Nitride ceramic fiber reinforced inorganic non-metal composite material and preparation method thereof

A technology of nitride ceramics and inorganic non-metals, which is applied in the field of ceramic matrix composite materials and its preparation, can solve the problems of high dielectric constant and dielectric loss, unsatisfactory oxidation resistance and strength, etc., and achieve low dielectric constant, Effects of low dielectric loss and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

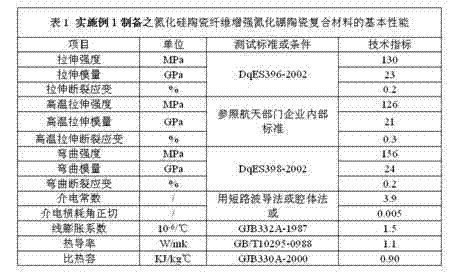

Embodiment 1

[0026] In the nitride ceramic fiber-reinforced inorganic non-metallic composite material of this embodiment, the matrix is boron nitride ceramics, and the reinforcing phase is silicon nitride ceramic fibers.

[0027] Preparation:

[0028] (1) Preparation of nitride ceramic fiber braid

[0029] Using a 2.5D weaving structure, weaving silicon nitride ceramic fibers into a three-dimensional fabric on the mold, the fiber volume fraction is 40%;

[0030] (2.) Nitride ceramic fiber braid pretreatment

[0031] Place the nitride ceramic fiber braid prepared in step (1) in a high-temperature furnace, raise the temperature to 500°C in a vacuum environment, keep it for 60 minutes, cool down to room temperature, and take it out for use;

[0032] (3) Matrix material precursor impregnation, thermal crosslinking and curing, cracking

[0033] Place the braided nitride ceramic fiber pretreated in step (2) in a vacuum impregnation tank. After vacuuming, the braided fabric is immersed in th...

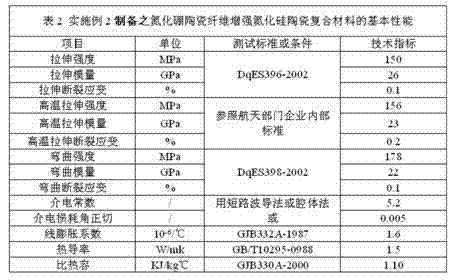

Embodiment 2

[0040] In the nitride ceramic fiber-reinforced inorganic non-metallic composite material of this embodiment, the matrix is silicon nitride ceramics, and the reinforcing phase is boron nitride ceramic fibers.

[0041] Preparation:

[0042] (1) Same as step (1) of Example 1, except that the ceramic fibers are boron nitride ceramic fibers;

[0043] (2) Place the boron nitride ceramic fiber braid prepared in step (1) in a high-temperature furnace, raise the temperature to 600°C in a vacuum environment, keep it for 60 minutes, cool down to room temperature, and take it out for use;

[0044] (3) Matrix material precursor impregnation, thermal crosslinking and curing, cracking

[0045] Place the nitride ceramic fiber braid treated in step (2) in a vacuum impregnation tank, and after vacuuming to 60Pa, immerse the braid in perhydropolysilazane for 120 minutes; then pressurize in a closed container to 6MPa, heat to 120°C, keep warm for 40h to cross-link and solidify the material in...

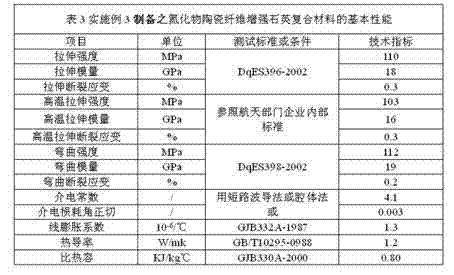

Embodiment 3

[0052] The nitride ceramic fiber-reinforced inorganic non-metallic composite material in this embodiment has a matrix of quartz ceramics and a reinforcing phase of ceramic fibers containing silicon-nitrogen-boron elements (ie, silicon-nitrogen-boron ceramic fibers).

[0053] Preparation:

[0054] (1) Same as step 1 in Example 1; only the ceramic fibers are silicon nitride boron ceramic fibers

[0055] (2) Place the boron nitride ceramic fiber braid prepared in step (1) in a high-temperature furnace, raise the temperature to 550°C in a vacuum environment, keep it for 120 minutes, cool down to room temperature, and take it out for use;

[0056] (3) Matrix material precursor impregnation, thermal crosslinking and curing, cracking

[0057]Place the silicon nitride boron ceramic fiber braid treated in step (2) in a vacuum impregnation tank, suck the matrix material precursor silica sol into the braid after vacuuming, and then heat it to 80°C in an open container, Keep warm for 60...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com