Silicate coating-containing absorbable medical magnesium-based metal and preparation method and application thereof

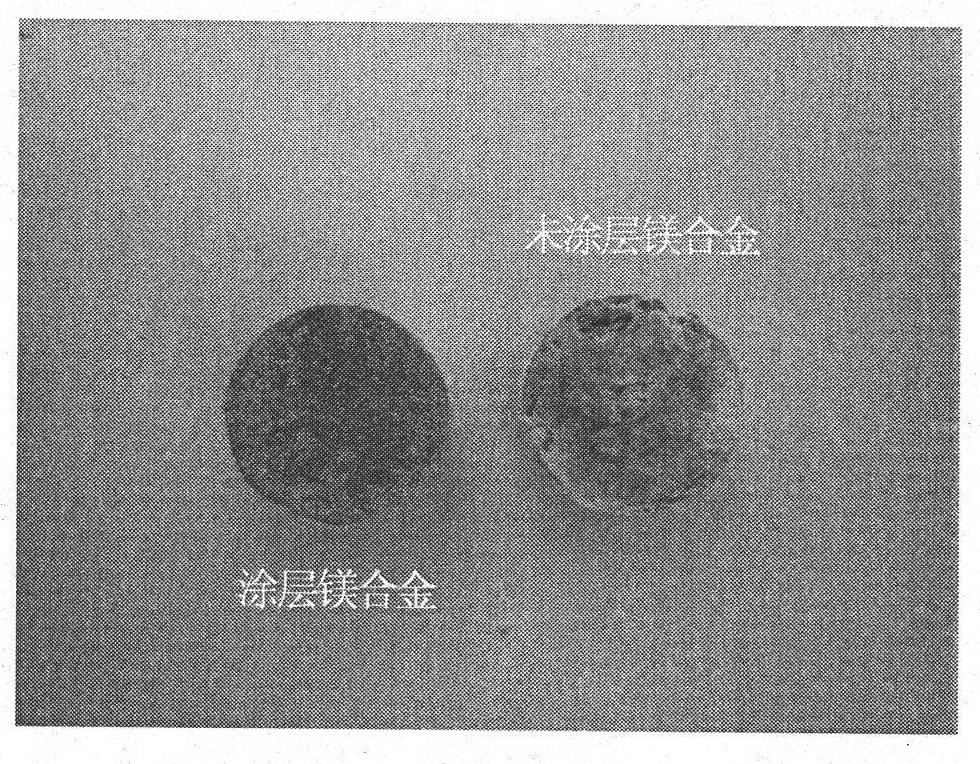

A magnesium-based metal and silicate technology, which is used in the fields of plastic and cosmetic medical devices, biomedical devices, repair and reconstruction surgery, and bone trauma surgery. It can solve the problems of fast degradation and low surface bioactivity, and reduce the degradation speed , degradation rate and biological activity improvement, coating smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

