Methane-carbon dioxide reforming reactive catalyst and preparation method thereof

A carbon dioxide, reforming reaction technology, used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as catalyst deactivation, and achieve anti-carbon performance. Good and excellent catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

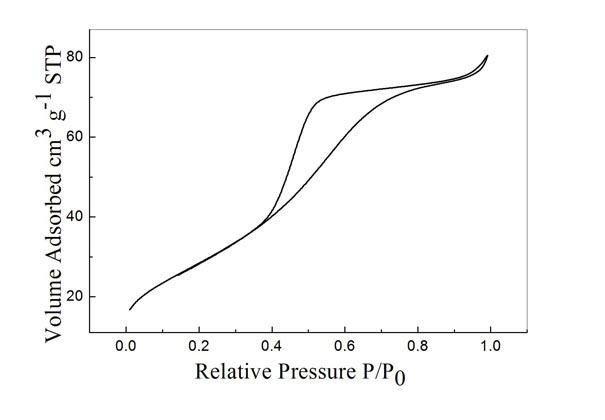

Image

Examples

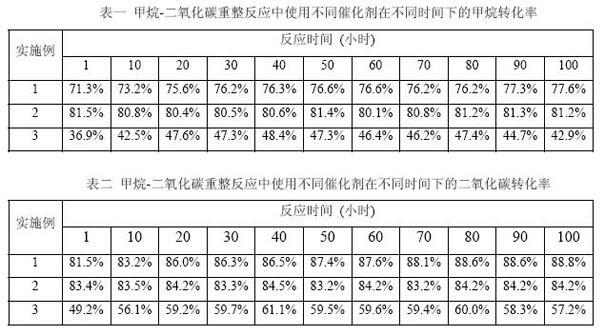

Embodiment 1

[0034] Dissolve 5 grams of P123 in 250 ml of deionized water, add 0.01 mol of nickel nitrate and lanthanum nitrate, and 0.05 mol of zirconium oxynitrate to prepare solution A; prepare 0.1 mol / liter potassium hydroxide aqueous solution, and record it as solution B. Slowly drop solution A and solution B into a large beaker under stirring in a water bath at 40°C, stir evenly to form a green precipitate, continue stirring for 5 hours, wash with deionized water, filter with suction, and leave the obtained filter cake to age for 5 hours . Add 300 ml of 0.1 mol / L sodium hydroxide solution, reflux and age for 48 hours, then filter with suction, dry at 110°C for 24 hours, and roast at 400°C for 4 hours to obtain the required 0.2NiO-0.1La 2 o 3 -ZrO 2 catalyst. This catalyst is used for methane-carbon dioxide reforming reaction: take by weighing 0.2 gram of catalyst sample, at first in H 2 20% H by volume 2 / N 2 Reduction at 500°C for 2 hours in a mixed gas, and then in N 2 Turn ...

Embodiment 2

[0036] Dissolve 5 grams of P123 in 250 ml of deionized water, add 0.01 mol of nickel nitrate and calcium nitrate, and 0.05 mol of zirconium nitrate to prepare solution A; prepare 0.1 mol / liter sodium hydroxide aqueous solution, and record it as solution B. Slowly drop solution A and solution B into a large beaker under stirring in a water bath at 40°C, stir evenly to form a green precipitate, continue stirring for 2 hours, wash with deionized water, filter with suction, and leave the obtained filter cake to age for 12 hours . Add 300 ml of deionized water, reflux and age for 48 hours, then filter with suction, dry at 110°C for 24 hours, and roast at 600°C for 5 hours to obtain the required 0.2NiO-0.2CaO-ZrO 2 catalyst. This catalyst is used for methane-carbon dioxide reforming reaction: take by weighing 0.1 gram of catalyst sample, at first in H 2 30% H by volume 2 / N 2 Reduction at 600°C for 1 hour in a mixed gas, and then in N 2 Turn off the N after heating up to 800°C ...

Embodiment 3

[0038] Dissolve 5 grams of P123 in 250 ml of deionized water, add 0.01 mol of cobalt nitrate and magnesium nitrate, and 0.05 mol of zirconium nitrate to prepare solution A; prepare an ammonia solution with a mass fraction of 20%, and record it as solution B. Slowly drip solution A and solution B into a large beaker under stirring in a water bath at 40°C, stir evenly to form a green precipitate, and continue stirring for 12 hours, then wash with deionized water, filter with suction, and leave the obtained filter cake to age for 12 hours . Add 300 ml of ammonia solution with a mass fraction of 20%, reflux and age for 12 hours, then filter with suction, dry at 110°C for 24 hours, and roast at 500°C for 7 hours to obtain the required 0.2CoO-0.2MgO-ZrO 2 catalyst. This catalyst is used for methane-carbon dioxide reforming reaction: take by weighing 0.1 gram of catalyst sample, at first in H 2 10% H by volume 2 / N 2 Reduction at 600°C for 1 hour in the mixed gas, and N 2 After ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com