Boiling assistant for preparing high polymerised pulp

A cooking aid and high degree of polymerization technology, which is used in cellulose raw material pulping, textiles and papermaking, papermaking, etc., can solve the problem that cooking aids cannot meet ultra-high whiteness, and achieves promotion of swelling and fracture. Long, improve the effect of full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

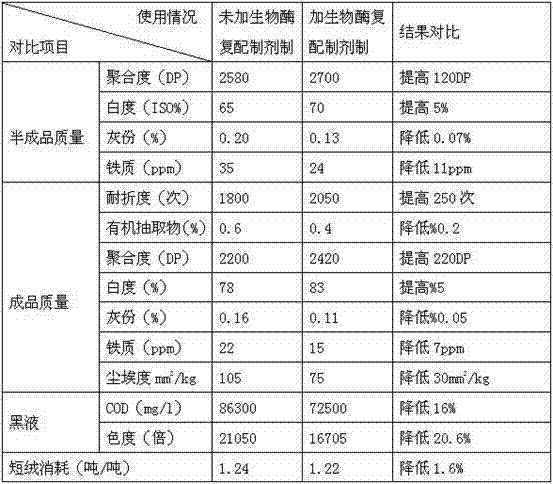

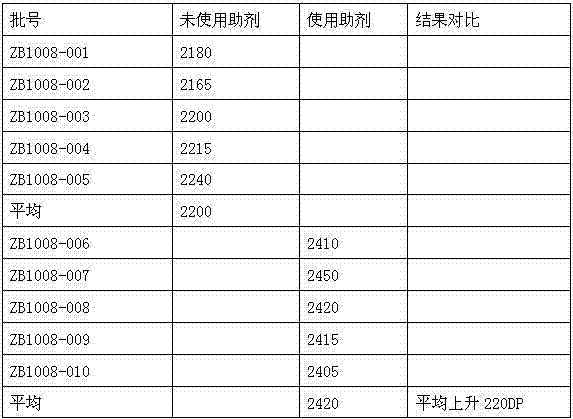

Examples

Embodiment 1

[0036] A. Cotton opening: After the cotton linters are unpacked, they are sent to the cotton opener by the conveyor belt, and after being shredded by large and small licker-in rollers, they are sent to the cyclone separator by wind;

[0037] B. Dry impurity removal: The cyclone separator is connected in series with the fiber impurity removal and sorting machine. When the air is sent, under the action of gravity, the cotton seed hulls and other impurities are separated from the cotton linter fibers;

[0038] C. Configure biological enzyme compound preparation: sodium sulfite, α-methylanthraquinone (α-MAQ), lipase, hemicellulase, lignin degrading enzyme, DTPA (diethylenetriaminepentaacetic acid), dodecane Sodium phenyl sulfonate is calculated by weight percentage: sodium sulfite 30%; α-methylanthraquinone 10%; lipase 5%; hemicellulase 10%; lignin degrading enzyme 10%; Sodium benzenesulfonate 25% is evenly mixed and prepared into a compound preparation for use;

[0039] D. Confi...

Embodiment 2

[0044] A. Cotton opening: After the cotton linters are unpacked, they are sent to the cotton opener by the conveyor belt, and after being shredded by large and small licker-in rollers, they are sent to the cyclone separator by wind;

[0045] B. Dry impurity removal: The cyclone separator is connected in series with the fiber impurity removal and sorting machine. When the air is sent, under the action of gravity, the cotton seed hulls and other impurities are separated from the cotton linter fibers;

[0046] C. Configure biological enzyme compound preparation: sodium sulfite, α-methylanthraquinone (α-MAQ), lipase, hemicellulase, lignin degrading enzyme, DTPA (diethylenetriaminepentaacetic acid), dodecane Sodium phenyl sulfonate is calculated by weight percentage: sodium sulfite 38%; α-methylanthraquinone 5%; lipase 15%; hemicellulase 1%; lignin degrading enzyme 1%; Sodium benzenesulfonate 30% is uniformly mixed and prepared into a compound preparation for use;

[0047] D. Conf...

Embodiment 3

[0052] A. Cotton opening: After the cotton linters are unpacked, they are sent to the cotton opener by the conveyor belt, and after being shredded by large and small licker-in rollers, they are sent to the cyclone separator by wind;

[0053] B. Dry impurity removal: The cyclone separator is connected in series with the fiber impurity removal and sorting machine. When the air is sent, under the action of gravity, the cotton seed hulls and other impurities are separated from the cotton linter fibers;

[0054] C. Configure biological enzyme compound preparation: sodium sulfite, α-methylanthraquinone (α-MAQ), lipase, hemicellulase, lignin degrading enzyme, DTPA (diethylenetriaminepentaacetic acid), dodecane Sodium phenyl sulfonate is calculated by weight percentage: sodium sulfite 50%; α-methylanthraquinone 5%; lipase 5%; hemicellulase 5%; lignin degrading enzyme 5%; Sodium benzenesulfonate 20% is evenly mixed and prepared into a compound preparation for use;

[0055] D. Configur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com