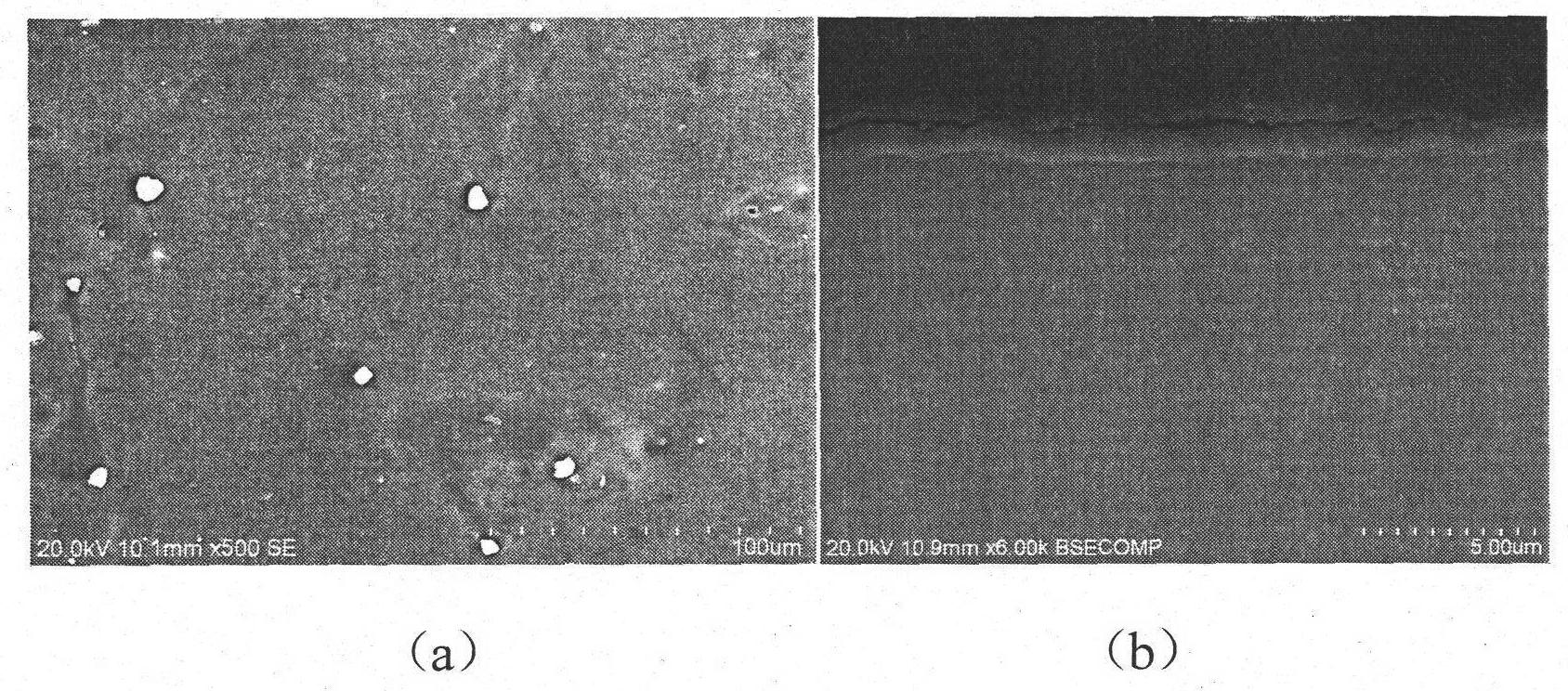

[0041] Taking AZ31B (magnesium-aluminum series) magnesium alloy as the research object, the magnesium alloy was cut into Φ10×5mm samples, and finely ground with 1000# and 2000# metallographic sandpaper respectively to remove the oxide film and other impurities on the surface of the magnesium alloy . After degreasing and surface activation treatment, the magnesium alloy is ready for use.

[0042] The chemical composition and formula of the process liquid of the surface activation treatment are as follows: in the aqueous solution consisting of 200ml of glacial acetic acid, 170ml of distilled water, 8ml of nitric acid, and 0.5g of oxalic acid, the treatment temperature is room temperature, and the treatment time is 20 seconds.

[0043] Rinse the magnesium alloy after the above treatment with tap water, distilled water, absolute ethanol and distilled water in sequence, blow dry, and set aside.

