Aqueous emulsion composition, and emulsion resin prepared by using same and use thereof

A water-based emulsion and composition technology, applied in the direction of ester copolymer adhesives, adhesive types, coatings, etc., can solve the problems of poor stain resistance, dry film elasticity and low temperature flexibility, and easy dusting, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

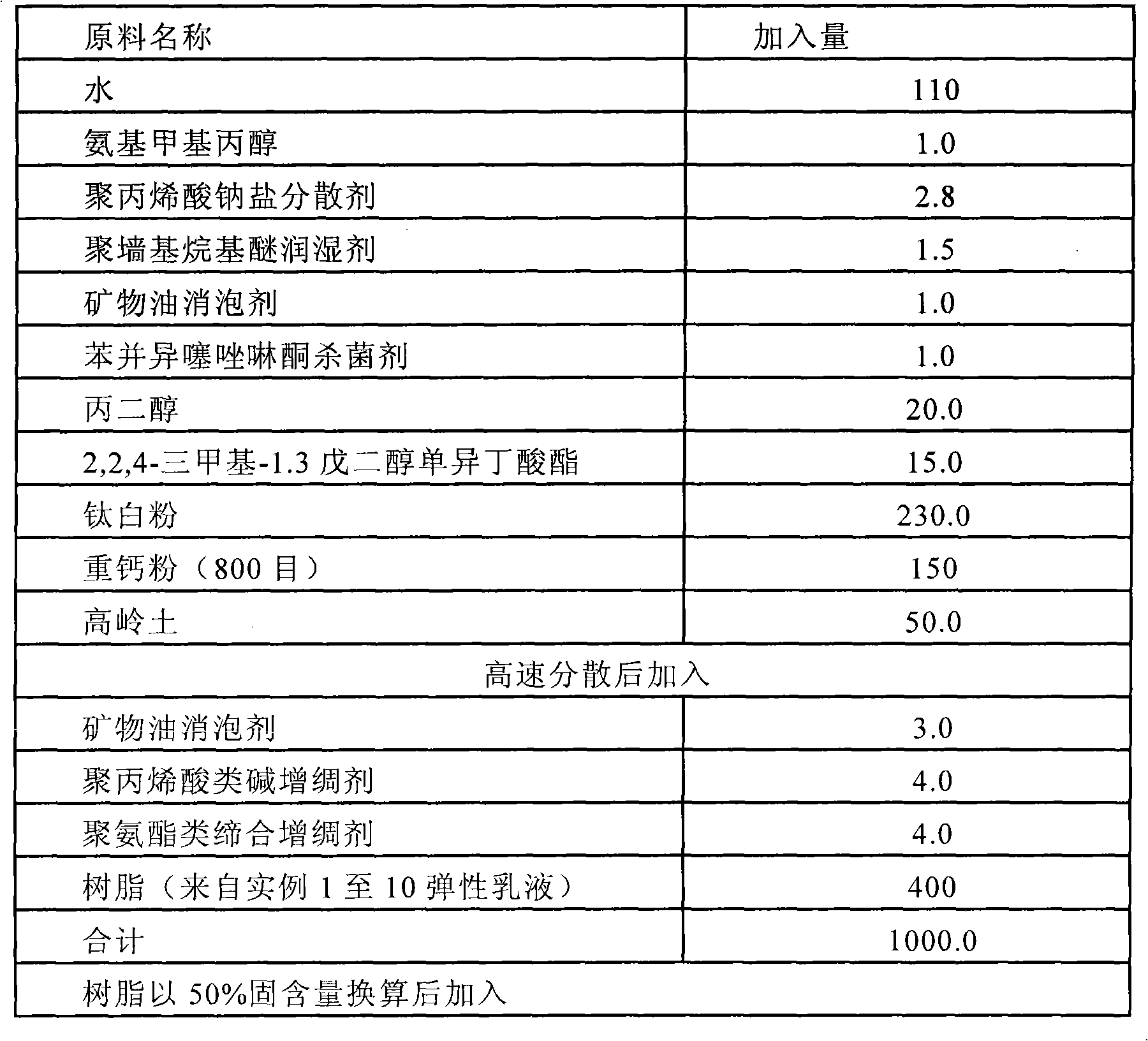

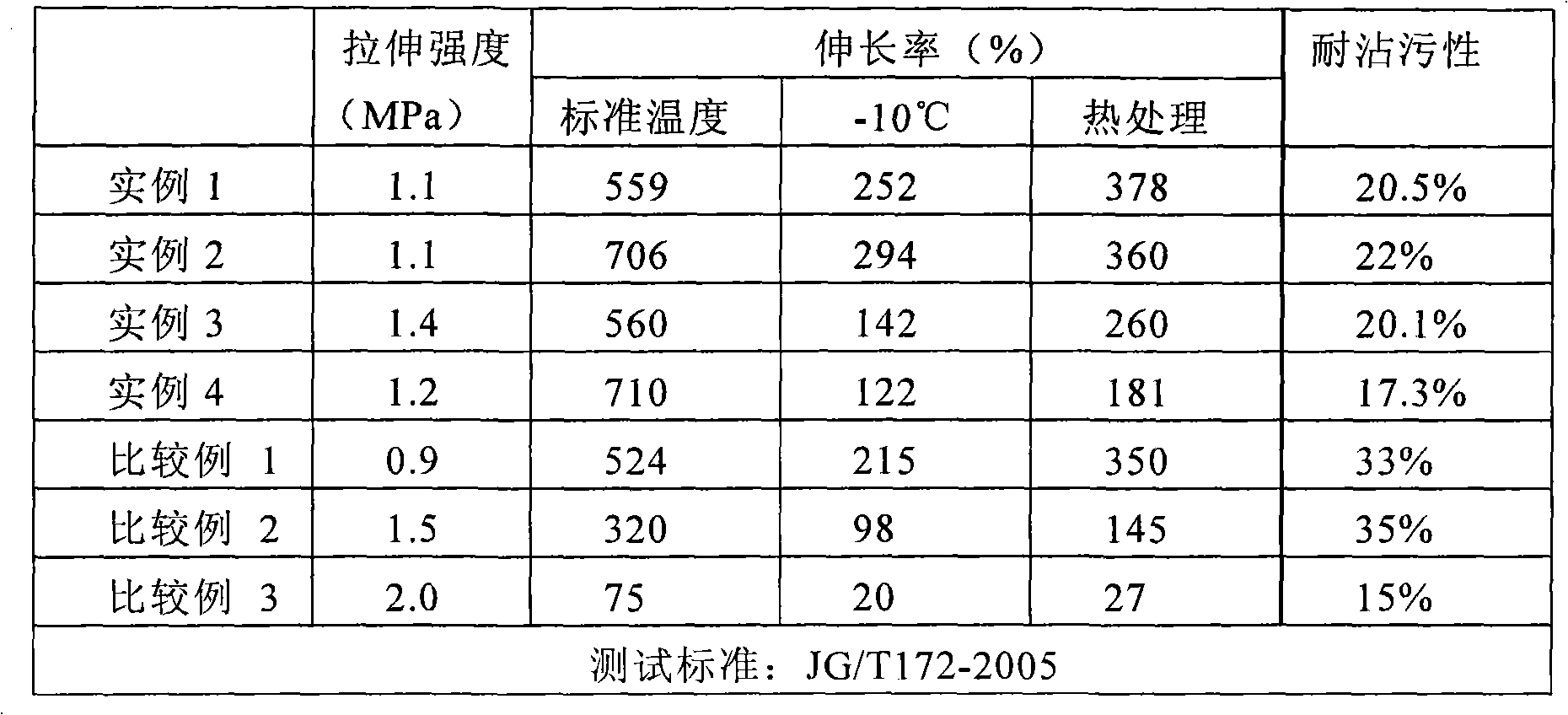

Examples

example 1

[0030] Water-based emulsion composition: 485 grams of butyl acrylate, 95 grams of acrylonitrile, 5 grams of N-methylol acrylamide, 2.9 grams of ethylene glycol diacrylate, 6.8 grams of acrylic acid, 1 gram of sodium bicarbonate, nonylphenol polyoxygen 5 grams of ammonium vinyl ether sulfate, 9 grams of lauryl-tetradecyl polyoxyethylene ether, 4.5 grams of fatty alcohol sodium succinate, 1.5 grams of ammonium persulfate, 415 grams of water, 4 grams of ammonia water, 4.5 grams of benzophenone, 9 grams of acrylate containing tertiary amino groups (6410 (manufactured by Changxing Chemical Industry))

