Spherical-cavity microelectrode array biosensor and preparation method thereof

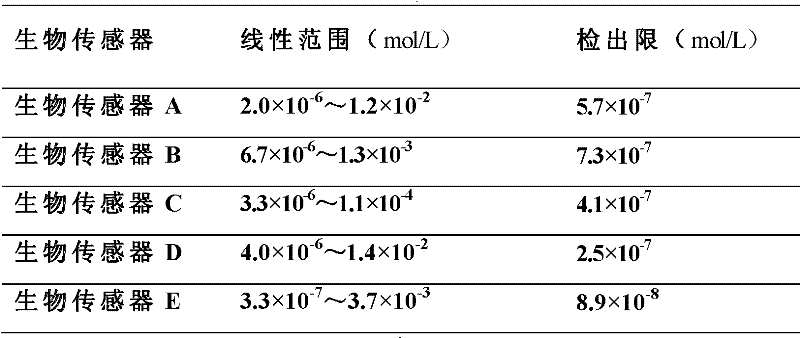

A microelectrode array and biosensor technology is applied in the field of preparation of spherical cavity microelectrode array biosensors to achieve the effects of improving signal-to-noise ratio, high sensitivity and increasing loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] For example, the platinum electrode was ultrasonically washed with acetone, ethanol, and water for 30 minutes and then stored in water. A polystyrene microsphere emulsion with a mass fraction of 1% was prepared with a 1:0.5 ethanol:water mixture as a solvent, and the size of the microspheres was 1500 nm. Using a mixture of water and ethanol with a volume ratio of 8.5:0.85 as the subphase, the polystyrene microsphere emulsion was slowly dripped onto the surface of the subphase. After standing for 15 minutes, the sliding barrier was compressed at a speed of 10 cm / min. When the membrane pressure reaches 10mN / m, keep the same membrane pressure for 30 minutes to stabilize the Langmuir membrane on the gas-liquid interface. The polystyrene microsphere array electrode was obtained by using the vertical pulling method to transfer it to the electrode at a speed of 1mm / min.

[0035] Mix 5mL of ethyl orthosilicate with 60mL of ethanol, put it in a constant temperature magnetic stirre...

Embodiment 2

[0038] The indium tin oxide electrode was ultrasonically washed with acetone, ethanol, and water for 30 minutes and then stored in water. A polystyrene microsphere emulsion with a mass fraction of 1% was prepared with a 1:1 ethanol:water mixture as a solvent, and the size of the microspheres was 1500 nm. Using a mixture of water and ethanol with a volume ratio of 8.5:1 as the subphase, the polystyrene microsphere emulsion was slowly dripped onto the surface of the subphase, and after standing for 20 minutes, the sliding barrier was compressed at a speed of 20 cm / min. When the membrane pressure reaches 14mN / m, keep the same membrane pressure for 30 minutes to stabilize the Langmuir membrane on the gas-liquid interface. The two-dimensional polystyrene microsphere array electrode is obtained by using the vertical pulling method to transfer it to the electrode at a speed of 1mm / min.

[0039] Prepare a mixture of 0.3mol / L zinc nitrate and 0.1mol / L citric acid, and heat the mixture to...

Embodiment 3

[0042] The glassy carbon electrode was ultrasonically washed with acetone, ethanol, and water for 30 minutes and then stored in water. A polystyrene microsphere emulsion with a mass fraction of 1% was prepared using a mixture of ethanol and water with a volume ratio of 1:1.5 as a solvent, and the size of the microspheres was 1500 nm. Using a mixture of water and ethanol with a volume ratio of 8.5:1.5 as the subphase, the polystyrene microsphere emulsion was slowly dripped onto the surface of the subphase, and after standing for 25 minutes, the sliding barrier was compressed at a speed of 30 cm / min. When the membrane pressure reaches 18mN / m, keep the same membrane pressure for 30 minutes to stabilize the Langmuir membrane on the gas-liquid interface. The two-dimensional polystyrene microsphere array electrode is obtained by using the vertical pulling method to transfer it to the electrode at a speed of 1mm / min.

[0043] Take 20mL of tetra-n-butyl titanate and add dropwise to 80mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com