Integrated reaction-separation method and device for preparing mannitol

An integrated reaction, mannitol technology, applied in ion exchange treatment device, ion exchange, ion exchange regeneration and other directions, can solve the problems of heavy pollution, lack of market competitiveness of kelp extraction method, high energy consumption, etc., to achieve simple process, extraction High purity and efficiency, resulting in improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

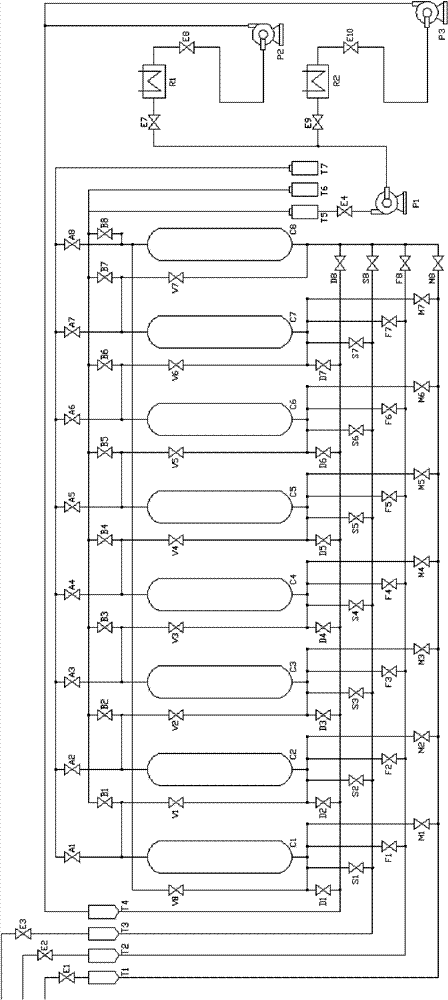

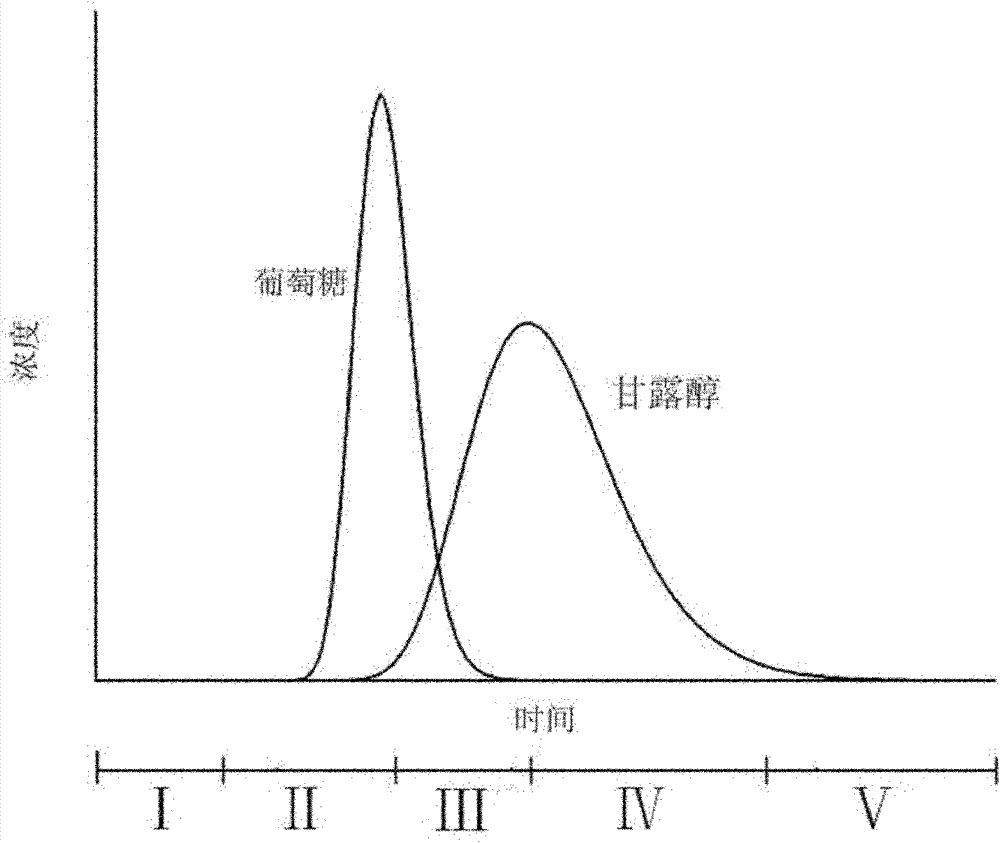

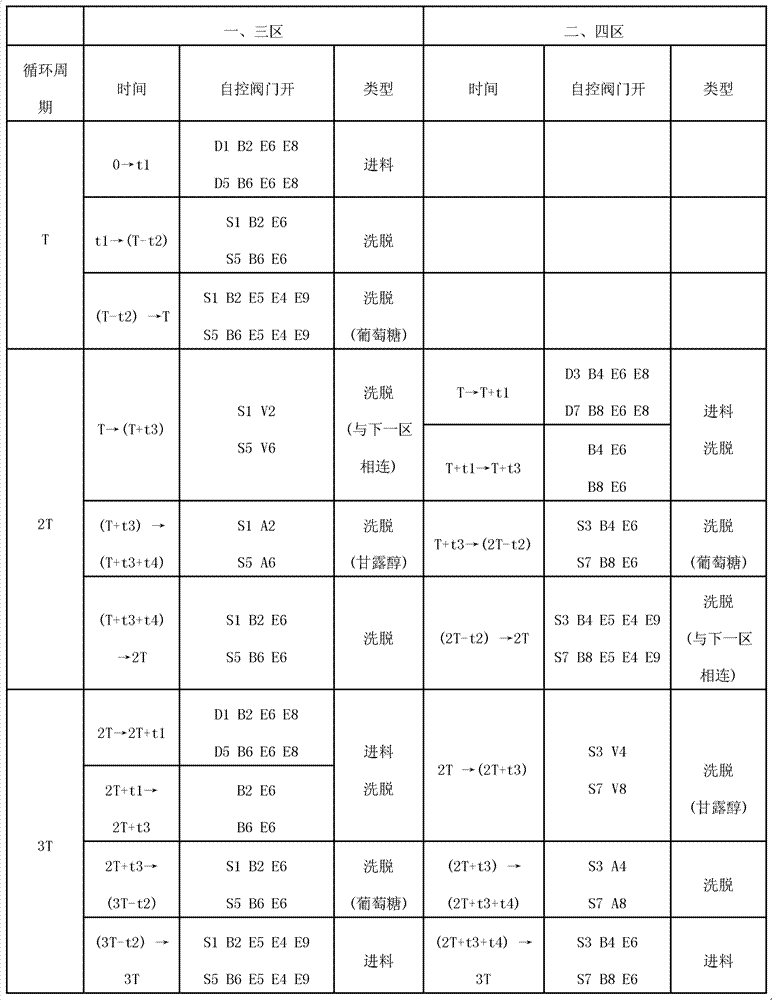

Embodiment 1

[0035] Turn on the constant current power supply to supply power to the mannitol electrochemical reactor R1 respectively, prepare an anode solution with a sulfuric acid concentration of 1 mol / L; prepare a cathode solution with a sodium sulfate concentration of 0.45 mol / L and a glucose concentration of 0.6 mol / L. Turn on the constant current power supply with a current density of 5A / dm 3 , the temperature is 30-60°C. After 2 hours of electrochemical reaction, a mixed solution of glucose and mannitol was obtained. At this point, it begins to enter the separation cycle process of 8 columns and 4 zones. During the separation process, 8 columns form 4 zones, and each zone is a small simulated moving bed process formed by two chromatographic separation columns connected in series. Separated products are cut out at different stages, such as the automatic control valve connected to the mannitol extraction tank during the extraction stage of mannitol in the separation process, the aut...

Embodiment 2

[0039] Turn on the constant current power supply to supply power to the mannitol electrochemical reactor R1 respectively, prepare an anode solution with a sulfuric acid concentration of 1 mol / L; prepare a cathode solution with a sodium sulfate concentration of 0.45 mol / L and a glucose concentration of 0.6 mol / L. Turn on the constant current power supply with a current density of 5A / dm 3 , the temperature is 30-60°C. After 2 hours of electrochemical reaction, a mixed solution of glucose and mannitol was obtained. At this point, it begins to enter the separation cycle process of 8 columns and 4 zones. During the separation process, 8 columns form 4 zones, and each zone is a small simulated moving bed process formed by two chromatographic separation columns connected in series. Separated products are cut out at different stages, such as the automatic control valve connected to the mannitol extraction tank during the extraction stage of mannitol in the separation process, the aut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com