Method for texturing surface of monocrystalline silicon solar battery

A solar cell and surface texture technology, which is applied to circuits, electrical components, sustainable manufacturing/processing, etc., can solve the problems of large thickness of monocrystalline silicon, increased production cost, and difficulty in control, and achieve low cost and reduced corrosion Speed, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

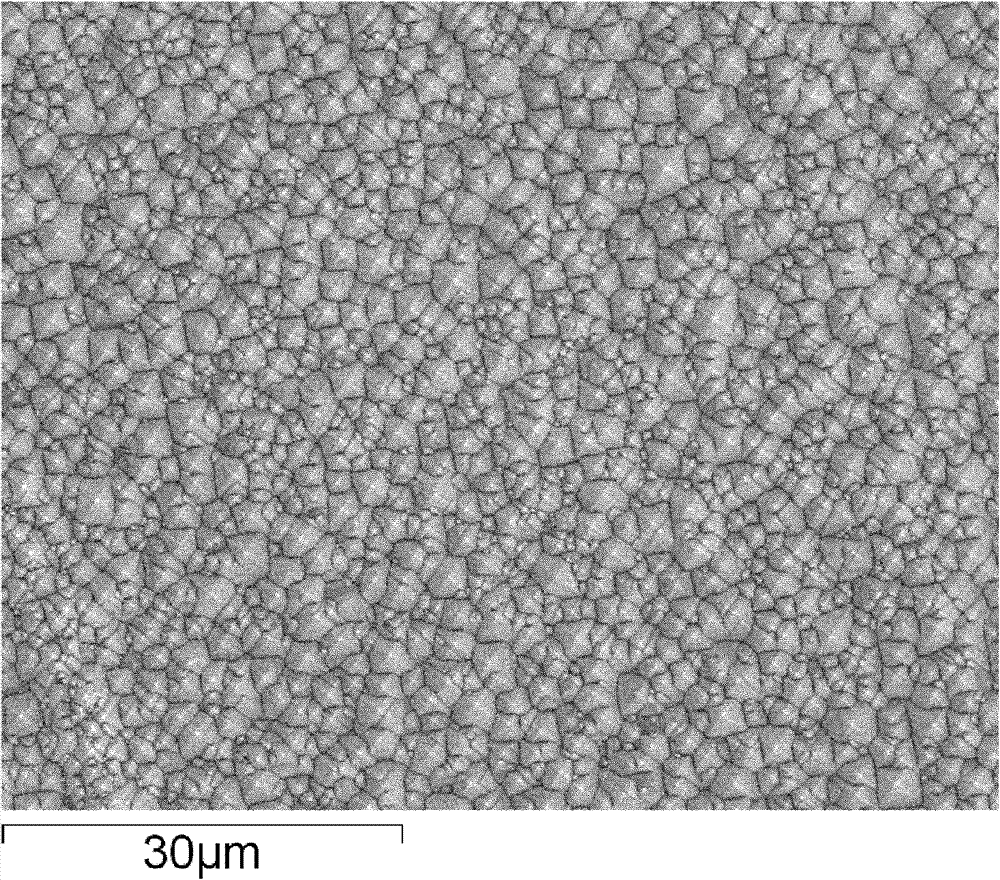

[0022] Example 1: Prepare a mixed solution of 0.01% detergent spirit and 0.1% sodium hydroxide in an ultrasonic tank, heat the mixed solution to 90° C., and ultrasonically clean the single crystal silicon wafer for 2.5 minutes. After rinsing, spray G solution evenly on the surface of the monocrystalline silicon wafer, and prepare an alkaline etching solution in a constant temperature bath: 1.5% sodium hydroxide by mass, 1.5% isopropanol by volume, and 0.5% by volume % concentration is 1 x 10 -3 mol / L alkylsulfonate aqueous solution, the reaction temperature is 75°C, and the corrosion time is 18min. The monocrystalline silicon that can obtain like this has pyramid suede, has formed uniform pyramid suede on the surface of this single crystal silicon under the scanning electron microscope, and the side length of pyramid is about 2 μ m, and corrosion thickness is 12 μ m (such as figure 1 shown).

