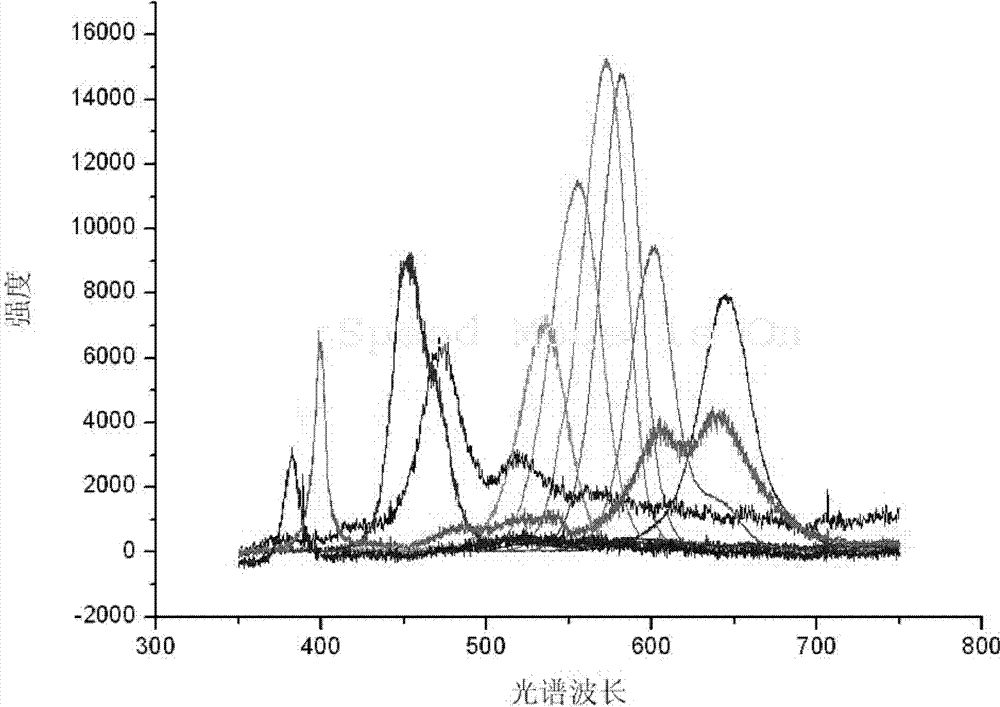

Method and device for preparing zinc cadmium sulfide selenide nanowires with fluorescence changing from ultraviolet to red

A technology of cadmium sulfur selenide and zinc nanowires, which is applied in chemical instruments and methods, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of limited application, fluorescence cannot be continuously and monotonously changed, and achieve constant vacuum change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

