Solid-liquid treatment method of waste smoke agent containing hexachloroethane

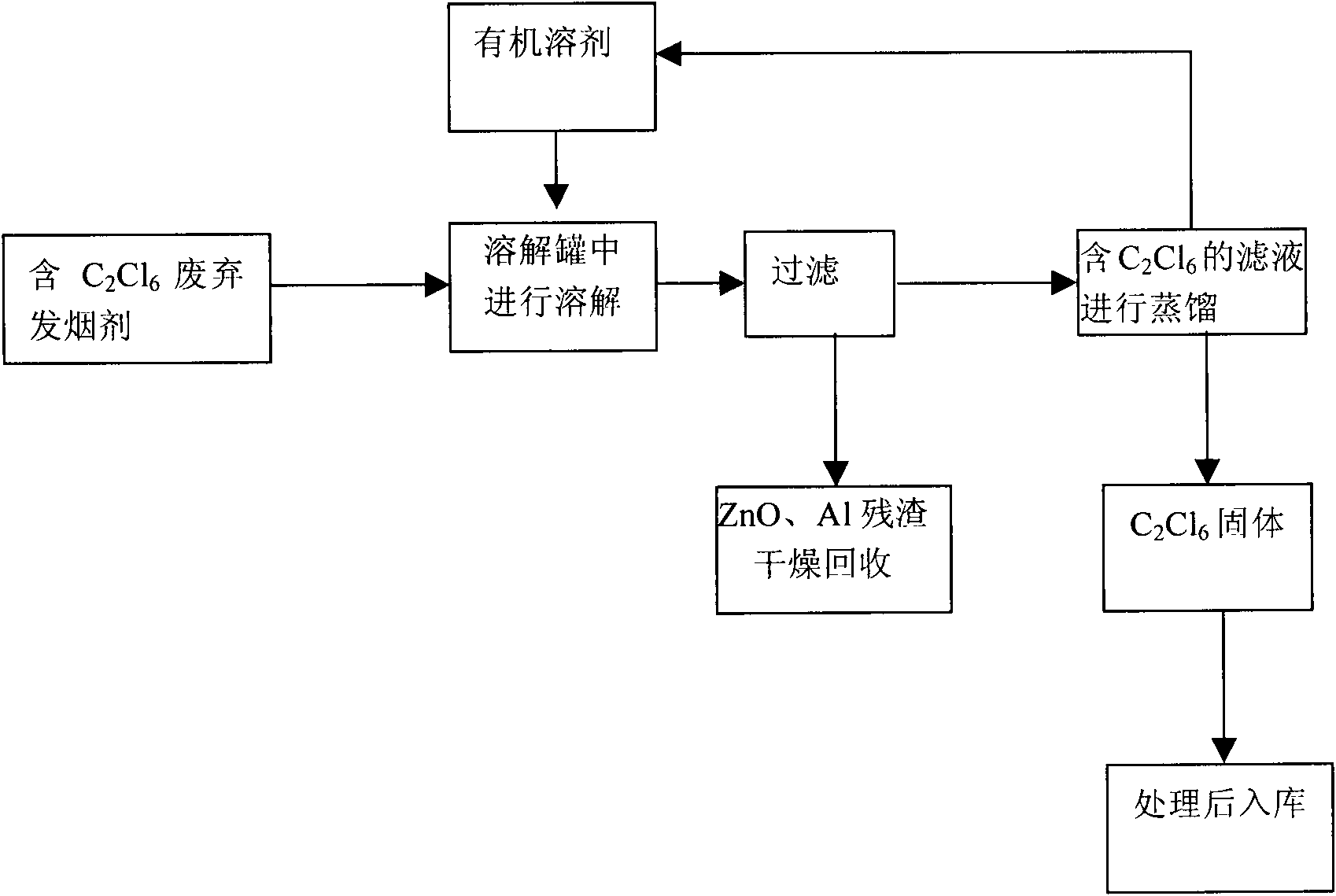

A technology containing hexachloroethane and hexachloroethane, applied in chemical instruments and methods, preparation of halogenated hydrocarbons, organic chemistry, etc., can solve the problem of easy clogging of dust filters and flues, affecting the use effect and use of incineration and destruction systems Life expectancy, environmental pollution and other issues, to achieve the effect of easy control of the operation process, sustainable development, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

