Antiblocking agent for macroelement water-dissolvable fertilizer, as well as preparation and application of the antiblocking agent

An anti-caking agent and fertilizer technology, applied in the direction of application, fertilizer mixture, fertilization device, etc., can solve the problems of difficult degradation of organic compounds, complicated adding process, soil pollution, etc., achieve good anti-caking effect, broad application prospects, Prepare simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

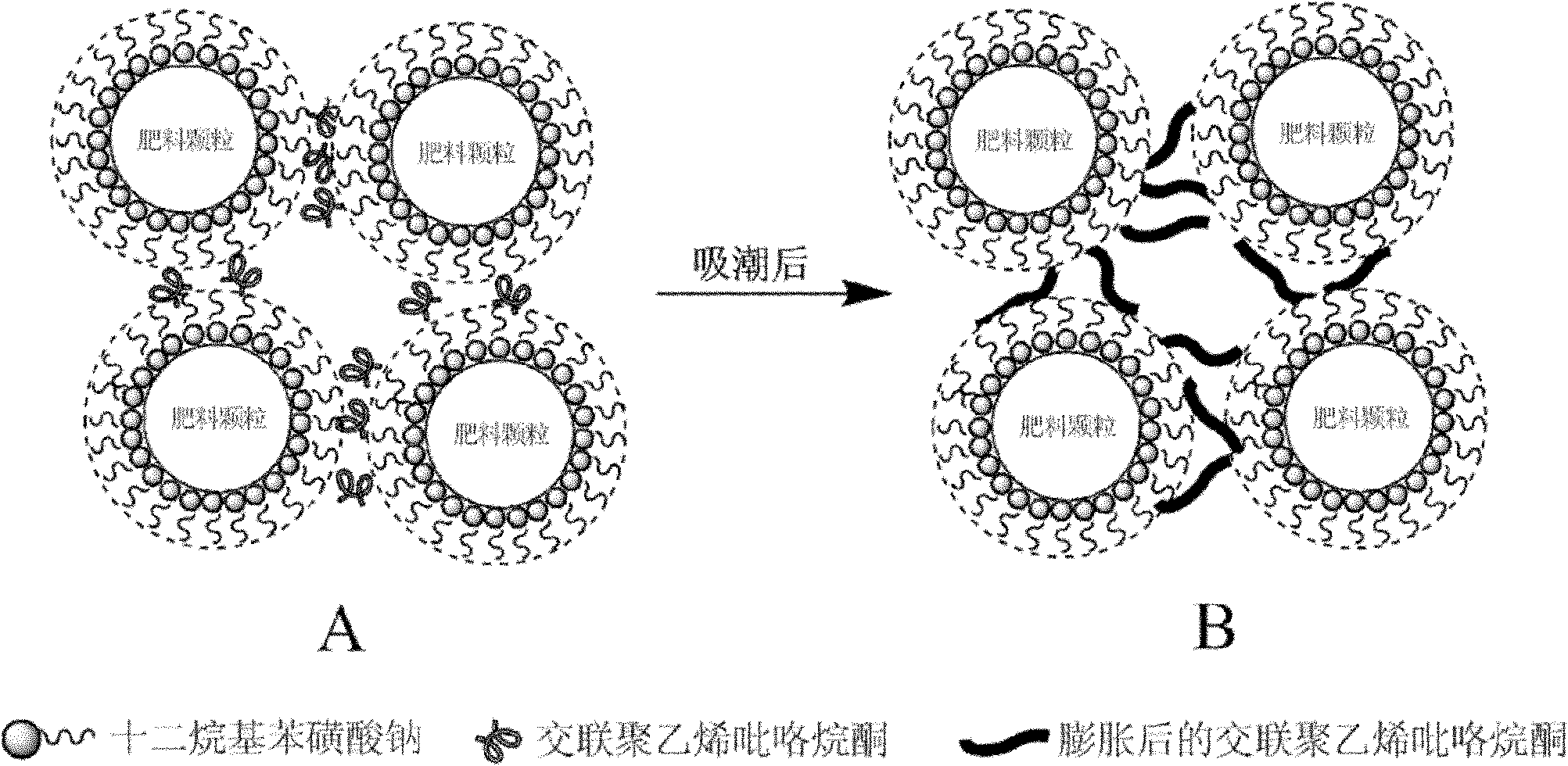

Method used

Image

Examples

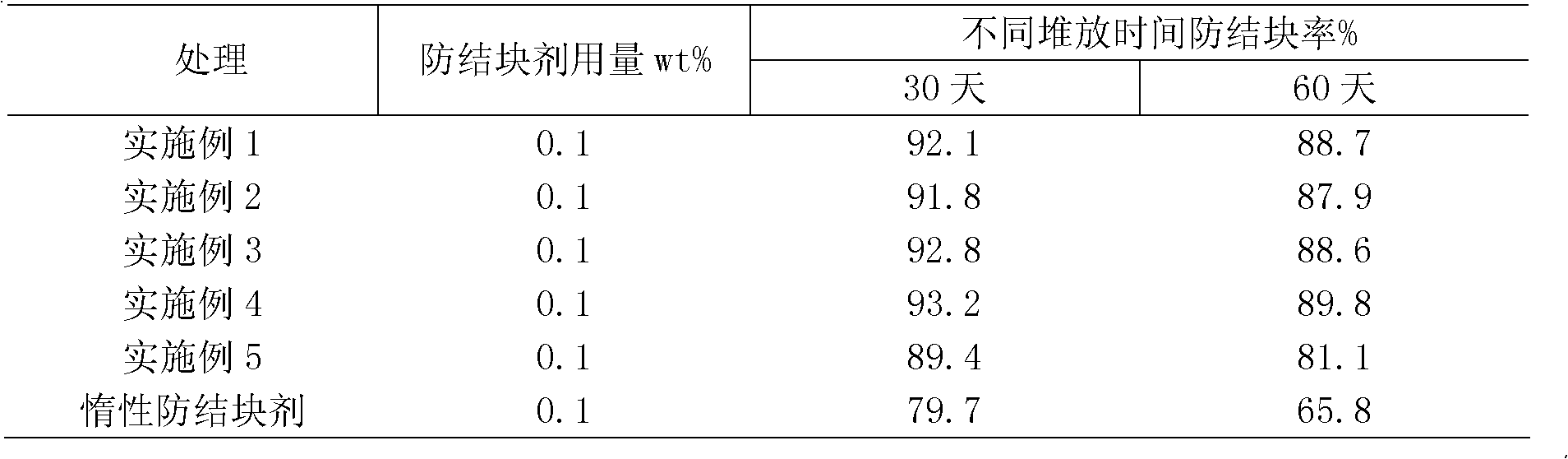

Embodiment 1

[0039] Add 1000kg of water to the reaction kettle, heat to 76°C and add 180kg of sodium dodecylbenzenesulfonate and 20kg of cross-linked polyvinylpyrrolidone under stirring, keep warm at 76°C and stir for 20min, and obtain a solution containing anti-caking agent after filtration.

[0040] Application: Send the solution containing anti-caking agent to the dual-fluid nozzle or nozzle group, atomize it and spray it on the fertilizer particles at 70°C in the coating machine. The coating machine rotates at 50 rpm to prevent caking. The amount of block agent is 0.1%. At the same time, the fertilizer in the coating machine is heated to 80°C-100°C for heating and drying. After stopping spraying, continue to heat and dry for 5 minutes, and the surfactant and polymer in the anti-caking agent solution can be formed. Needle crystals are uniformly dispersed in fertilizer granules. After cooling, discharge and pack.