[0031] Preparation method: 485 grams of butyl acrylate, 95 grams of acrylonitrile, 5 grams of N-methylol acrylamide, 2.9 grams of ethylene glycol diacrylate, 6.8 grams of acrylic acid, 5 grams of nonylphenol polyoxyethylene ether ammonium sulfate, 9 grams of lauryl-tetradecyl polyoxyethylene ether, 3.5 grams of fatty alcohol sodium succinate and 195 grams of water were mixed and stir...

example 2

[0033] Water-based emulsion composition: 490 grams of butyl acrylate, 88 grams of acrylonitrile, 9 grams of N-methylol acrylamide, 1.9 grams of ethylene glycol diacrylate, 5.8 grams of methacrylic acid, 1 gram of sodium bicarbonate, allyl Alkyl polyoxyethylene ether ammonium sulfate 5 grams, octylphenol polyoxyethylene ether 9 grams, sodium dodecylbenzene sulfonate 4.5 grams, ammonium persulfate 1.5 grams, water 415 grams, ammonia water 4 grams, benzophenone 2.2 grams, 4.5 grams of acrylate containing tertiary amino groups (6410 (manufactured by Changxing Chemical))

[0034] Preparation method: 490 grams of butyl acrylate, 88 grams of acrylonitrile, 9 grams of N-methylol acrylamide, 1.9 grams of ethylene glycol diacrylate, 5.8 grams of methacrylic acid, 5 grams of allyl alkyl polyoxyethylene Ammonium ether sulfate, 9 grams of octylphenol polyoxyethylene ether, 3.5 grams of sodium dodecylbenzenesulfonate and 195 grams of water were mixed and stirred at high speed to prepare a m...

example 3

[0036] Aqueous emulsion composition: 350 grams of butyl acrylate, 133.3 grams of acrylonitrile, 5.8 grams of N-methylolacrylamide, 2.1 grams of ethylene glycol diacrylate, 4.8 grams of acrylic acid, 0.8 grams of sodium bicarbonate, allyl nonyl 3.5 grams of phenol polyoxyethylene ether ammonium sulfate, 7.1 grams of lauryl-tetradecyl polyoxyethylene ether, 8.5 grams of sodium fatty alcohol polyoxyethylene ether sulfosuccinate, 1.5 grams of ammonium persulfate, 472 grams of water, 4 grams of ammonia water grams, 2.2 grams of benzophenone, 4.5 grams of acrylate (6410 (manufactured by Changxing Chemical)) containing tertiary amino groups

[0037] Preparation method: 350 grams of butyl acrylate, 133.3 grams of acrylonitrile, 5.8 grams of N-methylol acrylamide, 2.1 grams of ethylene glycol diacrylate, 4.8 grams of acrylic acid, 3.5 grams of allyl nonylphenol polyoxyethylene ether Ammonium sulfate, 7.1 grams of lauryl-tetradecyl polyoxyethylene ether, 7.5 grams of sodium fatty alcoho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com