Gold nanorod-graphene composite membrane and preparation method thereof

A graphene composite and gold nanorod technology, which is applied in the field of composite membranes, can solve problems such as difficult to control the shape of nano-gold particles, and achieve the effects of good absorption characteristics, simple process, and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the preparation of graphene oxide aqueous solution

[0025] Weigh 5g of natural graphite and 5g of sodium nitrate, mix evenly with 230ml of concentrated sulfuric acid in an ice bath, slowly add 30g of KMnO 4 , to be KMnO 4 After fully mixing with the solution, transfer the above solution to a water bath at 35±5°C for 1 hour, and the solution will become viscous at this time. Slowly add 400ml of pure water, and raise the temperature to 90±5°C to continue the reaction for 30min, the mixture turns from brown to bright yellow. Finally, add 100ml of pure water to dilute, and add 30ml of 30% H 2 o 2 Solution processing to neutralize unreacted KMnO 4 , After the above solution was cooled to room temperature, it was suction filtered and the filter cake was washed repeatedly, and graphite oxide was obtained after vacuum drying. Weigh a certain amount of graphite oxide and disperse it in water, and ultrasonicate for a certain period of time until it is complete...

Embodiment 2

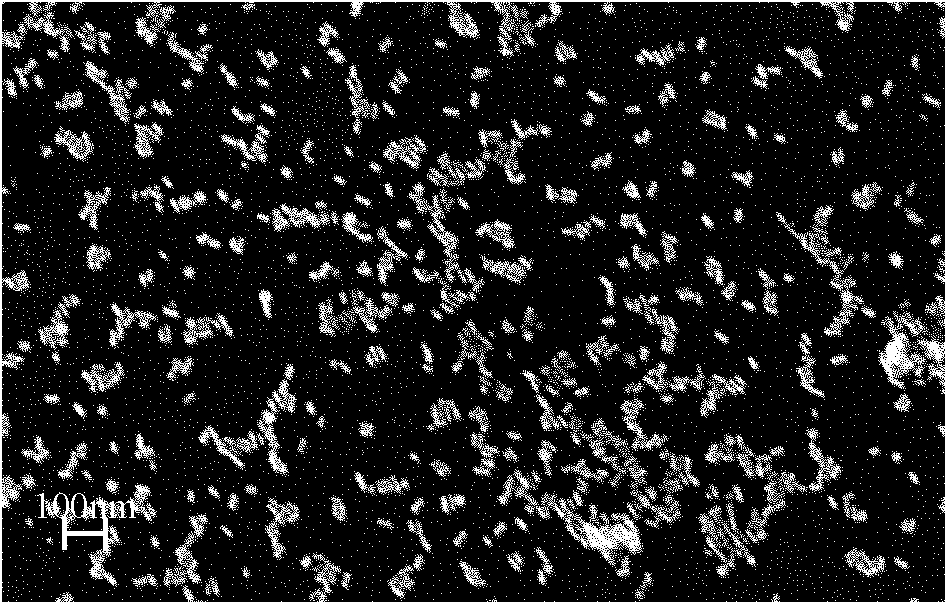

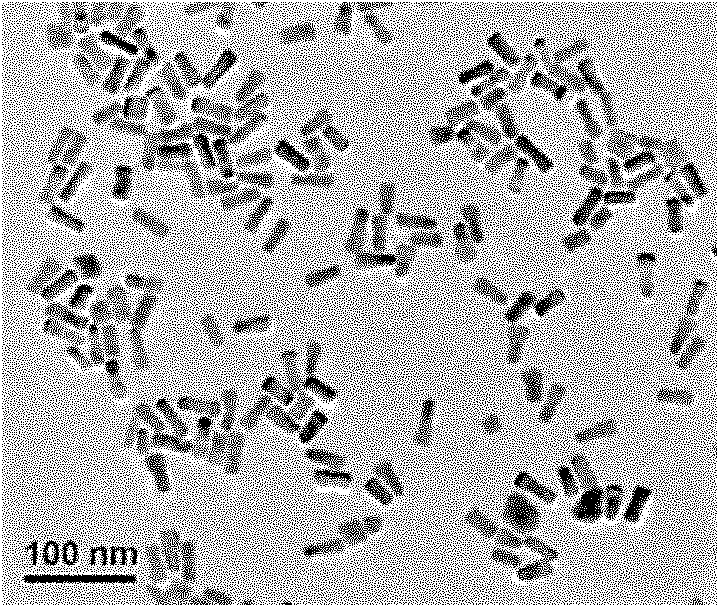

[0026] Embodiment 2: Preparation of gold nanorod aqueous solution

[0027] The preparation of gold nanorods adopts the seed method, which is divided into two steps:

[0028] Prepare seed solution: mix 7.5 ml, 0.01 M CTAB and 0.25 ml, 0.01 M HAuCl 4 Mix well, then add 0.6ml of freshly prepared 0.01M ice NaBH 4 , stir quickly for 2 minutes, then place in a 25-degree water bath to rest for at least 2 hours.

