Nucleating agent, its preparation method and application

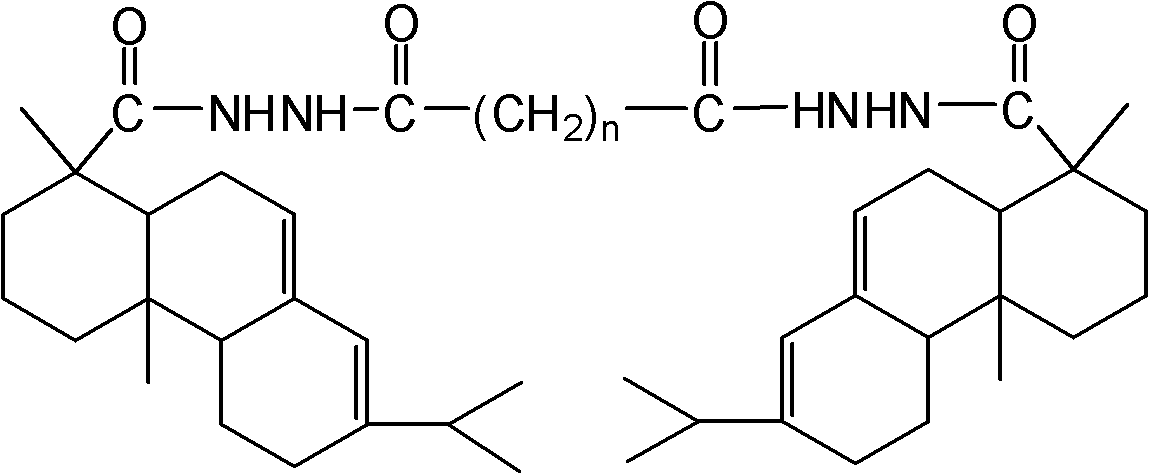

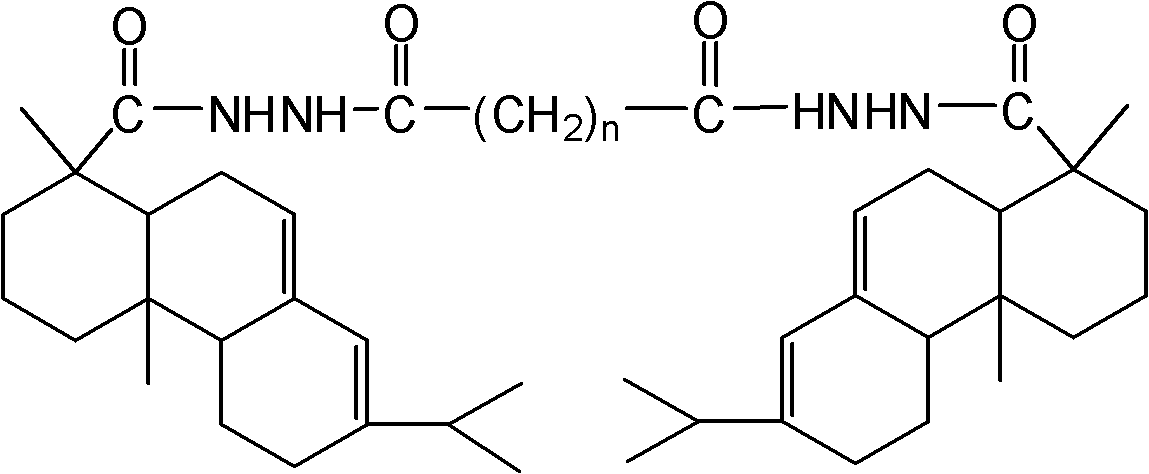

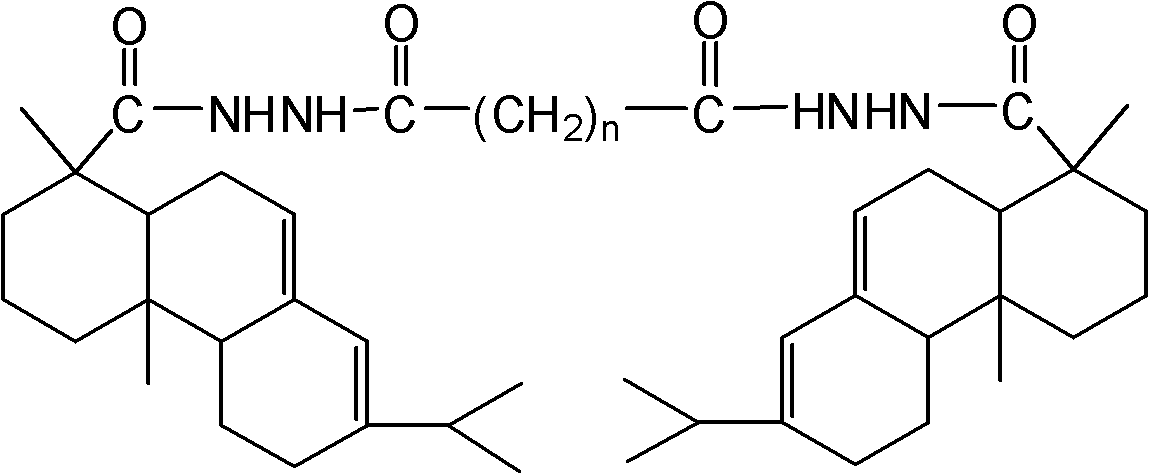

A technology of nucleating agent and auxiliary agent, applied in the field of polylactic acid rapid crystallization nucleating agent and its preparation, can solve the problems of insignificant crystallization nucleation ability, poor compatibility of polylactic acid matrix, insufficient crystal nucleation, etc. The effect of avoiding the decline of material mechanical properties, excellent mechanical properties, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051]In a 250 mL round bottom flask, add 100 mL of absolute ethanol and 1.5 mL of 98% concentrated sulfuric acid by mass, stir and shake well, add 6 g (19.87 mmol) of abietic acid, and heat to a temperature of 180° C. for 6 hours under reflux. Excess ethanol was distilled off under reduced pressure, and 50 mL of 5% sodium bicarbonate aqueous solution was added to the residue, and then the product was extracted with ether. The organic phase was washed with water first, and then with anhydrous MgSO 4 After drying, diethyl ether was distilled off to obtain 5.6 g of ethyl abietate, with a yield of 85.1%.

[0052] In a 250mL round bottom flask, add 5.6g (16.97mmol) of ethyl rosinate, 17mL of hydrazine hydrate with a mass percentage of 80% and 60mL of absolute ethanol, heat to 110°C and reflux for 3 hours. After cooling at room temperature, the precipitated crystals were suction-filtered, and the solid was dried to obtain 4.7 g of abietic acid carboxylhydrazide with a yield of 89%...

Embodiment 2