Embodiment 2

[0042] Add 1000kg of water to the reaction kettle, heat to 73°C and add 170kg of sodium tetradecylbenzenesulfonate and 20kg of cross-linked polyvinylpyrrolidone under stirring, keep warm at 73°C and stir for 22min, and obtain a solution of anti-caking agent after filtration.

[0043]Application: Send the anti-caking agent solution to the two-fluid nozzle and spray it on the fertilizer particles at 75°C in the coating machine, the coating machine rotates at 50 rpm, and the amount of anti-caking agent is 0.1% , At the same time, heat the fertilizer in the coating machine to 80 ℃ ~ 100 ℃ for heating and drying, stop spraying and continue heating and drying for 5 minutes. After cooling, discharge and pack.

Embodiment 3

[0045] Add 1000kg of water to the reaction kettle, heat to 70°C and add 165kg of sodium hexadecylbenzenesulfonate and 25kg of cross-linked polyvinylpyrrolidone under stirring, keep warm at 70°C and stir for 20min, and filter to obtain a solution containing an anti-caking agent.

[0046] Application: Send the anti-caking agent solution to the nozzle group, atomize it and spray it on the fertilizer particles at 65°C in the coating machine; the coating machine rotates at 60 rpm, and the amount of anti-caking agent is 0.1%. At the same time, heat the fertilizer in the coating machine to 80°C to 100°C for heating and drying, stop spraying and continue heating and drying for 5 minutes, and then discharge and pack after cooling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com