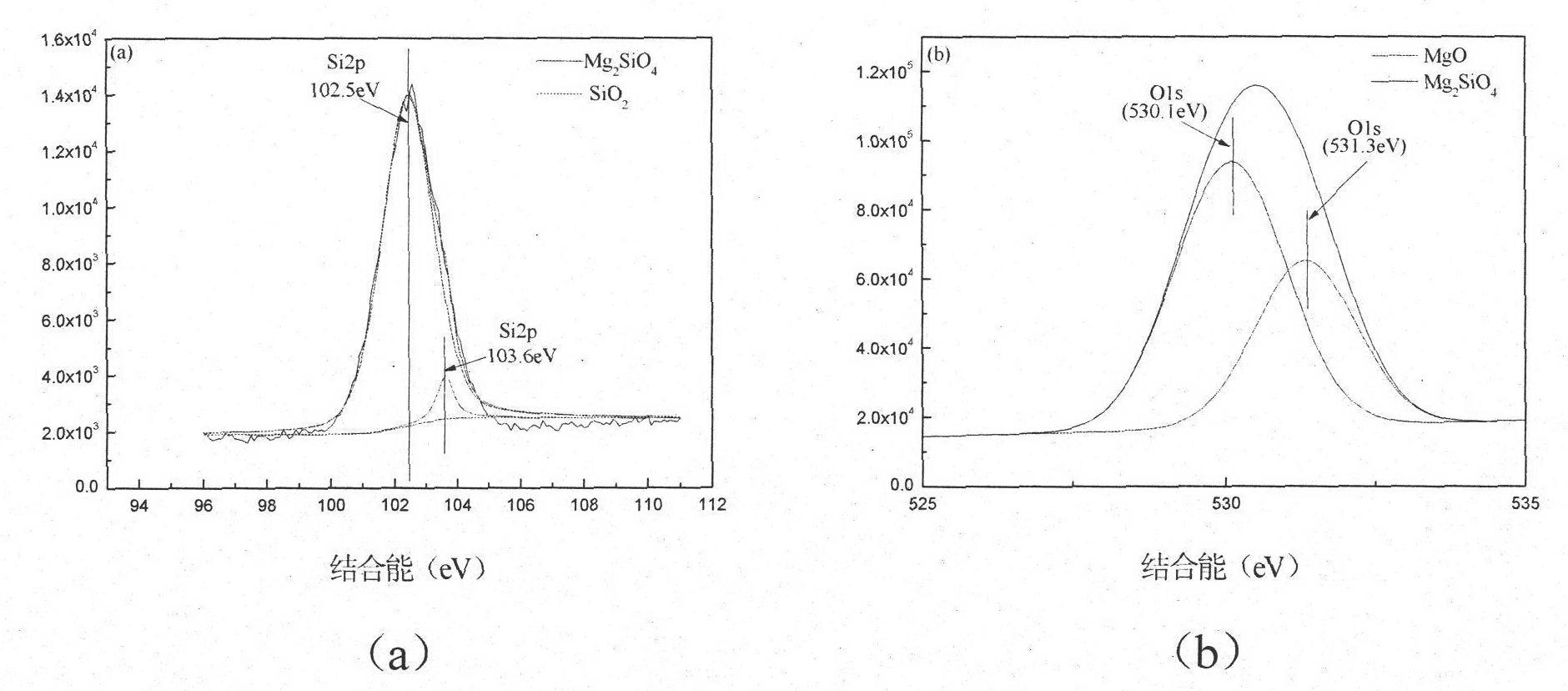

[0044] The composite treatment solution is an alkaline aqueous solution containing si...

Embodiment 2

[0049] Taking ZK60 (magnesium-zinc-zirconium) magnesium alloy as the research object, the magnesium alloy is cut into Φ10×5mm samples, and finely ground with 1000# and 2000# metallographic sandpaper respectively to remove the oxide film and others on the surface of the magnesium alloy. Impurities. After degreasing and surface activation treatment, the magnesium alloy is ready for use.

[0050] The chemical composition and formula of the process treatment solution of the surface activation treatment are as follows: 300ml of glacial acetic acid, 200ml of distilled water, 15ml of nitric acid, 3g of oxalic acid in an aqueous solution, the treatment temperature is room temperature, and the treatment time is 30 seconds.

[0051] Rinse the magnesium alloy after the above treatment with tap water, distilled water, absolute ethanol and distilled water in sequence, blow dry, and set aside.

[0052] The composite treatment solution is an alkaline aqueous solution containing silicate, an...

Embodiment 3

[0056] Taking AZ31B (magnesium-aluminum series) magnesium alloy as the research object, the magnesium alloy was cut into Φ10×5mm samples, and finely ground with 1000# and 2000# metallographic sandpaper respectively to remove the oxide film and other impurities on the surface of the magnesium alloy . After degreasing and surface activation treatment, the magnesium alloy is ready for use.

[0057] The chemical composition and formula of the process treatment solution of the surface activation treatment are as follows: 100ml of glacial acetic acid, 300ml of distilled water, 30ml of nitric acid, and 8g of oxalic acid are carried out in an aqueous solution, the treatment temperature is room temperature, and the treatment time is 20 seconds.

[0058] Rinse the magnesium alloy after the above treatment with tap water, distilled water, absolute ethanol and distilled water in sequence, blow dry, and set aside.

[0059] The composite treatment solution is an alkaline aqueous solution c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com