Method for producing flammulina velutiper foot mushroom sauce

A production method and technology for mushroom sauce, applied in application, food preparation, food science and other directions, can solve problems such as poor shape and loss, and achieve the effects of fine taste, prevention of cell degradation, and rich natural flavor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A kind of production method of Flammulina velutipes foot mushroom sauce, it comprises the steps:

[0032] A, the foot mushroom of Flammulina velutipes is dried to obtain dried foot mushroom;

[0033] B. Soak the dried foot mushrooms in step A after adding water;

[0034] C, add red pepper to the foot mushroom soaked, and obtain the foot mushroom premix after crushing;

[0035] D. Stir-fry the premixed mushroom with edible oil and cook, then add seasonings and mix evenly to obtain Flammulina velutipes mushroom sauce;

[0036] E. Filling and sterilization.

[0037] Concrete process step and process condition among the present embodiment also have:

[0038] The drying of the foot mushroom in the step A adopts the method of microwave drying, and the drying conditions are: the power of microwave drying is 200-300 watts, and the time is 3-5 minutes.

[0039] In step B, the ratio of mass and volume of mushroom to water is 1:15, the soaking temperature is 25°C, and the time...

Embodiment 2

[0044] The drying of the foot mushroom in step A adopts the method of microwave drying, and the drying conditions are: the power of microwave drying is 250 watts, and the drying time is 4 minutes.

[0045] In order to ensure the mouthfeel of the foot mushrooms while retaining the nutrients in the foot mushrooms as much as possible, the preferred technical implementation method is that the mass volume ratio of the foot mushrooms to water in step B is 1:20, and the soaking temperature is 50°C. The time is 20 minutes.

[0046] The mass-to-number ratio of soaked foot mushrooms and red peppers in step C=145:1.2.

[0047] The seasoning in step D is white sugar, chicken essence, salt, starch and soy sauce, according to the mass fraction ratio of the mushroom premix after stir-frying: white sugar: chicken essence: salt: starch: soy sauce = 145:10-18:0.6:5 : 3-8: 10 ratio, mix the stir-fried and matured foot mushroom premix and seasoning evenly to obtain Flammulina velutipes foot mush...

Embodiment 3

[0050] The drying of the foot mushroom in step A adopts the method of microwave drying, and the drying conditions are: the power of microwave drying is 200 watts, and the drying time is 5 minutes.

[0051] In step B, the ratio of mass and volume of mushrooms to water is 1:30, the soaking temperature is 60°C, and the time is 15 minutes.

[0052] The mass-to-number ratio of soaked foot mushrooms and red peppers in step C=160:1.5.

[0053] The seasoning in step D is white sugar, chicken essence, salt, starch and soy sauce, according to the mass fraction ratio of the stir-fried mushroom premix: white sugar: chicken essence: salt: starch: soy sauce = 161.5: 18: 0.8: 6: 8 : The ratio of 12, mix the stir-fried and matured foot mushroom premix and seasoning evenly to obtain Flammulina velutipes foot mushroom sauce.

[0054] Sterilization adopts high temperature sterilization, and the conditions are as mentioned above.

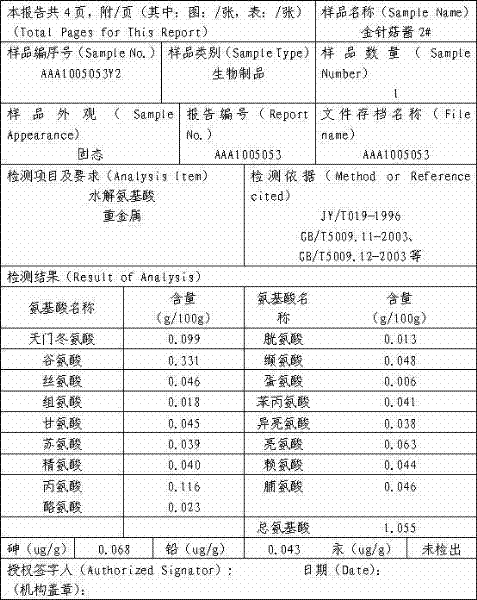

[0055] The assay results of the amino acids in the foregoing ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com