[0029] Prepare the resulting solution: add 4.75ml, 0.01M CTAB, 0.2ml, 0.01M HAuCl in sequence 4 and 0.03ml, 0.01M AgNO 3 , stir to mix thoroughly. Then 0.032ml of 0.1M vitamin C was added, and the solution immediately became colorless. Finally, 20 μl of seed solution was added, stirred rapidly for 10 seconds, and left to stand in a 25-degree water bath for more than 3 hours. The obtained solution was centrifuged at 8500 rpm for 25-30 minutes, the supernatant was poured off, and the precipitate was gold nanorods, which were dispersed in water to obtain an aqueous soluti...

Embodiment 3

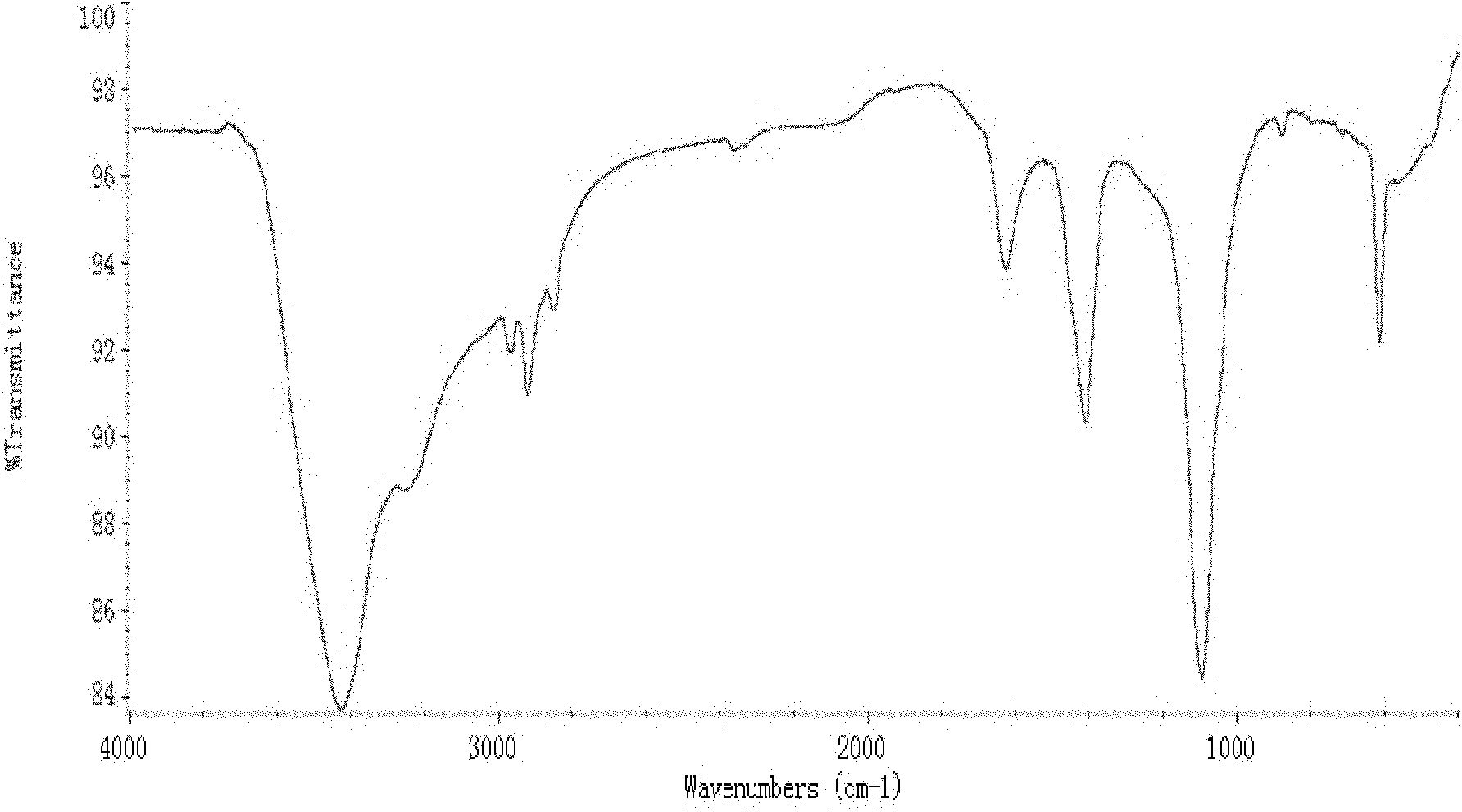

[0031] Embodiment 3: the preparation of oleylamine modified graphene toluene solution microwave heating method

[0032] Weigh about 200 mg of graphite oxide described in Example 1 and dissolve it in 10 ml of oleylamine. The graphite oxide is fully exfoliated into graphene oxide and dispersed evenly in oleylamine by ultrasound. The above homogeneous solution was transferred to a quartz reaction bottle, a stirrer was added, a few drops of concentrated sulfuric acid was added dropwise, and the cap was sealed, and then reacted at 140°C for 3 hours using a microwave synthesizer (Shanghai Zhizhun Scientific Instrument Co., Ltd.). After the reaction system is naturally cooled to room temperature, open the bottle cap. The obtained black solid is first collected by washing and centrifuging with ethanol with a small amount of ammonia water, and then washing and centrifuging with ethanol twice to collect the precipitate. After vacuum drying, oleylamine-modified graphite can be obtained. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com