Detection method for in-situ measuring content of phenyllactic acid in fermentation samples

A medium phenyllactic acid and detection method technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of low sensitivity, small capillary diameter, inconvenient on-site detection, etc., and achieve the effect of high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

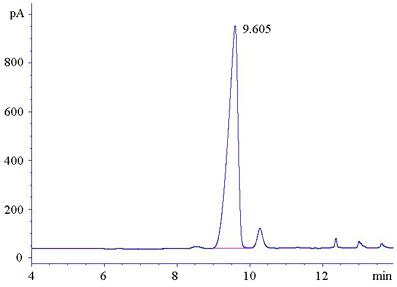

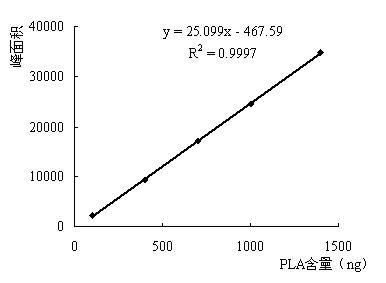

[0022] Embodiment 1 phenyllactic acid standard curve

[0023] A standard solution of phenyllactic acid with a concentration of 2 mg / mL was prepared with phenyllactic acid produced by Alfa Aesar. Take 2mL of the standard solution and heat it to remove water, add 0.3mL of 3.0mol / L concentrated hydrochloric acid-n-butanol mixed solution, shake it and heat it to 70°C for 15 min, N 2 Blow dry the remaining solution. Then add 0.3 mL of trifluoroacetic anhydride-ethyl acetate mixed solution with a volume ratio of 0.3:1, shake it and heat it to 80°C for 15 min in an airtight manner. 2 Blow dry the remaining solution. Add 1 mL of ethyl acetate, shake and centrifuge for 5-7 minutes, take the supernatant and dilute it with ethyl acetate to a concentration of 100, 400, 700, 1000, 1400 μg / mL (based on phenyllactic acid), and take 1 μl (that is, phenyllactic acid Contents were 100, 400, 700, 1000, 1400ng) sample injection, the gas chromatographic results of the first standard (that is, c...

Embodiment 2

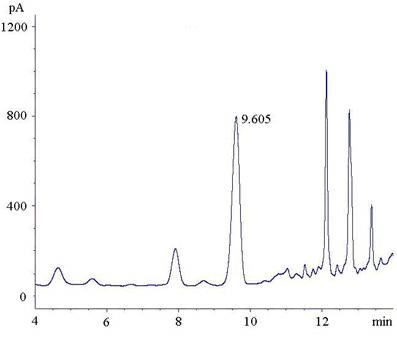

[0028] Example 2 Take the on-site detection of the solid-state fermentation sample a of Mugoniella as an example.

[0029] Sample pretreatment: take 2g of pulverized Mugnittum solid-state fermentation sample, add 2mL of deionized water, shake it upside down several times to fully mix with water, heat and evaporate to dryness, add 3mL of deionized water for shaking (for Dissolve phenyllactic acid) and then centrifuge, take the supernatant and heat to remove water, add 0.3mL of 3.0mol / L concentrated hydrochloric acid-n-butanol mixed solution, vibrate, seal and heat to 70°C for 15 min, N 2 Blow dry the remaining solution. Then add 0.3 mL of trifluoroacetic anhydride-ethyl acetate mixed solution with a volume ratio of 0.3:1, shake it and heat it to 80°C for 15 min in an airtight manner. 2 Blow dry the remaining solution. Add 1 mL of ethyl acetate, shake and centrifuge for 6 min, take the clear and transparent supernatant for gas chromatography analysis, and the injection volume ...

Embodiment 3

[0033] Example 3 Take the on-site detection of Lactobacillus plantarum liquid fermentation sample b as an example.

[0034] Sample pretreatment: Take 2 mL of liquid fermentation sample, heat and evaporate to dryness, add deionized water to shake and dissolve, then centrifuge, take the supernatant and heat to remove water, add 0.3 mL of 3.0 mol / L concentrated hydrochloric acid-n-butanol mixed solution, shake and heat to 70°C for 15 minutes, N 2 Blow dry the remaining solution. Then add 0.3 mL of trifluoroacetic anhydride-ethyl acetate at a volume ratio of 0.3:1, shake and heat in a sealed container to 80°C for 15 min, N 2 Blow dry the remaining solution. Add 1mL of ethyl acetate, shake and centrifuge for 6min, take the clear and transparent supernatant for gas chromatography analysis, the injection volume is 1μl.

[0035] Chromatographic conditions: Chromatographic column DB-1, quartz capillary column with an inner diameter of 15m×0.53mm and a film thickness of 3.0μm, coated w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com