uncertain income and high risk, difficult discharge of high-concentration sewage, pollution of the surrounding environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

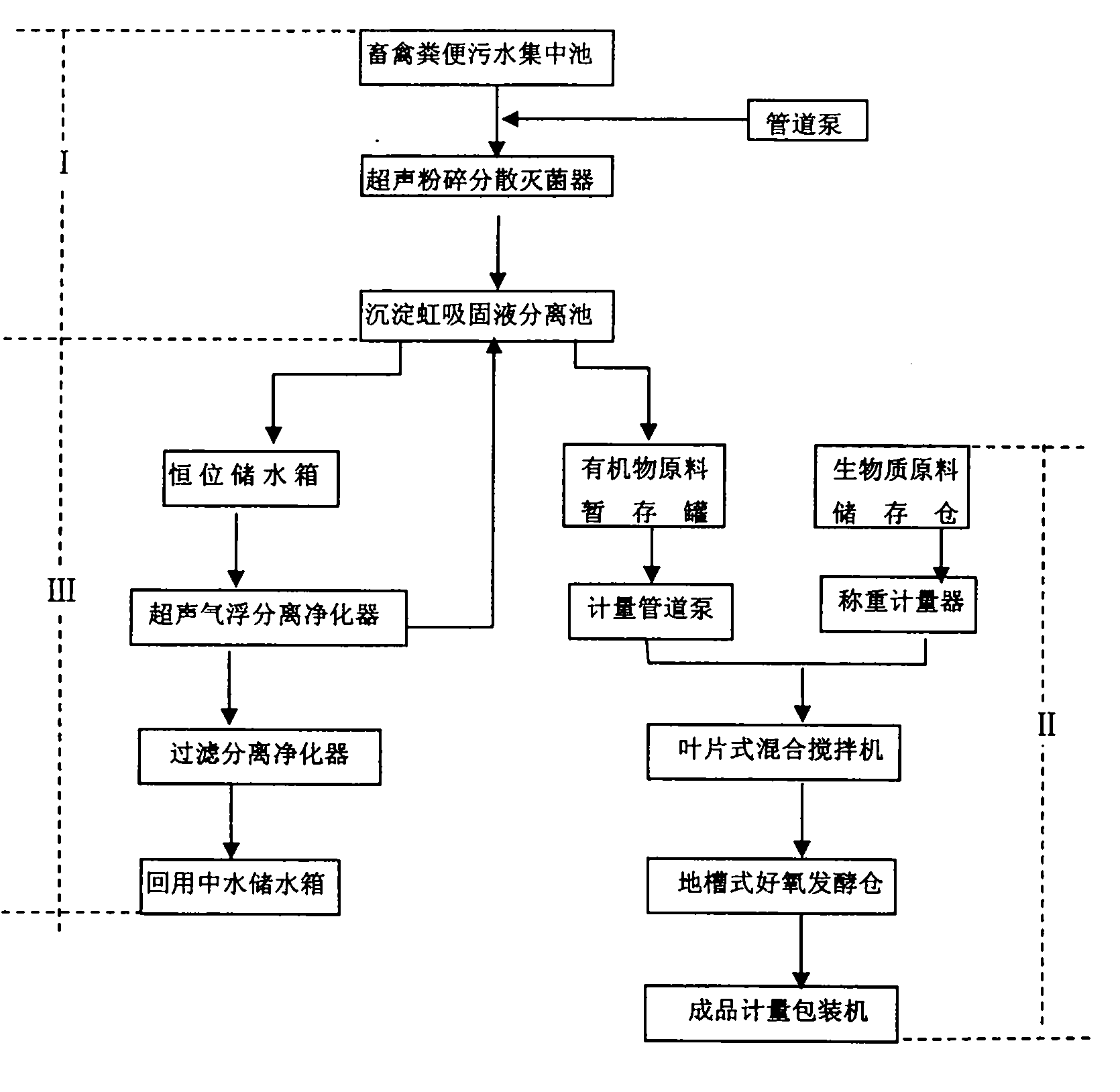

[0070] as attached figure 1 As shown, the ultrasonic harmless and resourceful treatment technology and equipment of farm sewage of the present invention include ultrasonic crushing, sterilization and separation pretreatment (I), biological aerobic fermentation fertilizer (II), and ultrasonic separation and purification (III). A relatively independent process technology operation unit, and its supporting special technical equipment and process technical parameters.