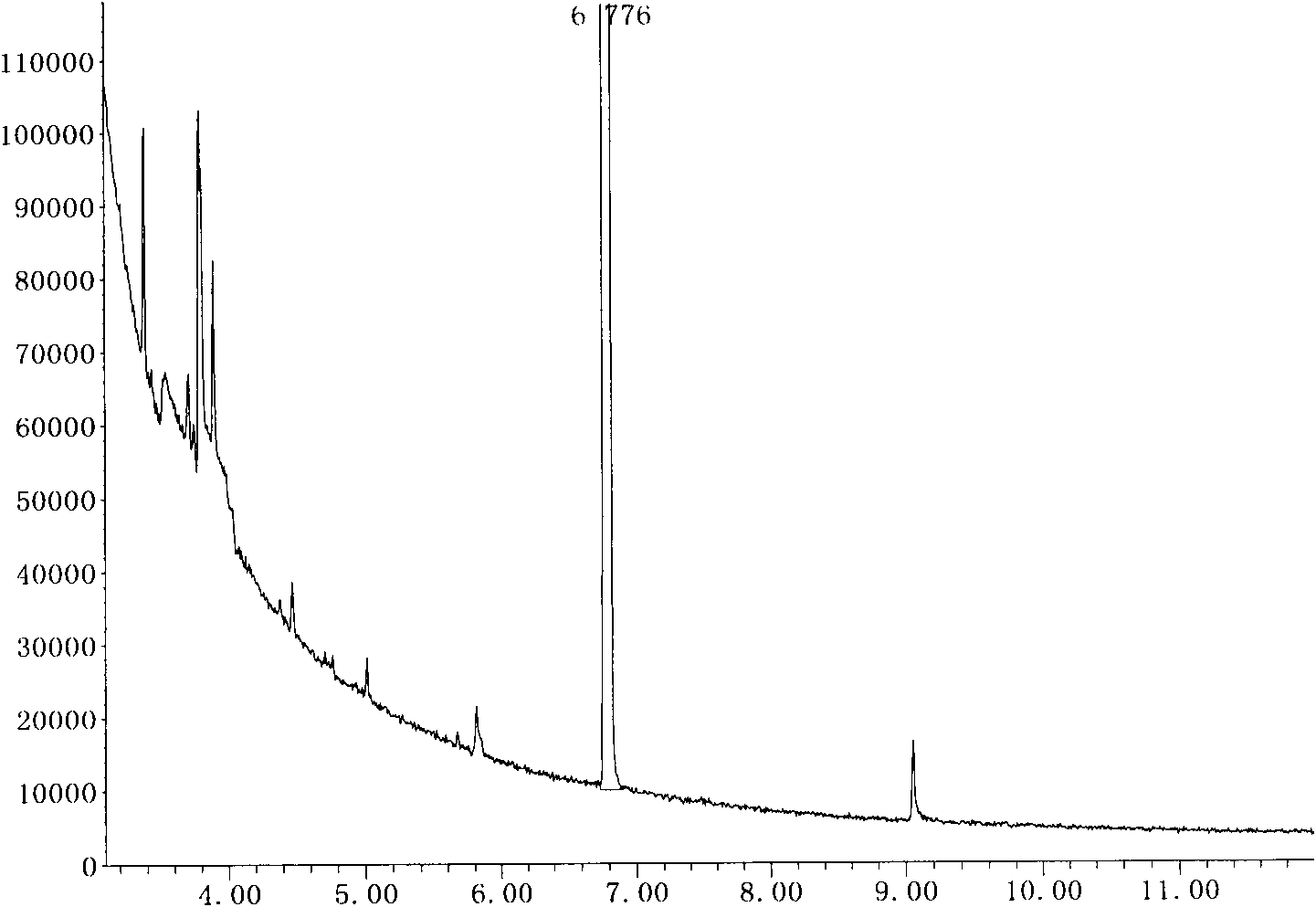

[0021] Remove the fuze from the out-of-store smoke bombs or cans containing the waste smoke agent containing hexachloroethane, and try to scrape off the black powder next to the fuze; Try to prevent iron filings and paint skins from falling into the fuming agent, and crush the poured fuming agent into a powder of more than 40 meshes; pour 100kg of the crushed fuming agent into the dissolving tank, and press solid-liquid Add 1m of analytically pure acetone with a purity of more than 99% at a ratio of 1:20 3 ; The fuming agent after adding acetone is stirred and slurried at normal temperature, the stirring speed is 450r / min, and the stirring time is 2h; The pore size is 260 mesh to 300 mesh, and the filtrate containing hexachloroethane is obtained, and the residue containing ZnO and Al is obtained; the filtrate containing hexachloroethane is distilled under reduced pressure in an evaporator, and the heating temperature is 40°C , the pressure is 150mmHg, the evaporated acetone i...