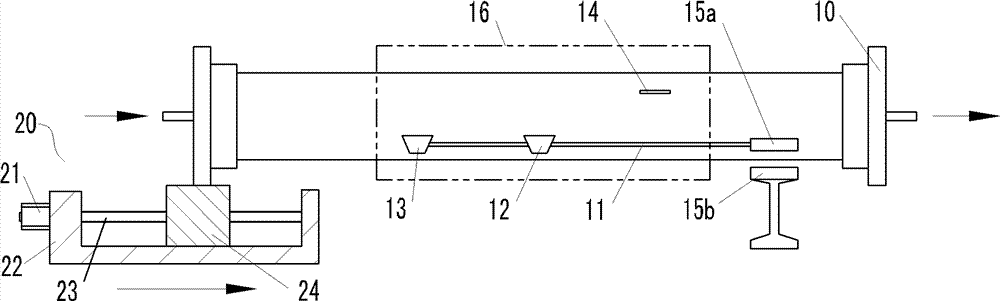

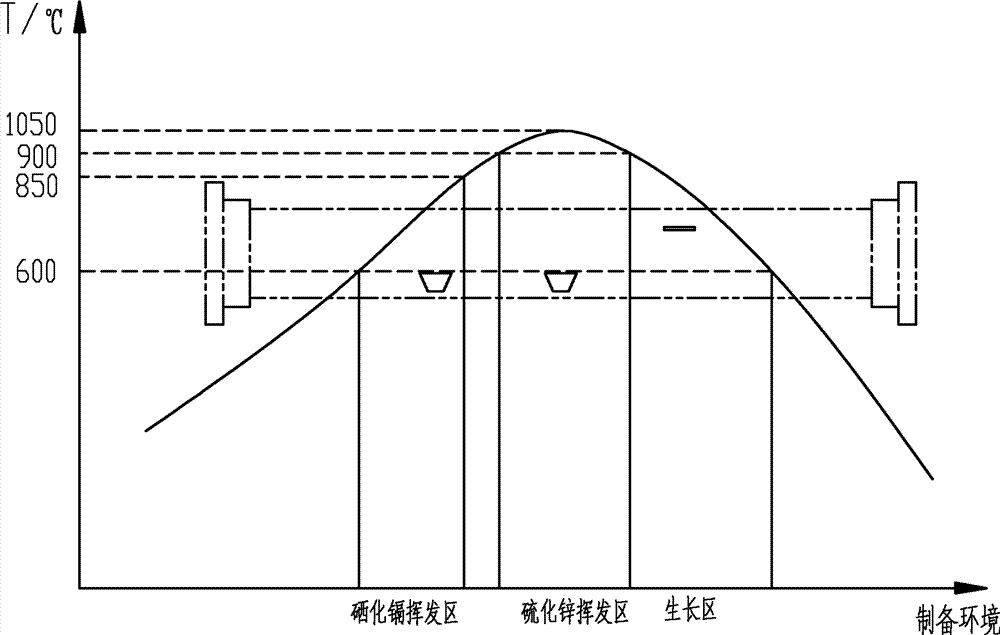

[0035] Get zinc sulfide 0.8g and put it into the first container 12, get cadmium selenide 0.4g and put it into the second container 13, the mass ratio of zinc sulfide and cadmium selenide is 2: 1, the first container 12 and The second container 13 is installed on the connecting rod 11, and the growth carrier is placed on the carrier platform 14. The growth carrier in this embodiment is a gold-plated silicon wafer, and the gold-plated thickness of the gold-plated silicon wafer is 5 nm. Adjust the positions of the first container 12, the second container 13 and the carrier platform 14, set the preparation temperature of zinc sulfide to 1000°C, and set the preparation temperature of cadmium selenide to 800°C. Vacuumize to keep the vacuum degree of the preparation environment in the box at 1.3kPa, and keep the nitrogen flow in the preparation environment at 100ml / min during the preparation process.

[0036] Turn on the high-temperature furnace 16 to heat, so that the temperature a...

Embodiment 2

[0040] The amount of zinc sulfide and cadmium selenide used in this example is both 0.3g, and the preparation temperature of zinc sulfide is 950°C, the preparation temperature of cadmium selenide is 750°C, and the carrier adopts a gold-plated silicon chip with a surface gold-plated thickness of 8nm. The vacuum degree of the preparation environment is 1.2kPa, and the nitrogen gas flow of the preparation environment is maintained at 100ml / min during the preparation process; heating, so that the temperature of the zinc sulfide reaches 950°C from room temperature 20°C in 18 minutes, correspondingly, at this time, the selenium The temperature of cadmium is 750°C, and the temperature at the high temperature end of the growth area is 900°C; after the temperature is reached, keep the position of the gold-plated silicon wafer unchanged for 9 minutes, and then move the gold-plated silicon wafer from the high-temperature end of the growth area at a speed of 1 cm / min. Move to the cooler en...

Embodiment 3

[0042] The amount of zinc sulfide and cadmium selenide used in this example is 1g and 0.2g respectively, and the preparation temperature of zinc sulfide is 900°C, the preparation temperature of cadmium selenide is 600°C, and the surface of the carrier is gold-plated with a thickness of 2nm. Ceramic sheet; the vacuum degree of the preparation environment is 30kPa, and the nitrogen flow of the preparation environment is kept at 500ml / min during the preparation process; heating, so that the temperature of zinc sulfide reaches from room temperature 20°C to 900°C in 30 minutes, correspondingly, at this time The temperature of cadmium selenide is 600°C, and the temperature at the high temperature end of the growth area is 900°C; after the temperature is reached, keep the position of the gold-plated ceramic sheet unchanged for 5 minutes, and then move the gold-plated silicon sheet from the high temperature of the growth area at a speed of 2cm / min. end to the lower end. The other prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com