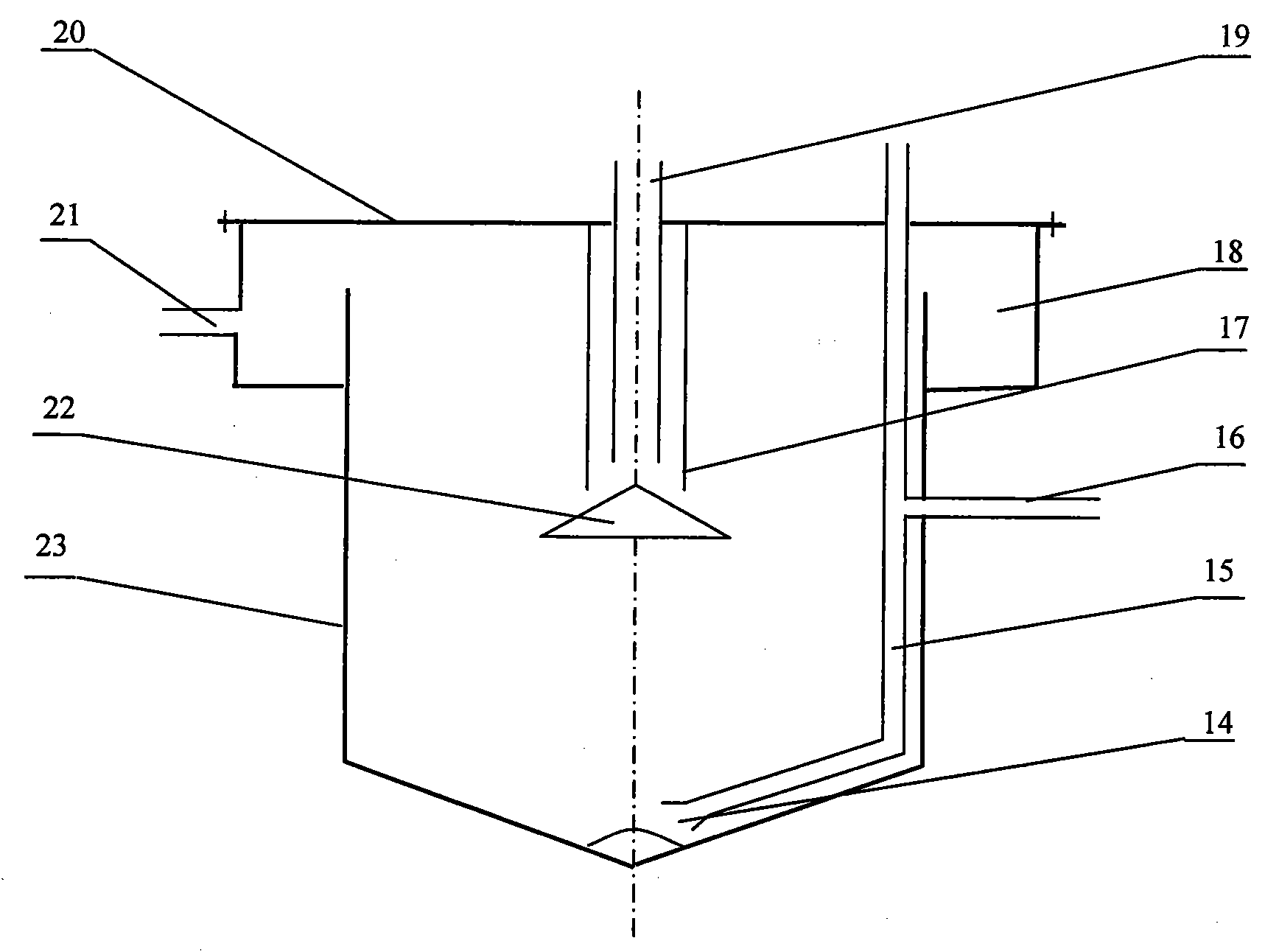

[0071] The ultrasonic pulverization sterilization separation pretreatment (I) process technology operation unit includes a livestock and poultry feces sewage concentration pool, an ultrasonic pulverization dispersion sterilizer, and a sedimentation siphon solid-liquid separation pool.