Embodiment 2

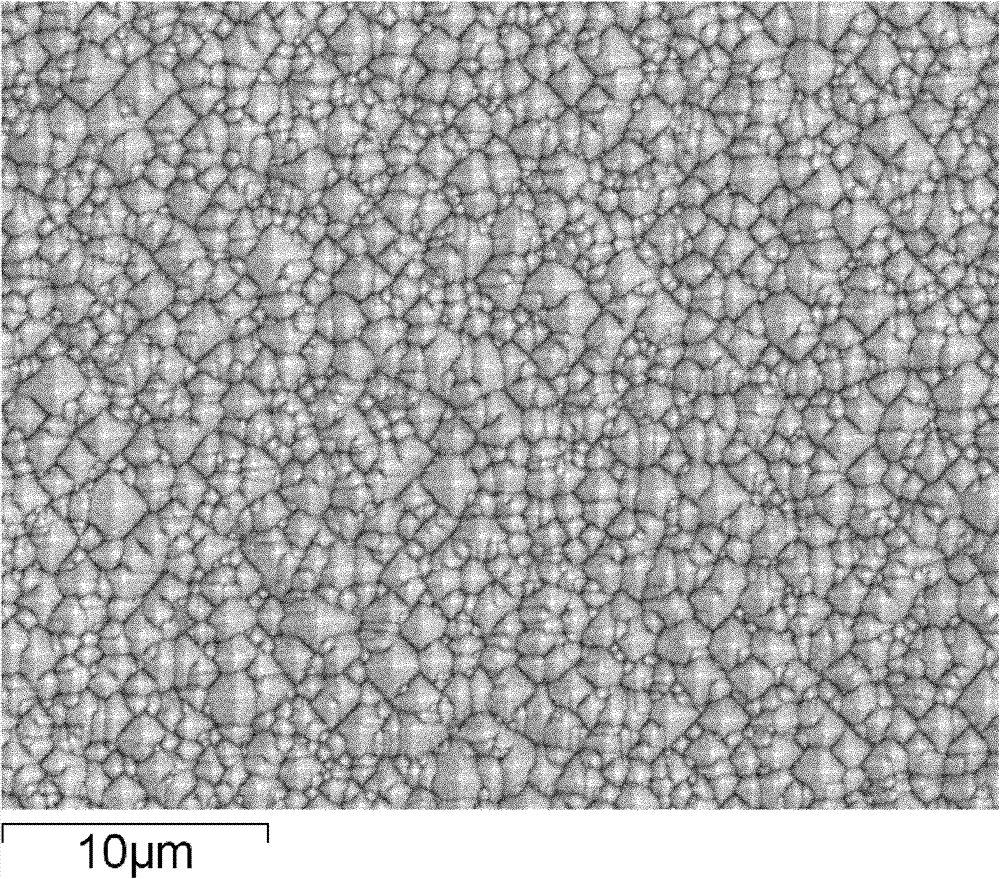

[0023] Example 2: Prepare a solution of 0.015% detergent spirit and 0.15% sodium hydroxide solution in an ultrasonic tank, and heat the mixed solution to 85° C., and ultrasonically clean the single crystal silicon wafer for 4 minutes. After rinsing, spray G solution evenly on the surface of the single crystal silicon wafer, and prepare an alkaline etching solution in a constant temperature tank: 1% sodium hydroxide by mass, 1% isopropanol by volume, and 0.3% by volume The concentration is 1×10 -3 mol / L alkylsulfonate aqueous solution, the reaction temperature is 80°C, and the corrosion time is 15min. The monocrystalline silicon that can obtain like this has pyramid suede, has formed uniform pyramid suede on the surface of monocrystalline silicon under the scanning electron microscope, and the side length of pyramid is about 1.5 μ m, and corrosion thickness is 10 μ m (such as figure 2 shown).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com