[0059] 500 grams of polylactic acid (2002D, LD mixed type, Nature Works), 5 grams of dodecanedioic acid disabietic hydrazide nucleating agent and 15 grams of auxiliary agents (1010 2.5 grams of antioxidant, 12.5 grams of lubricant aluminum stearate) , pre-mixed in a high-speed mixer with a rotation speed of 1500 rpm and then melt-extruded to obtain pellets. The melt-extrusion temperature is 190-200°C, and the extrusion temperatures of the first to sixth stages are 190°C, 192°C, 194°C, 195°C, 198°C, 200°C. The obtained pellets were injected into standard specimens of rapidly crystallizing polylactic acid plastics to be tested for tensile strength, notched impact strength and half-crystallization time. The semi-crystallization time is 0.78 minutes, the tensile strength is 71Mpa, and the notched impact strength is 4.1KJ / m 2 .

Embodiment 3

[0061] 500 grams of polylactic acid (2002D, LD mixed type, Nature Works), 0.5 grams of dodecanedioic acid birosin hydrazide nucleating agent and 15 grams of auxiliary agents (1010 2.5 grams of antioxidant, 12.5 grams of lubricant aluminum stearate) , pre-mixed in a high-speed mixer with a rotation speed of 1500 rpm and then melt-extruded to obtain pellets. The melt-extrusion temperature is 190-200°C, and the extrusion temperatures of the first to sixth stages are 190°C, 192°C, 194°C, 195°C, 198°C, 200°C. The obtained pellets were injected into standard specimens of rapidly crystallizing polylactic acid plastics to be tested for tensile strength, notched impact strength and half-crystallization time. The semi-crystallization time is 23 minutes, the tensile strength is 65Mpa, and the notched impact strength is 3.5KJ / m 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com