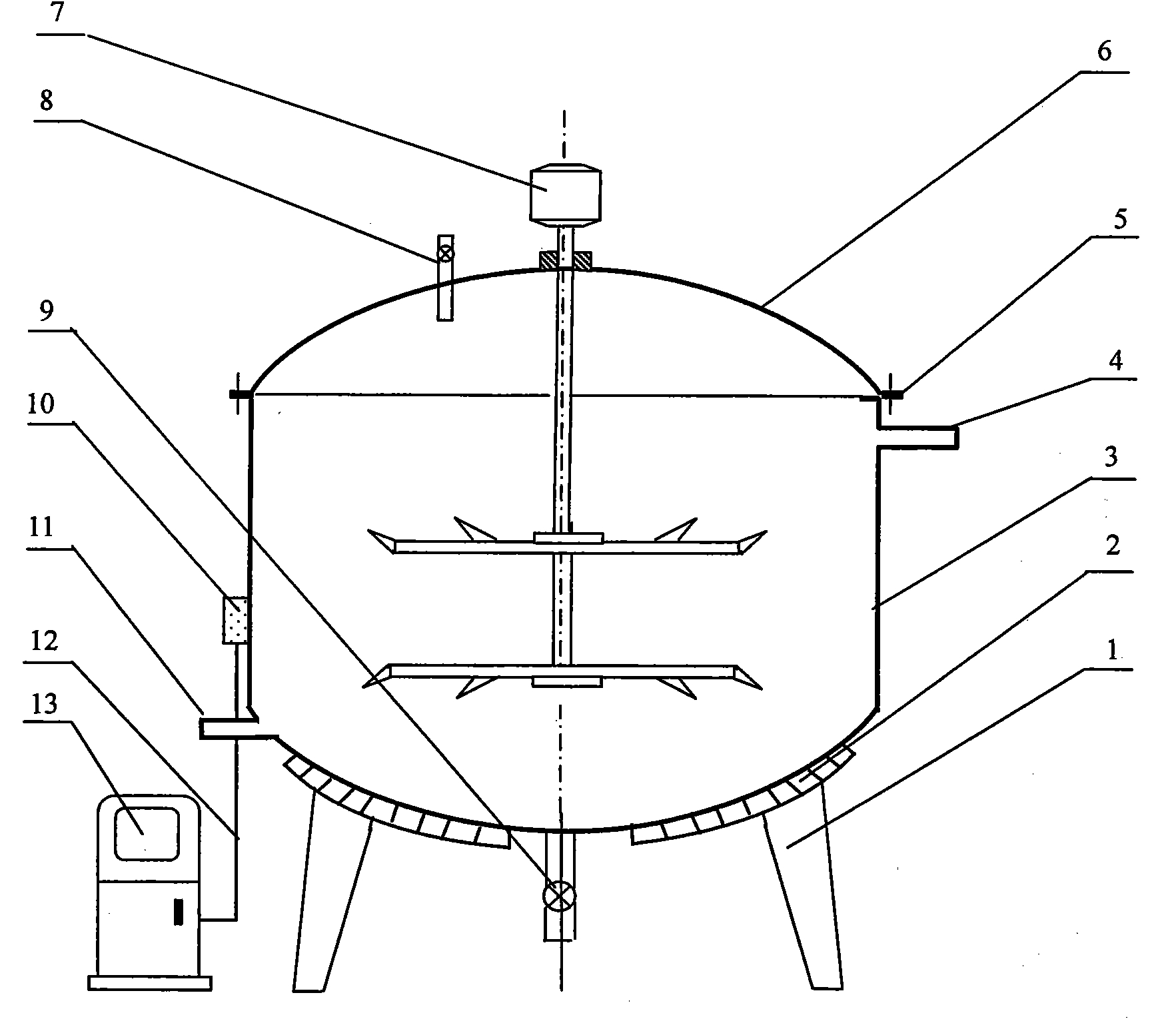

[0072] The sewage concentration pool for livestock and poultry manure is designed as a fully enclosed rectangular pool structure with a triangular bottom, equipped with an auger, and equipped with a metering pipeline pump on the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com