Method for preparing potassium sulfate with co-products of aluminum sulfate and ferric sulfate by using alum sludge hydrolysis filtrate

A technology of potassium sulfate and aluminum sulfate, applied in the direction of alkali metal sulfite/sulfite, aluminum sulfate, iron sulfate, etc., can solve the problems of less product types, secondary pollution, and low grades

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

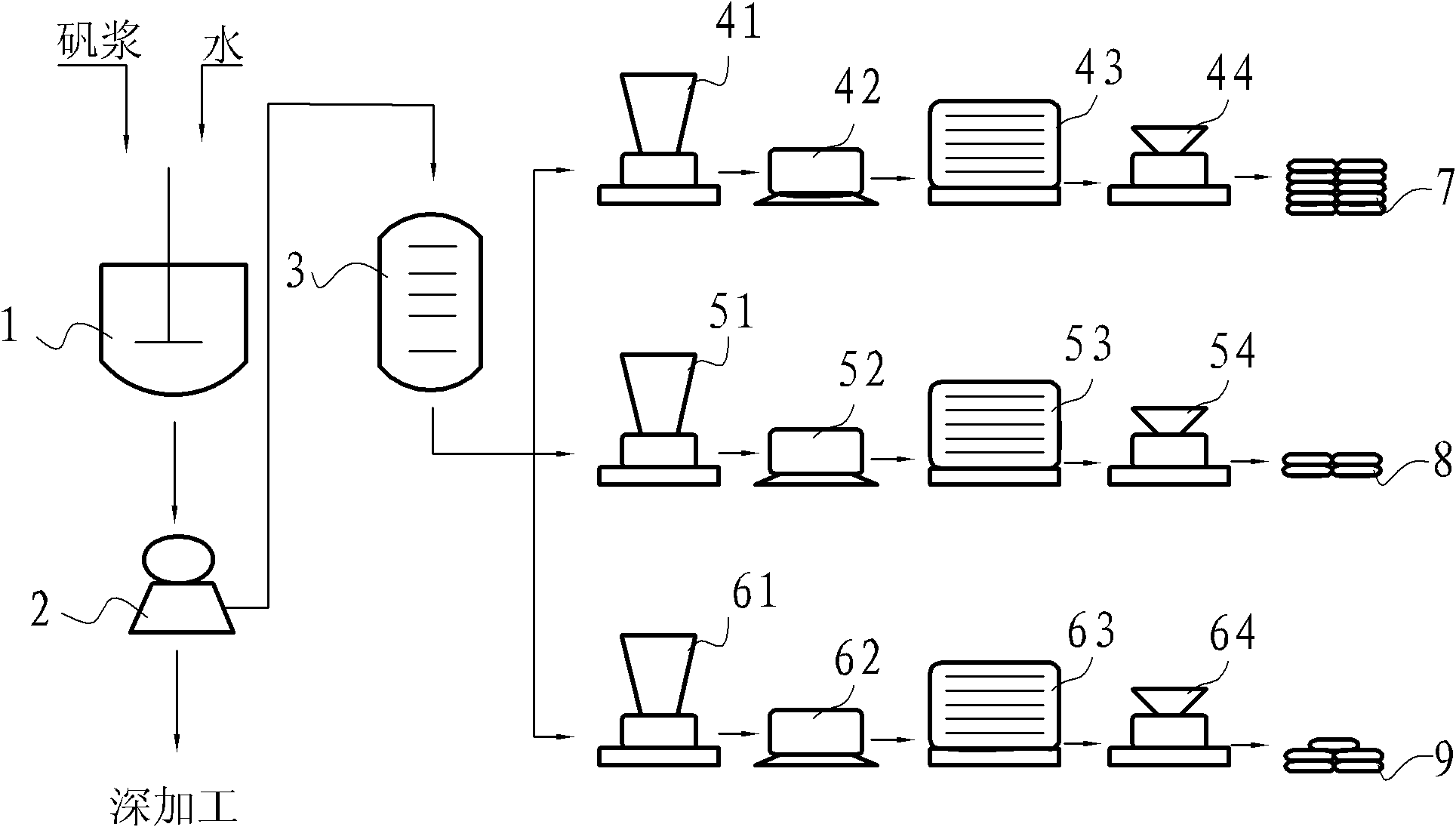

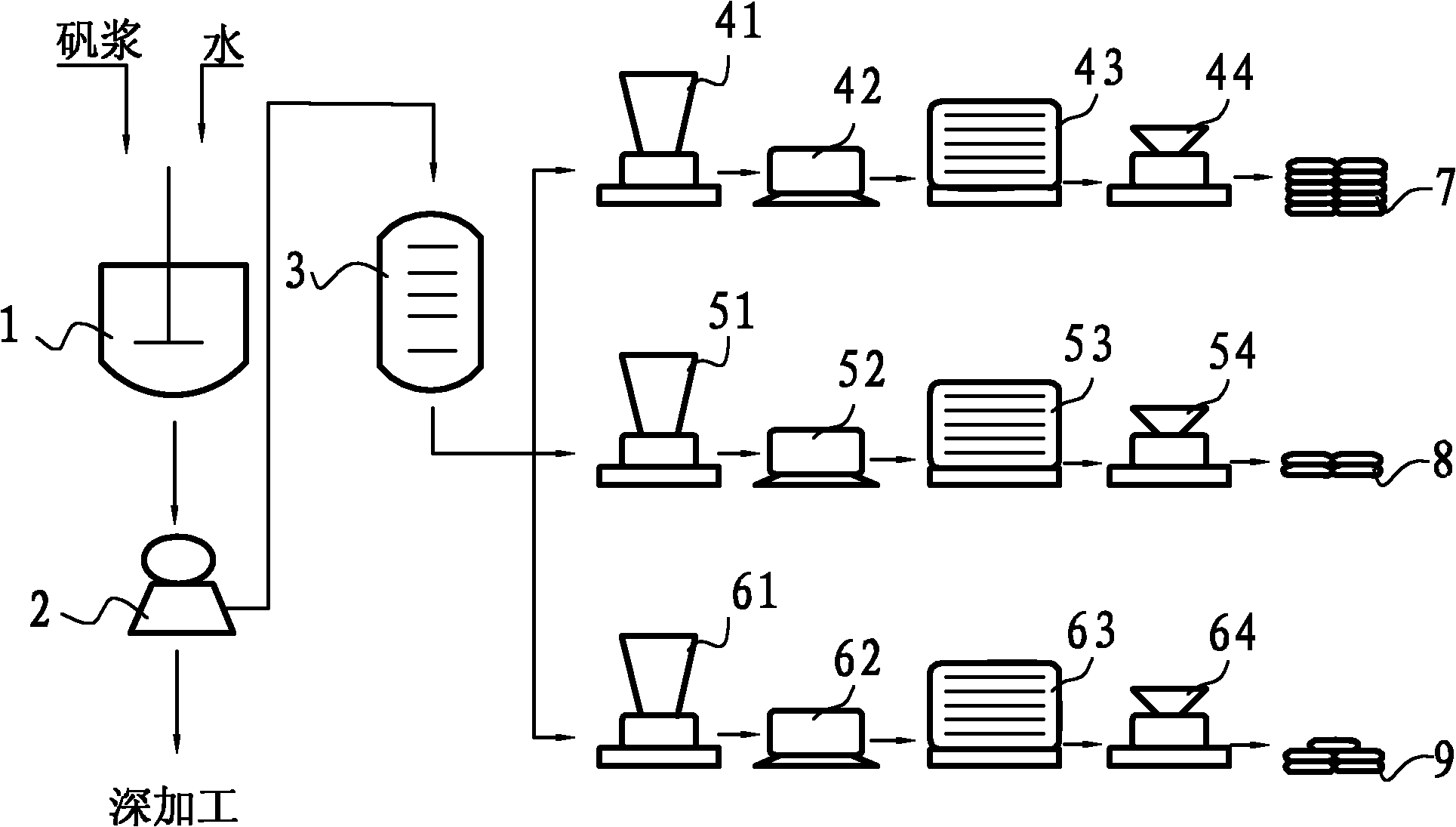

[0025] A method for preparing potassium sulfate co-production of aluminum sulfate and ferric sulfate with alum mud hydrolysis filtrate, comprising the following preparation steps:

[0026] Step A, put 1000Kg of alum slurry into a corrosion-resistant reactor 1, add 1 to 3 times of water to fully stir, and hydrolyze to obtain a mixture of potassium sulfate, aluminum sulfate and iron sulfate; wherein the alum slurry is 155.2Kg pure Calculation of sulfur trioxide, 444Kg potassium hydroxide, 430.3Kg aluminum hydroxide and 229Kg iron hydroxide;

[0027] Step B, filtering the mixed substance obtained in step A with a filter 2;

[0028] Step C, sending the filter cake obtained by filtering in step B for further processing;

[0029] Step D, the filtrate obtained by filtering in step B is sent to the corrosion-resistant vacuum distiller 3 for vacuum distillation. When the solution reaches a saturated solution, according to the difference in the freezing point of the three substances, u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com