Embodiment 2

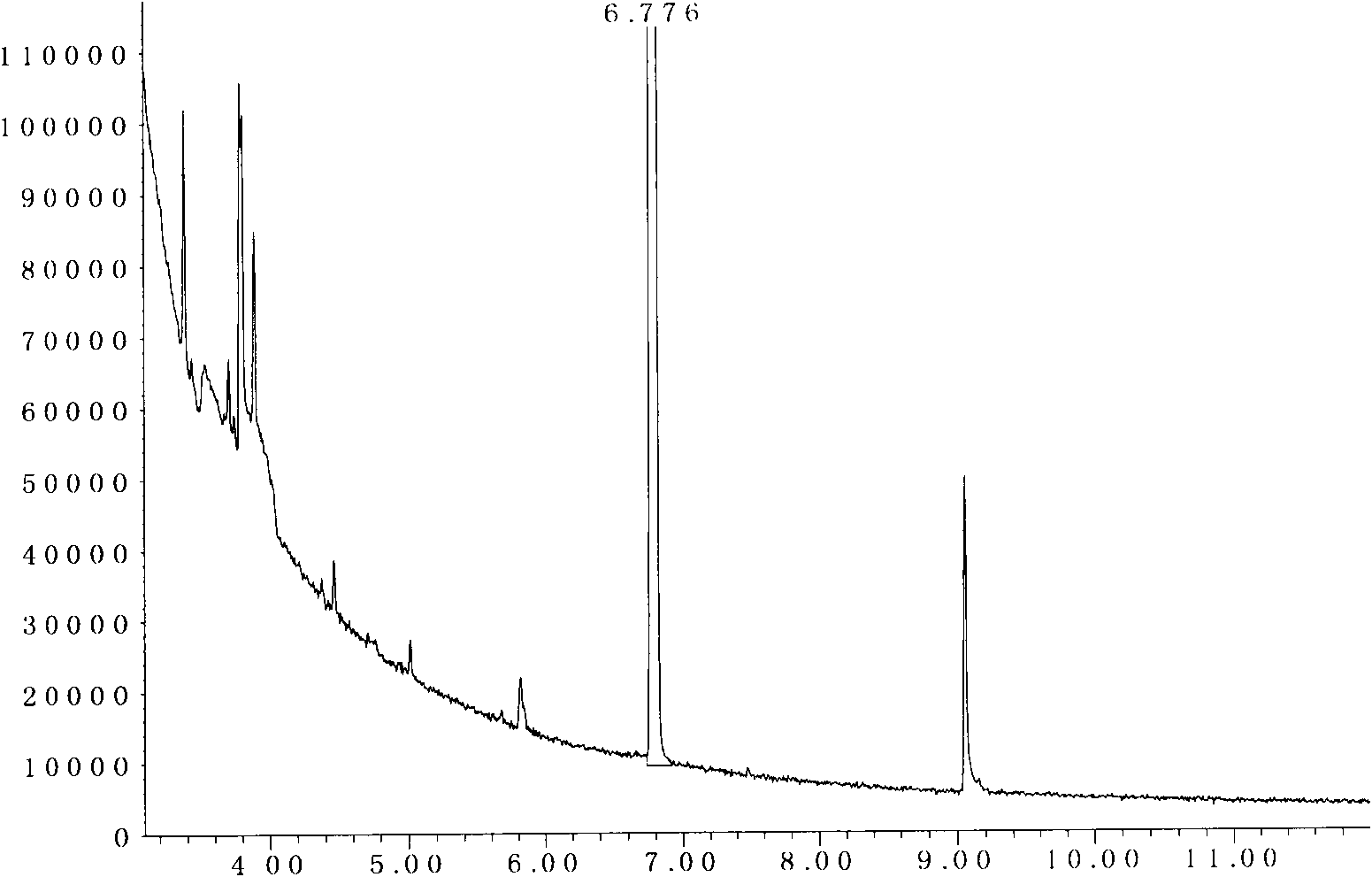

[0024] In this example, the stirring rate is 300r / min, the solid-to-liquid ratio is 1:20, and the other conditions and steps are the same as those in Example 1.

Embodiment 3

[0026] In this example, the stirring rate is 300r / min, the solid-liquid ratio is 1:30, and the other conditions and steps are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com