Laser for generating high-power axisymmetric polarized light

An axisymmetric polarized light and laser technology, applied in the field of lasers, can solve the problem of axis-symmetrical polarized light that is not conducive to outputting high power and high degree of polarization. Efficient output of radially polarized light polarization degree and other issues, to achieve the effect of easy popularization, low loss and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

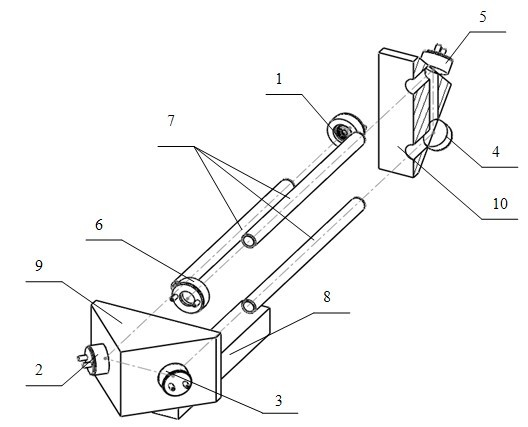

[0044] Such as Figure 16 In the specific structure of the dielectric grating mirror shown, gallium arsenide is used in both the substrate and the grating region. φ 1 27.94 mm, φ 2 22.00 mm, φ 3 is 0.20 mm. The high refractive index material of the multilayer dielectric film is zinc selenide, the low refractive index material is thorium tetrafluoride, and the number of layers of the multilayer dielectric film is 5 layers. The period Λ of the grating is 6 microns, the ridge width b of the grating is 3 microns, and the reflectance curves of two kinds of polarized light are calculated by changing the depth h of the grating, such as Figure 17 shown. When the grating depth h is in the interval A near 1.50 microns (h is greater than 1.40 microns and less than 1.75 microns), the reflectivity of the normal incident P polarization component exceeds 99.0%, while the normal incident S polarization component reflectance is less than 53.54 %. Similarly, when the grating depth h is ...

example 2

[0046] Such as Figure 13 In the inner axicon metal grating mirror structure shown, both the base and the grating area are made of red copper. φ a 24.0 mm, φ b is 2.0 mm and b is 11.0 mm. The period Λ of the grating is 10 microns, the ridge width b of the grating is 5 microns, and the reflectance curves of two kinds of polarized light are calculated by changing the depth h of the grating, such as Figure 18 shown. When the grating depth h is in the interval C near 5.20 microns (h is greater than 5.1 microns and less than 5.3 microns), the reflectivity of the metal grating to the P polarization component incident at 45° exceeds 97.4%, so the inner axicon metal grating mirror is The reflectivity of the normal incident P polarization component exceeds 94.9%, while the reflectivity of the metal grating to the incident S polarization component at 45° is less than 65.0%, so the reflectivity of the inner axicon metal grating mirror to the normal incident S polarization component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com